Continuous production process of hardware assembly

A production process and component technology, which is applied in the field of continuous production process of hardware components, can solve the problems of inability to handle rust prevention of workpieces, and achieve the effect of good synchronous movement, accurate installation hole position and good verticality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

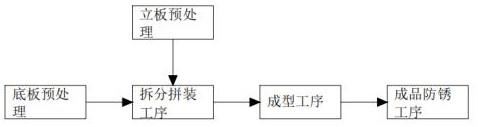

[0046] like Figures 1 to 5 As shown, a continuous production process of hardware components is characterized in that it comprises the following steps:

[0047] Step 1, base plate pretreatment, the base plate 20 is pre-machined to open splicing grooves and installation holes, and then placed on the base plate feeding group 5 one by one for transportation;

[0048] Step 2, the pretreatment of the vertical board, the vertical board 10 is drilled and cut by machining in advance, and then stacked and placed on the operating platform 11 of the vertical board feeding group 1;

[0049]Step 3, the disassembly and assembly process, the disassembly unit 13 laterally separates the two stacked vertical panels 10 into a group, and then the push unit 12 synchronously pushes the two vertical panels 10 forward, and the two vertical panels 10 are respectively received by the receiving parts a23 and the receiving part b24 take over, and when the dismantling unit 13 laterally separates the vert...

Embodiment 2

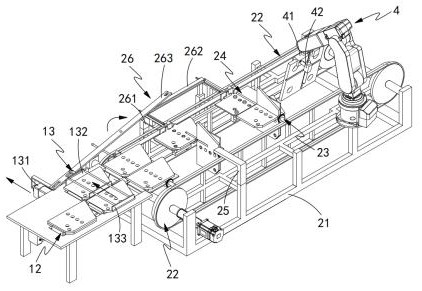

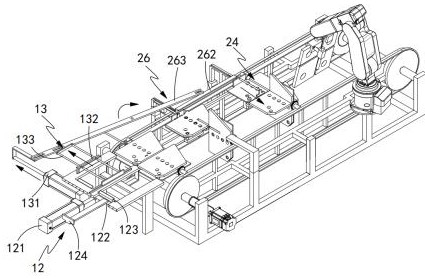

[0060] like figure 2 , 3 , 4, 5 and 16, a metal base tailor welding anti-rust integrated machine for mechanical equipment, including a feeding mechanism and a slotting mechanism 3, is characterized in that it also includes:

[0061] Flatten body 2;

[0062] finished product gripping device 7; and

[0063] Finished product conveyor line 8;

[0064] The feeding mechanism provides a riser 10 and a bottom plate 20 to the splicing mechanism 2, and the splicing mechanism 2 splices and welds two risers 10 and a bottom plate 20 into a whole;

[0065] The finished product grasping device 7 grasps the welded finished product for antirust work, and then transmits it to the finished product conveying line 8 for output.

[0066] Further, the feeding mechanism includes:

[0067] Riser Feed Group 1; and

[0068] Bottom plate feeding group 5;

[0069] The vertical plate feeding group 1 includes a propulsion unit 12 and a dismantling unit 13, the propelling unit 12 pushes two vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com