Automatic nut pushing device for mechanical assembly

A technology for pushing devices and nuts, which is applied in metal processing equipment, metal processing, manufacturing tools, etc. It can solve the problems of reduced work efficiency, nuts are easy to block the lower barrel, and increase labor intensity, so as to improve work efficiency and increase stability. sex, efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

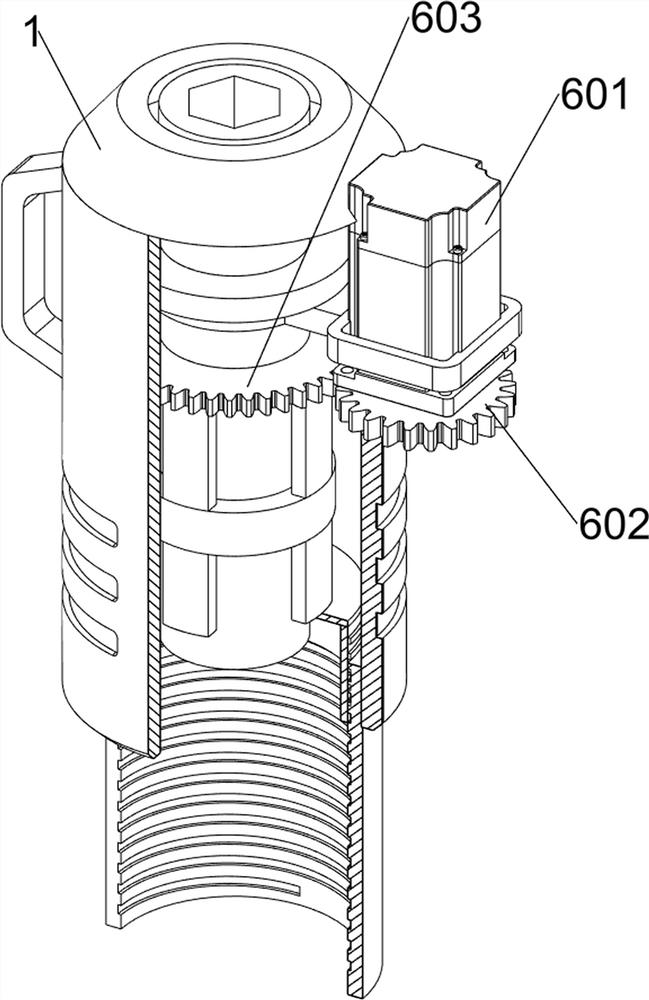

[0037] An automatic nut pushing device for mechanical assembly, such as Figure 1-Figure 9 As shown, it includes a casing 1, a first start button 2, a second start button 3, a third start button 4, a driving assembly 6, a clamping assembly 7 and a limit assembly 8, and the upper front side of the casing 1 is installed with a first start button. Button 2, the second start button 3 is installed on the front side of the upper part of the shell 1, and the second start button 3 is located below the first start button 2, and the third start button 4 is installed on the front side of the upper part of the shell 1, and the third start button 4 is located on the second Below the start button 3 , the housing 1 is provided with a driving assembly 6 , and the inner lower side of the driving assembly 6 is connected with a clamping assembly 7 , and a limiting assembly 8 is installed between the clamping assembly 7 and the driving assembly 6 .

[0038]The driving assembly 6 also includes a f...

Embodiment 2

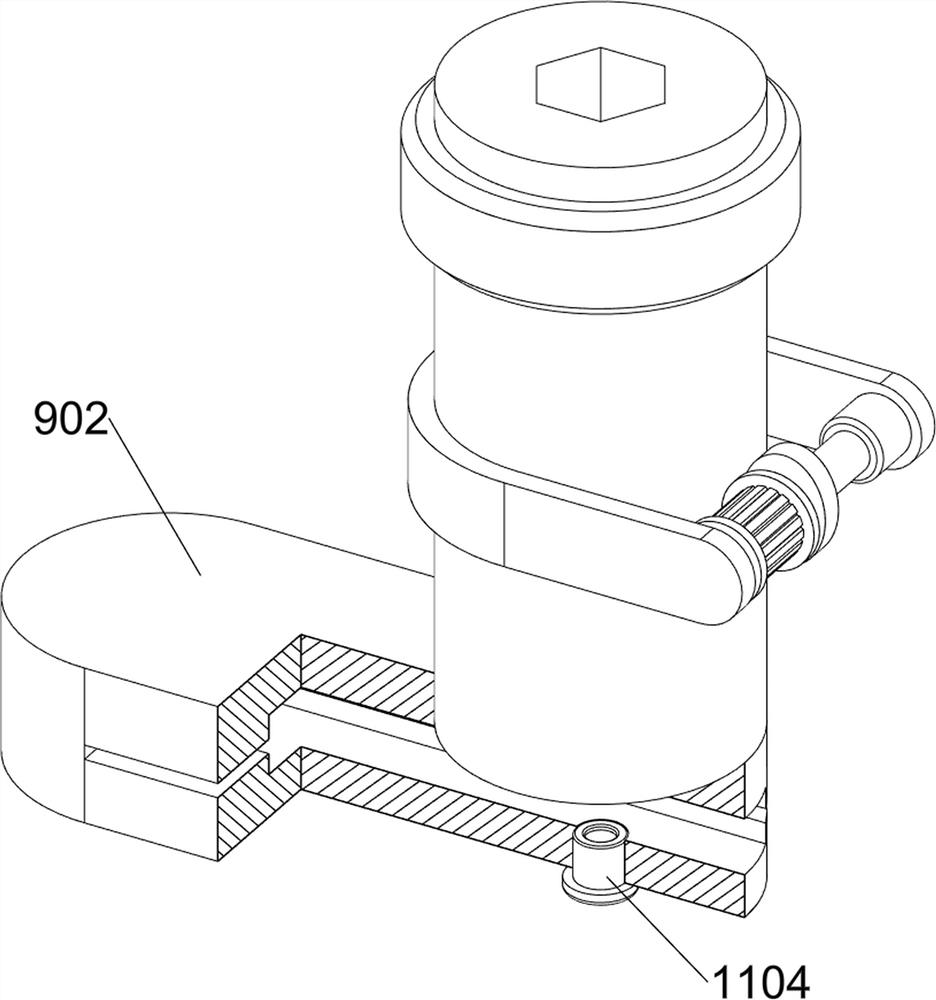

[0043] On the basis of Example 1, such as Figure 10-Figure 17 As shown, the blanking assembly 9 is also included, and the blanking assembly 9 also includes a blanking chute 901, a connecting block 902, an electromagnet 903, a metal block 904, a third slide bar 905, a third spring 906 and a pushing block 907, A connection block 902 is installed on the top of the casing 1, a feeding chute 901 is arranged on the right side of the top of the connection block 902, an electromagnet 903 is installed on the left side of the connection block 902, and a third slide bar 905 is fixedly connected to the front and rear sides of the connection block 902. A metal block 904 is slidably connected between the right side of the slide bar 905, and the metal block 904 and the electromagnet 903 are attracted to each other. A third spring 906 is connected between the metal block 904 and the third slide bar 905, and the third spring 906 is wound around On the third slide bar 905 , a pushing block 907...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com