Thermal power peak regulation system based on solid oxide fuel cell, and working method thereof

A technology of solid oxides and fuel cells, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of limited peak-shaving depth of large-scale units, to improve work capacity, ensure efficiency, increase regulation Effect of peak depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

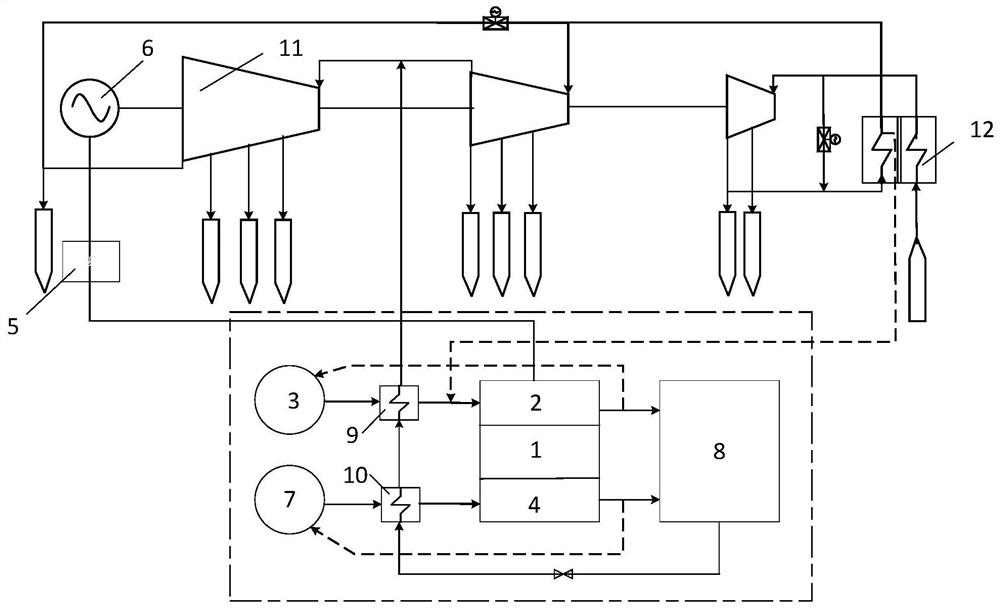

[0020] see figure 1 , a thermal power peak shaving system based on solid oxide fuel cells, including a solid oxide fuel cell 1, the cathode 2 of the solid oxide fuel cell 1 is connected to a hydrogen tank 3 and a reheat steam outlet pipe, and the reheat steam is reheated from a boiler 12 The hot steam is drawn from the side (temperature exceeds 600° C.), the anode 4 of the solid oxide fuel cell 1 is connected to the oxygen tank 7 , the solid oxide fuel cell 1 is connected to the inverter 5 , and the inverter 5 is connected to the generator 6 . Both the cathode 2 and the anode 4 of the solid oxide fuel cell 1 are connected to a catalytic combustion chamber 8 . A cathode heat exchanger 9 is provided on the pipeline between the hydrogen tank 3 and the cathode 2 of the solid oxide fuel cell 1 , and an anode heat exchanger 10 is provided on the pipeline between the oxygen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com