Zero-cold-water pressurization method for gas water heater

A technology of gas water heaters and zero cold water, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of poor overall effect, achieve the effects of reducing errors, facilitating operation, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

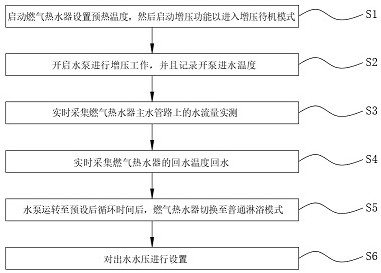

[0023] A method for zero-cooled water boosting of a gas water heater, specifically comprising the following steps:

[0024] S1. Start the preset function of the gas water heater, set the preheating temperature for preheating, and then start the boost function to enter the boost standby mode. When the current water flow is greater than the preset start water flow, start the ignition;

[0025] S2. Turn on the water pump for boosting work, and record the water inlet temperature when the pump is turned on, and keep the working power of the booster pump unchanged at this time;

[0026] S3. Collect the measured water flow on the main water pipeline of the gas water heater in real time. Once the measured water flow is greater than the preset start-up water flow, turn off the booster pump and the gas water heater enters the preheating mode. When it is detected again that the measured water flow is less than the preset water flow When the startup water flow is turned on, the booster pu...

Embodiment 2

[0032] A method for zero-cooled water boosting of a gas water heater, specifically comprising the following steps:

[0033] S1. Start the preset function of the gas water heater, set the preheating temperature for preheating, and then start the boost function to enter the boost standby mode. When the current water flow is greater than the preset start water flow, start the ignition;

[0034] S2. Turn on the water pump for boosting work, and record the water inlet temperature when the pump is turned on, and keep the working power of the booster pump unchanged at this time;

[0035] S3. Collect the measured water flow on the main water pipeline of the gas water heater in real time. Once the measured water flow is greater than the preset start-up water flow, turn off the booster pump and the gas water heater enters the preheating mode. When it is detected again that the measured water flow is less than the preset water flow When the startup water flow is turned on, the booster pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com