Marine steam turbine rotor field dynamic balance structure

An on-site dynamic balancing, steam turbine rotor technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve problems such as affecting safe operation, intensifying steam turbine vibration, and increasing rotor unbalanced mass, saving long-term maintenance and improving. The effect of dynamic balance accuracy and high cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

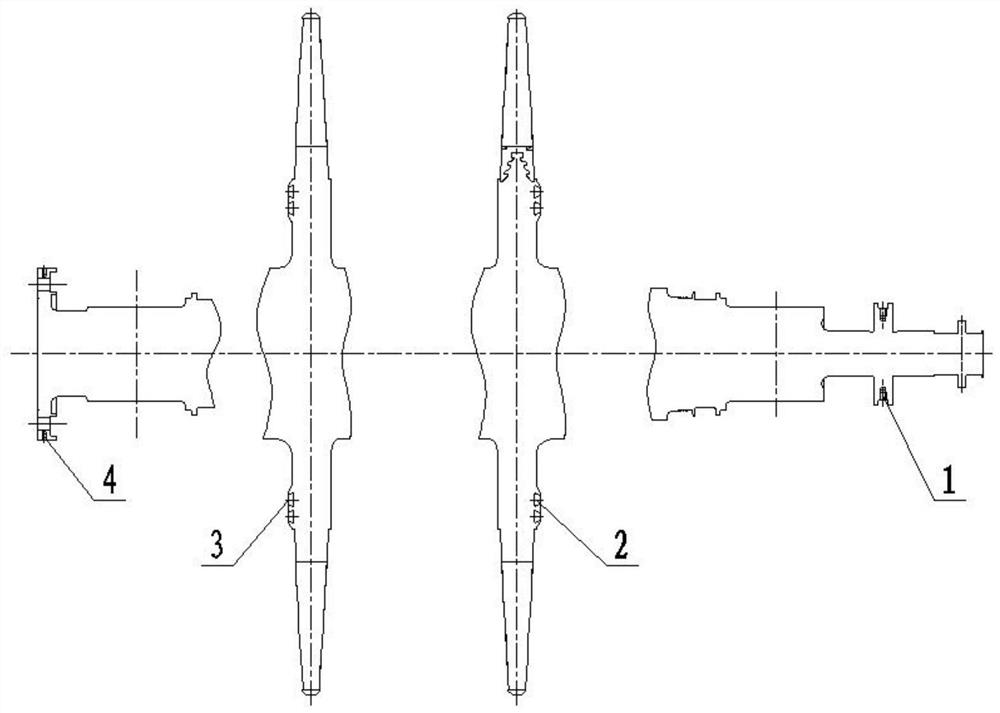

[0019] combine Figure 1-2 , using multiple positions of the steam turbine rotor for on-site dynamic balance structure design, on-site dynamic balance structure settings on the steam turbine rotor thrust disc, coupling output flange, rotor first-stage disc and last-stage disc, fully combined The bearing box cover, coupling cover, cylinder manhole and other structures make the operation feasible and meet the on-site dynamic balance requirements when the dynamic balance is greatly damaged.

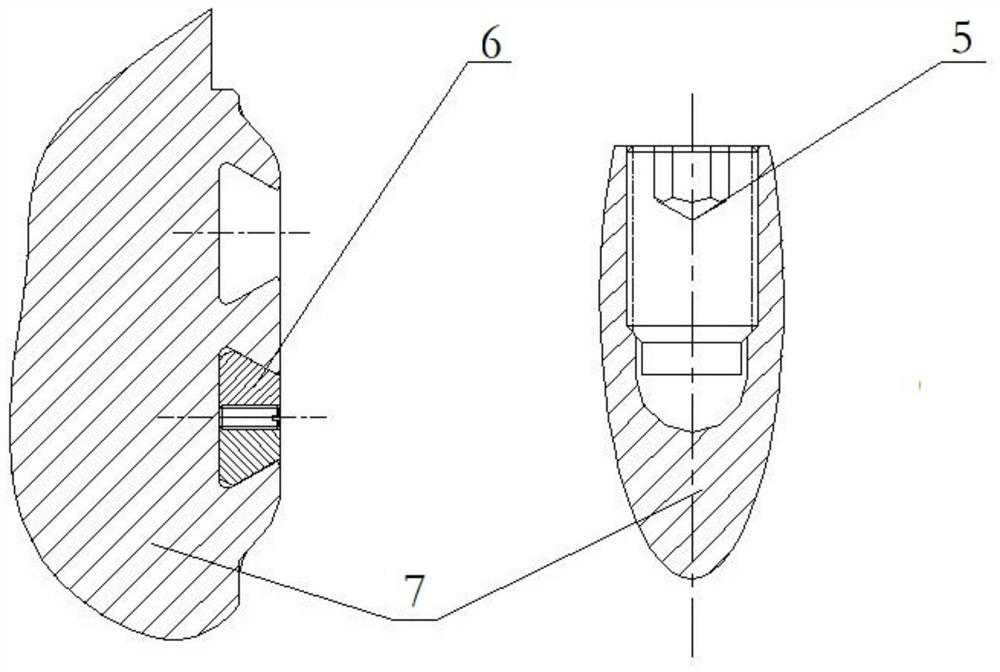

[0020] The new on-site dynamic balance structure is designed inside the factory dynamic balance groove of the last stage of the rotor, so that it can be as close as possible to the final blade in the radial direction without affecting the structural strength of the wheel and the function of the high-speed dynamic balance groove for factory use, while ensuring its Operability, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com