Wooden door with air humidifying and purifying functions and preparation process thereof

A preparation process and functional technology, applied in the field of wooden doors and its preparation, can solve problems such as cracking of wooden boards and poor sealing of the processing environment, and achieve the effects of preventing emission, avoiding poor usability, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

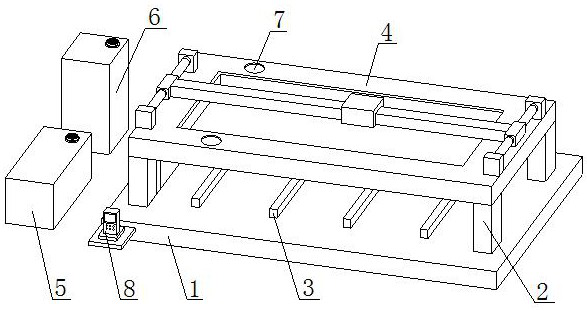

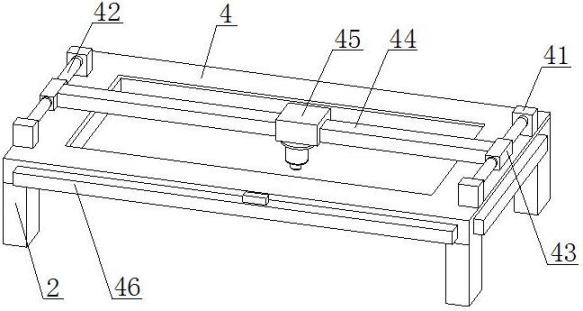

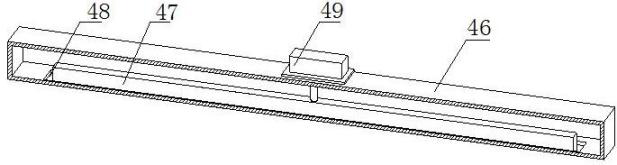

[0031] see Figure 1-Figure 6 As shown, in the first aspect, the present invention provides a wooden door with air humidification and purification functions, including a processing base 1, the top of the processing base 1 is fixedly connected with a hydraulic support 2 and a support block 3, and the outer wall of the support block 3 is opened There are air circulation holes 31, the air circulation holes 31 can promote the circulation of air, increase the reaction efficiency of air molecules and wood boards, the top of the hydraulic support 2 is fixedly connected with the processing board 4, and the top of the processing board 4 is provided with a connecting pipe hole 7, connected The mouth of the pipe hole 7 is connected with the humidification box 5, the purification box 6 and the output end by a pipeline, and the connecting pipe hole 7 is symmetrically arranged on the top of the processing plate 4, and a controller 8 is arranged on the front of the processing base 1 to contro...

Embodiment 2

[0033] see figure 1 , Figure 5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: In this embodiment, the inner wall of the humidification box 5 is provided with a first blower 51, an air inlet pipe 52, a first filter box 53, water The mist conversion box 54 and the water tank 55, the water mist conversion box 54 that is set is convenient to convert the water droplets inside the water tank 55 into water molecules, so that it can be evenly sprayed on the surface of the plank, and the bottom of the first blower 51 passes through the air inlet pipe provided 52 is connected with the first filter box 53 pipelines, the right side of the first filter box 53 is connected with the left side pipeline of the water mist conversion box 54, the bottom of the water tank 55 is connected with the left side pipeline of the water mist conversion box 54, and the humidification box 5 The top of the spray hole 56 is provided with a spray hole 56, and the ...

Embodiment 3

[0035] see figure 1 , Image 6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the inner wall of the purification box 6 is provided with a liquid addition box 61, a second filter box 62, a second blower 63, Purification holes 64, filter plates 65, micro-static purification plates 66 and sliding steps 67, the liquid addition box 61 provided is convenient to change the molecular composition of the processing environment, which is conducive to better adhesion of the wood board, the bottom of the liquid addition box 61 It is connected with the left side pipeline of the second filter box 62, and the bottom of the purification hole 64 is connected with the top pipeline of the second filter box 62, and the second filter box 62 provided prevents the generation of harmful molecules during processing, so that it can be purified. Prevent hazards to the health of workers.

[0036]In addition, the upper and lower ends of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com