Heavy oil viscosity reduction and desulfurization method based on supercritical methanol

A supercritical methanol and heavy oil technology, which is applied in the fields of hydrocarbon oil cracking, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of low conversion rate, easy coking of the system, harsh reaction conditions of supercritical fluid processing technology, etc., and achieve the reduction of sulfur and nitrogen The effect of equal heteroatom content, increasing conversion rate and avoiding coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0063] Raw material heavy oil properties

[0064]

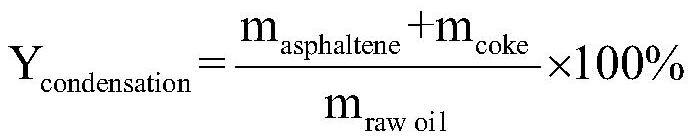

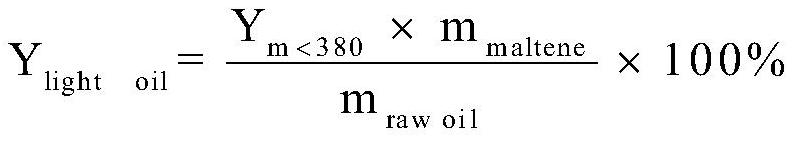

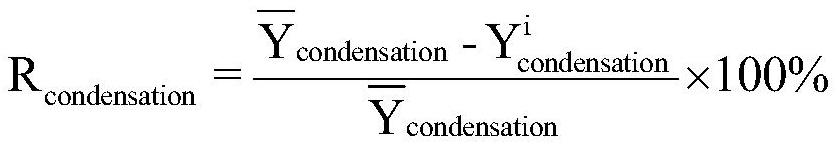

[0065] The reaction temperature is 350°C, the reaction pressure is maintained at 15-22MPa, the reaction time is 60min, the stirring rate is 900rpm, the mass ratio of alcohol to oil is 1:1; the yield of light components is 75wt%, the yield of asphaltene is 21wt%, residual coke is almost negligible, and the mass Conservation 95%. After testing, under the optimal conditions, the content of light product components kept below 350°C is 61wt%, and the viscosity (80°C) drops to 76mPa·s; the S content of the oil product decreases by 37wt%.

[0066] The structural changes of asphaltenes in heavy oil during the reaction were studied by infrared spectroscopy. It shows that the raw material asphaltene undergoes a certain cracking reaction under high temperature conditions, and a certain amount of secondary asphaltenes are produced.

[0067] After thermogravimetric infrared detection, supercritical methanol participated in the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com