Low-dielectric and high-thermal-conductivity composite film material and preparation method thereof

A composite film, high thermal conductivity technology, applied in the direction of film/sheet adhesive, non-polymer adhesive additive, adhesive additive, etc., can solve the problem that the heat dissipation film cannot meet the requirements of insulation and low dielectric, and cannot meet the Problems such as mobile phone antenna heat dissipation requirements and low dielectric performance requirements are not met, and it is suitable for large-scale industrialization, mature coating technology, and convenient grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] Example 1

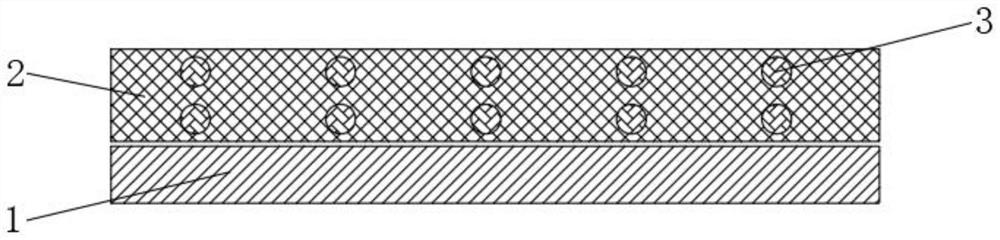

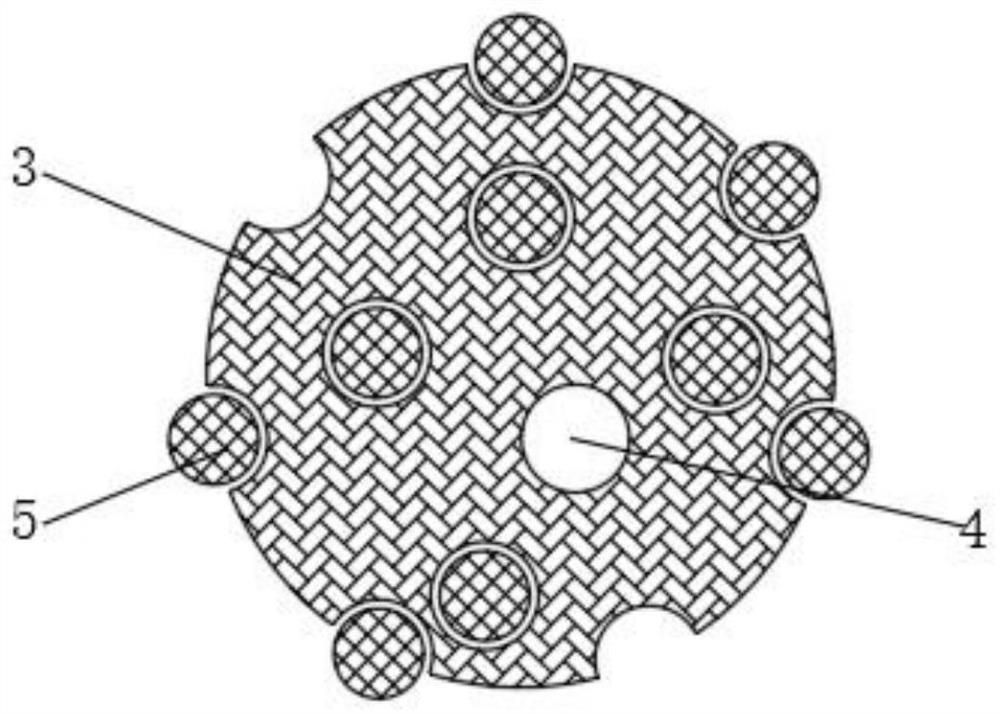

[0031] see Figure 1-2 , the present invention provides a technical solution: a composite film material with low dielectric and high thermal conductivity, comprising a resin layer 1, a ceramic composite layer 2, ceramic particles 3, pores 4 and ceramic particles 5, and the top of the resin layer 1 is laid and connected with The ceramic composite layer 2 has ceramic particles 3 distributed on one side of the ceramic composite layer 2 , pores 4 are distributed on one side of the ceramic particles 3 , and ceramic particles 5 are sheathed on one side of the pores 4 .

[0032] Preferably, the resin layer is resin, including two or more of polyimide resin, alkyl phenolic resin, xylene resin, and curable silicone resin, and the thickness of the resin layer is 10-50 μm.

[0033] Optimized, the ceramic composite layer is a uniform mixture of a resin substrate and ceramic particles, wherein the resin substrate includes two or more of polyimide resin, alkyl phenolic r...

Example Embodiment

[0069] Embodiment 2

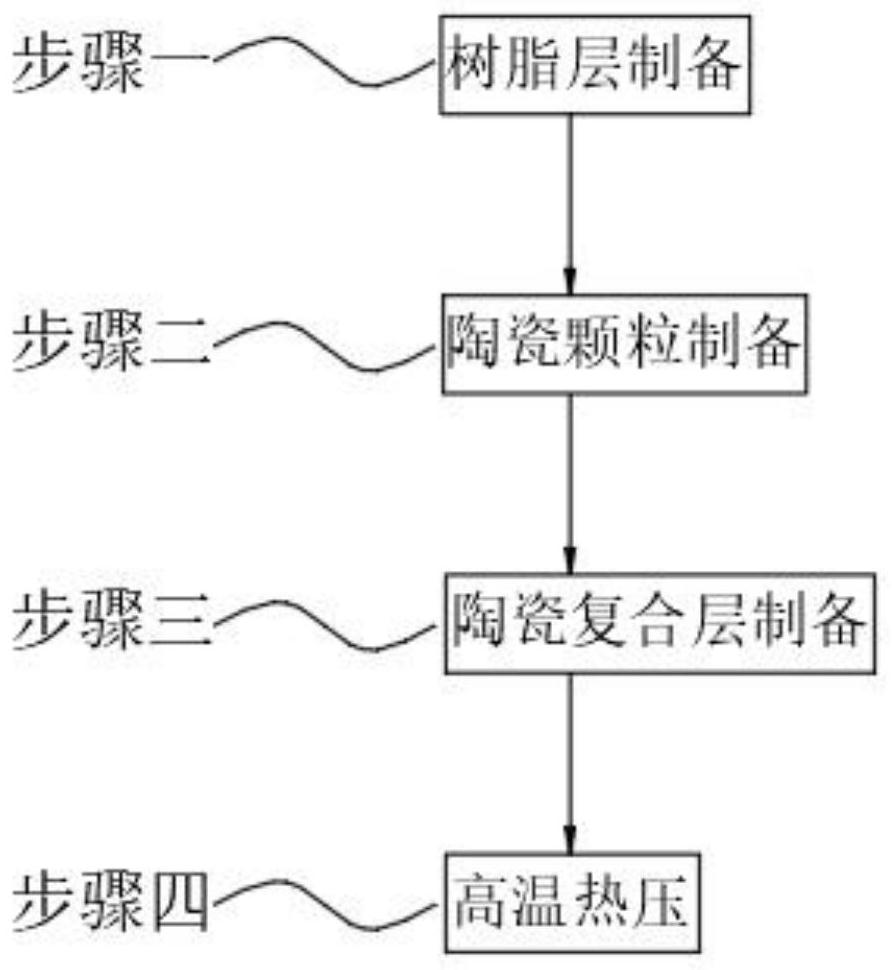

[0070] see image 3 , a preparation method of composite film material, comprising the following steps: step 1, resin layer preparation; step 2, ceramic particle preparation; step 3, ceramic composite layer preparation; step 4, high temperature hot pressing,

[0071] In step 1, after mixing the resin raw materials, and adding ethyl acetate to the raw materials as a grinding medium, then using a grinding disperser to grind the raw materials for the first time, so that the rotation speed is 10-500 rpm, and the grinding time is 0.5- 4H, then pour the resin into the molding box, and then use the scraper to coat the resin, so that the dry film thickness is 20 ~ 80μm, and finally the dry film is placed in the tunnel drying furnace, so that the drying temperature is 80 ~ 260 ℃, the drying time is 1-3H, so that the resin layer is obtained after drying;

[0072] In the second step, after the ceramic raw materials are mixed, toluene is put into the raw material as...

Example Embodiment

[0075] Embodiment 3

[0076] see Figure 4-6 , in step 3, the grinding and dispersing machine includes a dispersing machine main body 01, a supporting frame 02 and a quantitative feeding assembly 03, the top outer wall of the dispersing machine main body 01 is welded and fixed with a supporting frame 02, and one side inner wall of the supporting frame 02 is fixed with a quantitative feeding Feed assembly 03;

[0077] Quantitative feeding assembly 03 includes moving groove 031, chute 032, air cylinder 033, limit plate 034, support plate 035, aggregate funnel 036, quantitative cup 037, slider 038, rotating plate 039 and baffle 0310, support frame 02 There is a moving groove 031 on the inner wall of one side, a quantitative cup 037 is installed on one side of the moving groove 031, a slider 038 is symmetrically welded and fixed on the outer wall of one side of the quantitative cup 037, and the inner walls on both sides of the moving groove 031 are correspondingly sliding Each blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com