High-fluidity lightweight high-strength concrete and preparation method thereof

A high-strength concrete and high-fluidity technology, which is applied in the field of building materials, can solve the problems of loose accumulation of aggregate and cementitious material particles, large particle size of coarse aggregate and pottery sand, and high apparent density of concrete. The effect of high apparent density, low preparation cost, and improved fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

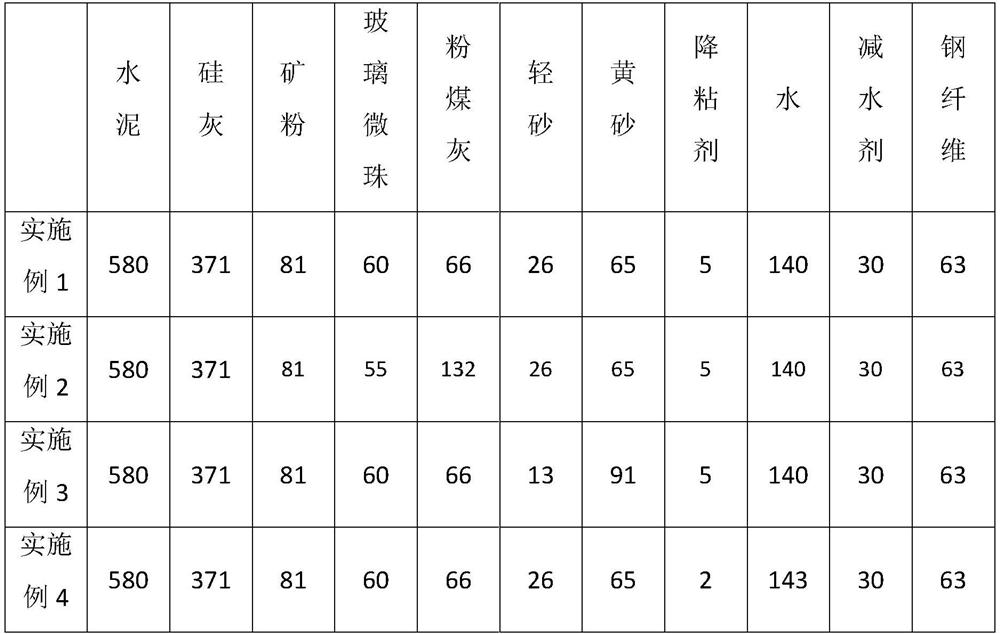

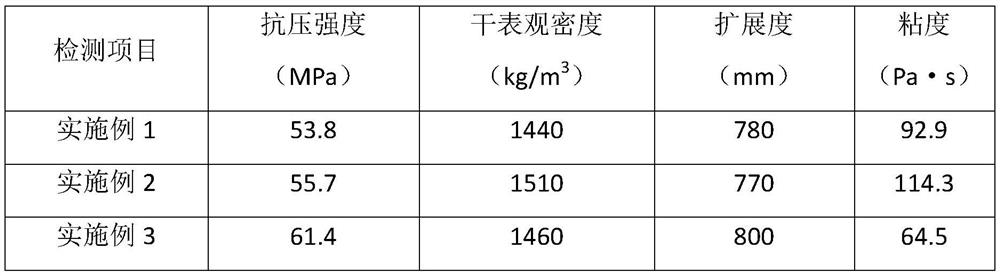

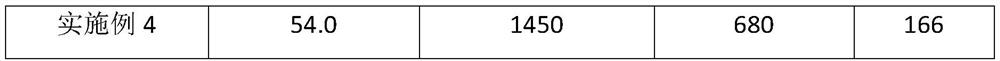

Embodiment 1

[0027] A kind of high-fluidity lightweight high-strength concrete obtained by the following preparation steps:

[0028] Step 1. Mix 580 parts of cement, 371 parts of silica fume, 81 parts of mineral powder, 60 parts of glass beads, 66 parts of fly ash, 26 parts of light sand and 65 parts of yellow sand under mechanical stirring Evenly, dry material A1 is obtained;

[0029] Step 2. Pour 30 parts of water reducer and 5 parts of viscosity reducer into 140 parts of water and stir evenly, then add to dry material A1 and mix evenly to obtain slurry B1;

[0030] Step 3: Add 63 parts of steel fibers into the slurry B1 along the stirring direction, and stir evenly to obtain high-fluidity lightweight high-strength concrete.

Embodiment 2

[0032] A kind of high-fluidity lightweight high-strength concrete obtained by the following preparation steps:

[0033] Step 1. Mix 580 parts of cement, 371 parts of silica fume, 81 parts of mineral powder, 55 parts of glass beads, 132 parts of fly ash, 26 parts of light sand and 65 parts of yellow sand under mechanical stirring Evenly, dry material A2 is obtained;

[0034] Step 2. Pour 30 parts of water reducer and 5 parts of viscosity reducer into 140 parts of water and stir evenly, then add to dry material A2 and mix evenly to obtain slurry B2;

[0035] Step 3: Add 63 parts of steel fibers into the slurry B2 along the stirring direction, and stir evenly to obtain high-fluidity lightweight high-strength concrete.

Embodiment 3

[0037] A kind of high-fluidity lightweight high-strength concrete obtained by the following preparation steps:

[0038] Step 1. Mix 580 parts of cement, 371 parts of silica fume, 81 parts of mineral powder, 60 parts of glass beads, 66 parts of fly ash, 13 parts of light sand and 91 parts of yellow sand under mechanical stirring Evenly, dry material A3 is obtained;

[0039] Step 2. Pour 30 parts of water reducer and 5 parts of viscosity reducer into 140 parts of water and stir evenly, then add to dry material A3 and mix evenly to obtain slurry B3;

[0040] Step 3: Add 63 parts of steel fibers into the slurry B3 along the stirring direction, and stir evenly to obtain high-fluidity lightweight high-strength concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com