Synchronous punching mechanism

A synchronous, punching device technology, applied in the direction of metal processing, etc., can solve the problems such as the paper dust discharge mechanism is not smooth, can not be completely cleaned, does not have multiple holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

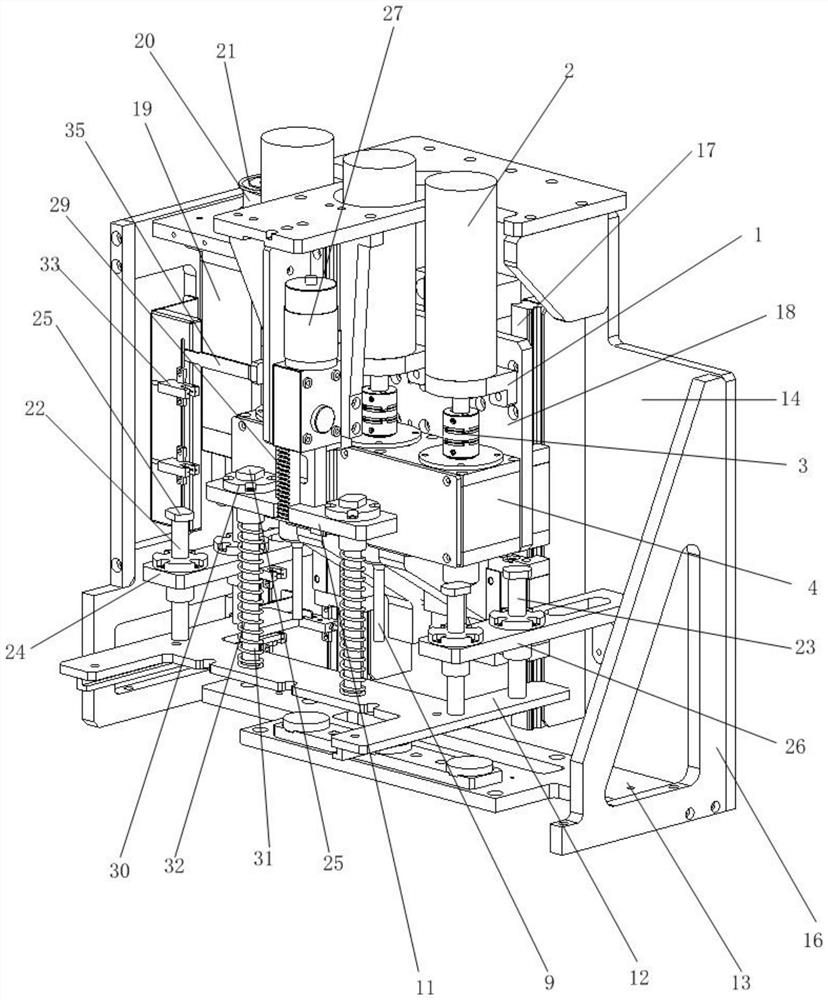

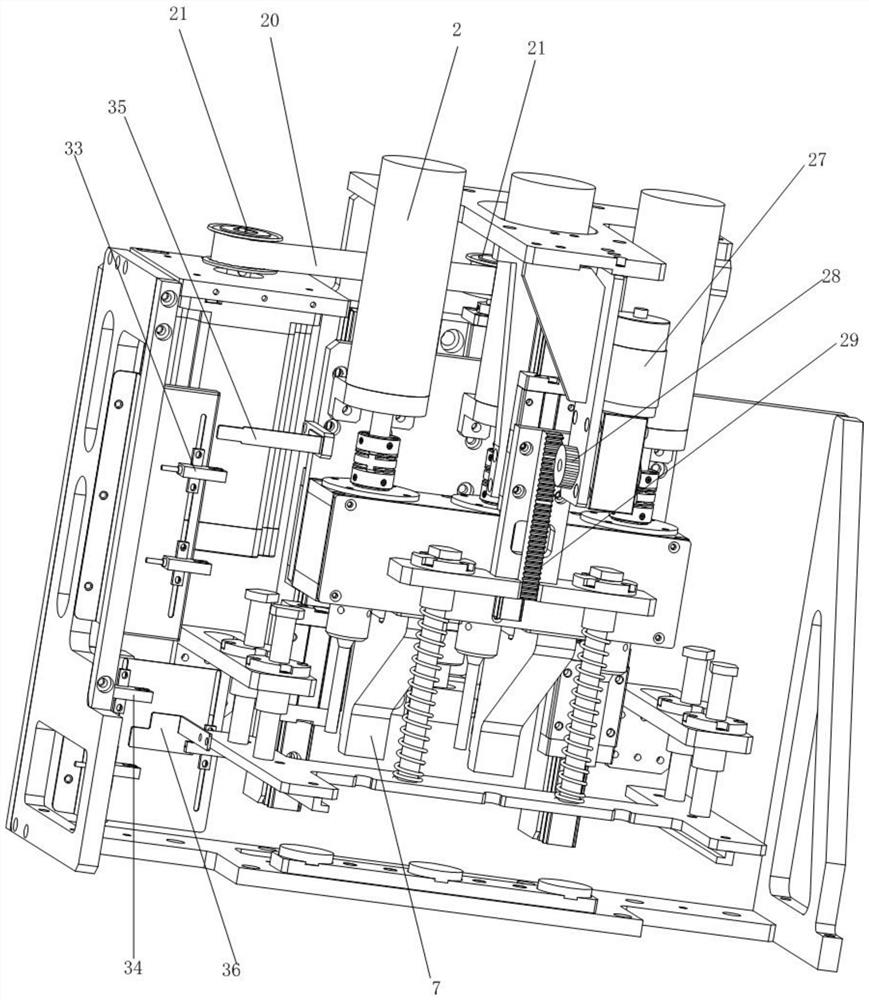

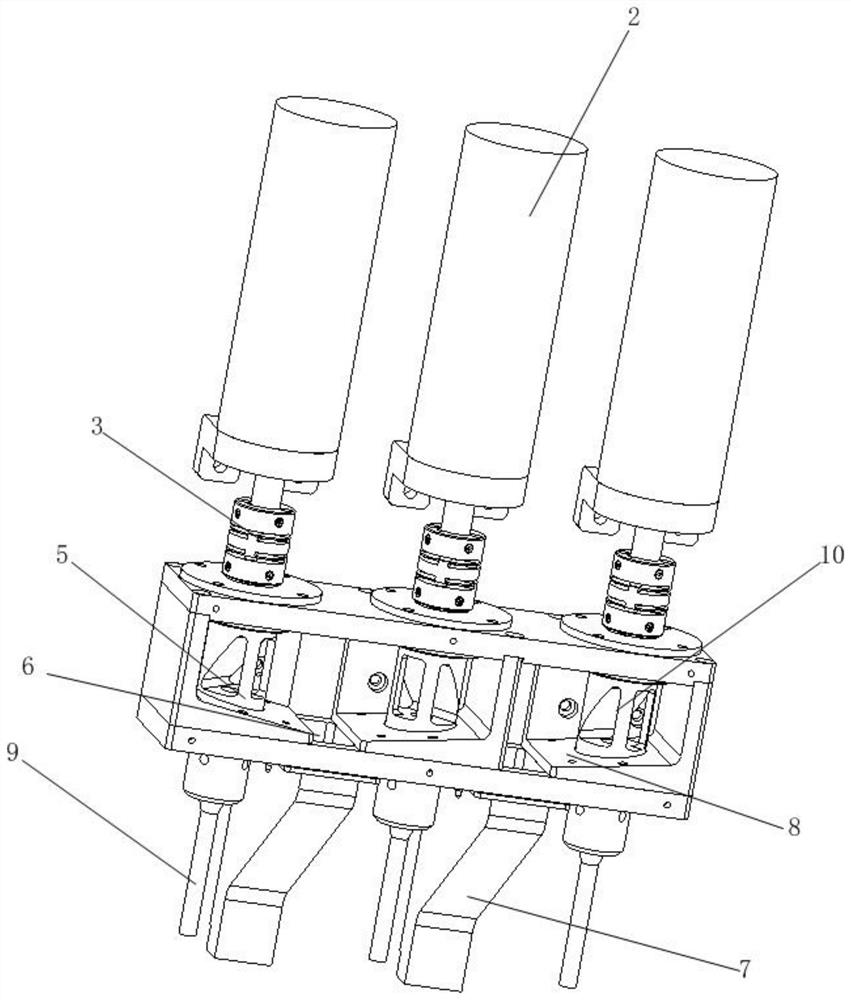

[0051] In this specific example Figure 1 to Figure 5The shown synchronous punching mechanism includes a frame, a paper pressing device installed in the frame, and a punching device installed on the backboard 18 in the frame. The punching device includes a vertical board 1 fixed on the backboard 18 And several DC motors 2 erected on the vertical plate 1, each DC motor 2 is connected with a hollow punching shaft 5 located in the paper scrap collection box 4 through a coupling 3, and the adjacent punched holes are located in the paper scrap collection box 4 The inner bottom surface between the shafts 5 is provided with a paper dust collection port 6, each paper dust collection port 6 is connected with a deflector 7, and the bottom bearing of each perforated shaft 5 is fixed on one side of the paper dust collection port 6 and The paper scraps are directed to the drainage block 8 of the paper scrap collection port 6, the bottom end of the punching shaft 5 is connected with a hollo...

Embodiment 2

[0055] In this specific example Figure 1 to Figure 5 The shown synchronous punching mechanism includes a frame, a paper pressing device installed in the frame, and a punching device installed on the backboard 18 in the frame. The punching device includes a vertical board 1 fixed on the backboard 18 And several DC motors 2 erected on the vertical plate 1, each DC motor 2 is connected with a hollow punching shaft 5 located in the paper scrap collection box 4 through a coupling 3, and the adjacent punched holes are located in the paper scrap collection box 4 The inner bottom surface between the shafts 5 is provided with a paper dust collection port 6, each paper dust collection port 6 is connected with a deflector 7, and the bottom bearing of each perforated shaft 5 is fixed on one side of the paper dust collection port 6 and The paper scraps are directed to the drainage block 8 of the paper scrap collection port 6, the bottom end of the punching shaft 5 is connected with a holl...

Embodiment 3

[0059] In this specific example Figure 1 to Figure 5 The shown synchronous punching mechanism includes a frame, a paper pressing device installed in the frame, and a punching device installed on the backboard 18 in the frame. The punching device includes a vertical board 1 fixed on the backboard 18 And several DC motors 2 erected on the vertical plate 1, each DC motor 2 is connected with a hollow punching shaft 5 located in the paper scrap collection box 4 through a coupling 3, and the adjacent punched holes are located in the paper scrap collection box 4 The inner bottom surface between the shafts 5 is provided with a paper dust collection port 6, each paper dust collection port 6 is connected with a deflector 7, and the bottom bearing of each perforated shaft 5 is fixed on one side of the paper dust collection port 6 and The paper scraps are directed to the drainage block 8 of the paper scrap collection port 6, the bottom end of the punching shaft 5 is connected with a holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com