Optical system for debugging hyperspectral imaging subsystem instead of coaxial three-reflector system

A hyperspectral imaging, coaxial three-mirror technology, applied in optics, optical components, instruments, etc., can solve the problems of long development cycle of hyperspectral imaging system, large aperture of front objective lens, long processing cycle, etc., to improve installation and adjustment The effect of testing ability, reducing the difficulty of installation and adjustment, and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is further explained below in conjunction with the accompanying drawings and embodiments.

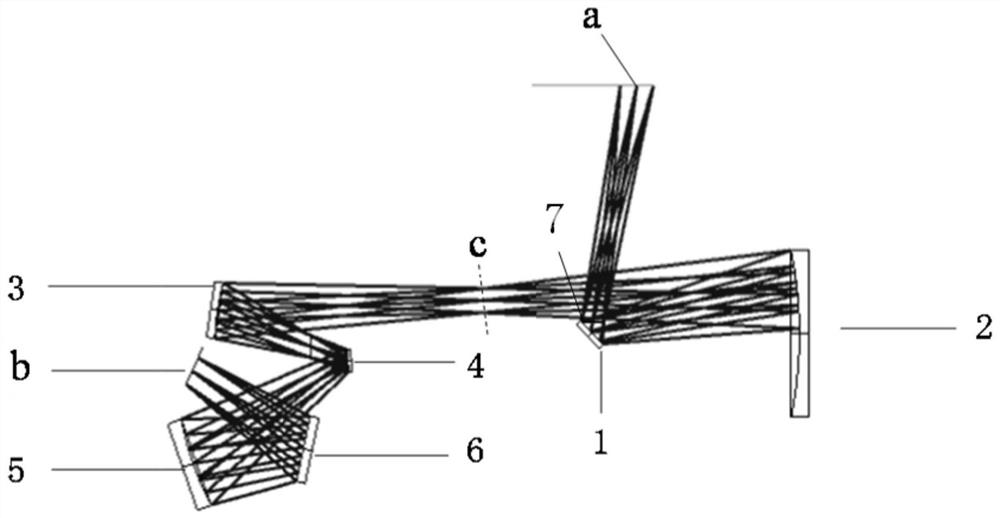

[0041] An alternative anti triax system hyperspectral imaging optical subsystem debug system (hereinafter referred to as an optical system for debugging), comprising a object plane and the image plane B, and the aperture 7 along the optical path between the two successively disposed, a focusing mirror, a first spherical reflector 2, a second spherical mirror 3, a third spherical mirror 4, the fourth spherical mirror 5 and the planar mirror 6; a first focusing lens and a spherical mirror consistent with the structure parameters of a spherical reflector 2 before the original anti triax system focusing mirror and the focusing mirror, spherical mirror 3 and the second, third spherical mirror 4, and the fourth spherical mirror 5 a plane mirror 6, form a folded three off-axis system, instead of the original anti-anti triax remaining lens system; wherein a stop is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com