Differential shell detection auxiliary tool

A technology for auxiliary tooling and differentials, which is applied in the direction of measuring devices, testing of machine/structural components, testing of machine gears/transmission mechanisms, etc. It can solve the problem that the measuring probe cannot reach the measurement, the detection data is not systematic, and the support method cannot be realized. Complete the inspection items and other issues at one time to achieve the effect of rapid batch detection, convenient collection of statistics and analysis, and real-time monitoring of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

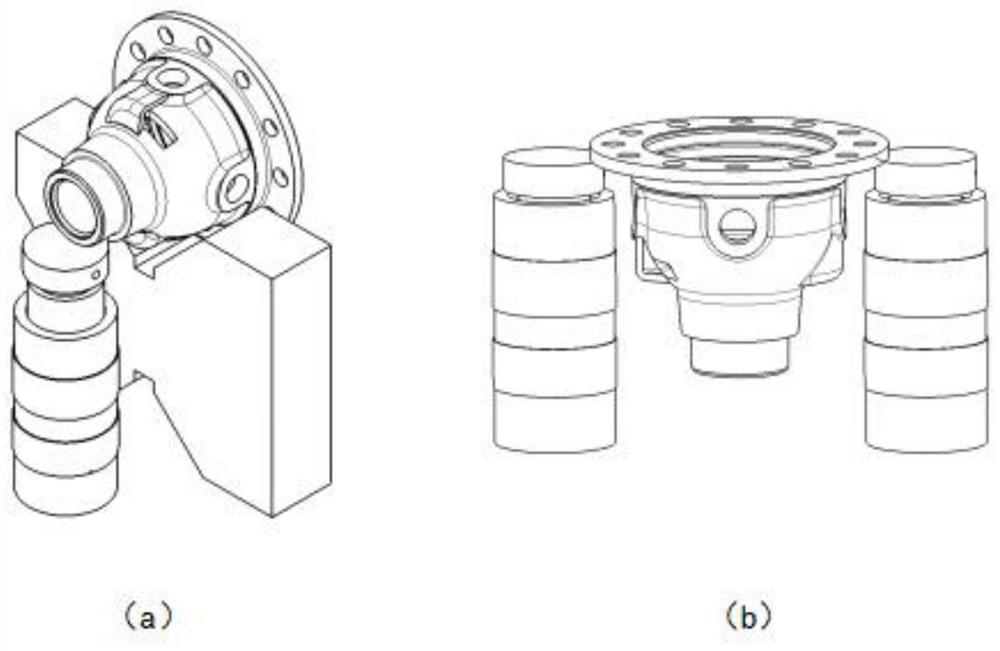

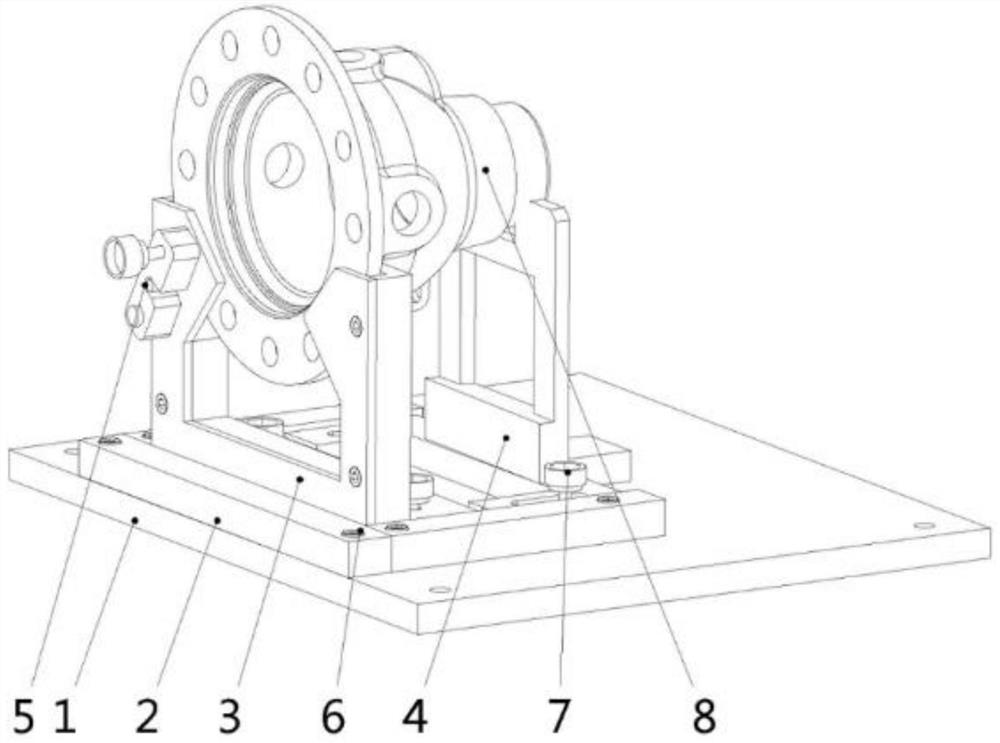

[0021] see Figure 2-Figure 7 , the present embodiment provides an auxiliary tool for detecting the differential housing, including a base 1, a U-shaped positioning block assembly 2, a front V-shaped seat assembly 3, a rear V-shaped seat assembly 4, and an angular device assembly 5. Positioning bolts 6 and fastening bolts 7; the base 1 is fixed on the three-coordinate detection table, the U-shaped positioning block assembly 2 is fixed on the base 1 through the positioning bolts 6, the front V-shaped seat assembly 3 and the rear The V-shaped seat assembly 4 is fixed on the base 1 by fastening bolts 7, and is located in the U-shaped positioning block assembly 2. The angular device assembly 5 is installed on the front V-shaped seat assembly 3. The front V-shaped seat assembly Install the differential case 8 on the 3 and the rear V-shaped seat assembly 4.

[0022] The U-shaped positioning block assembly 2 includes a left positioning block, a right positioning block and a front po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com