Low-stress optical cable pay-off device

A pay-off device and low-stress technology, which is applied in the field of low-stress optical cable pay-off devices, can solve problems such as pay-off operations and difficult winding reels, and achieve the effects of easy installation, reduced labor intensity, and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

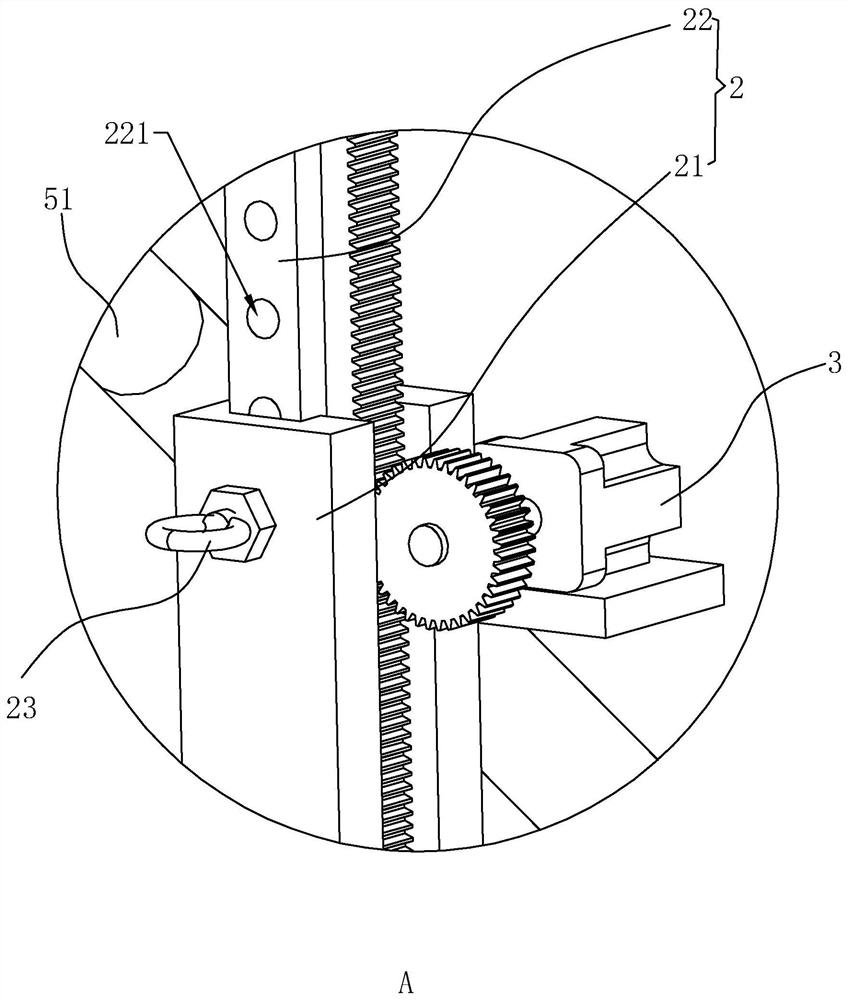

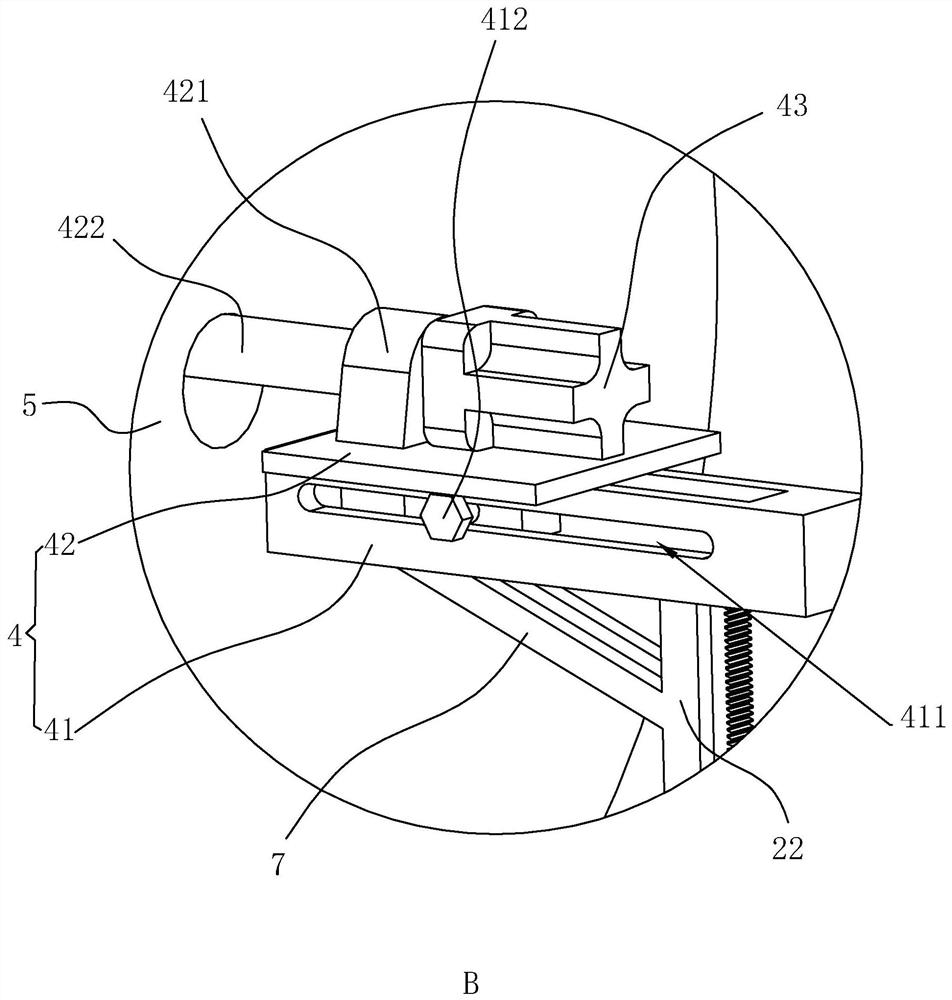

[0032] The following is attached Figure 1-3 The application is described in further detail.

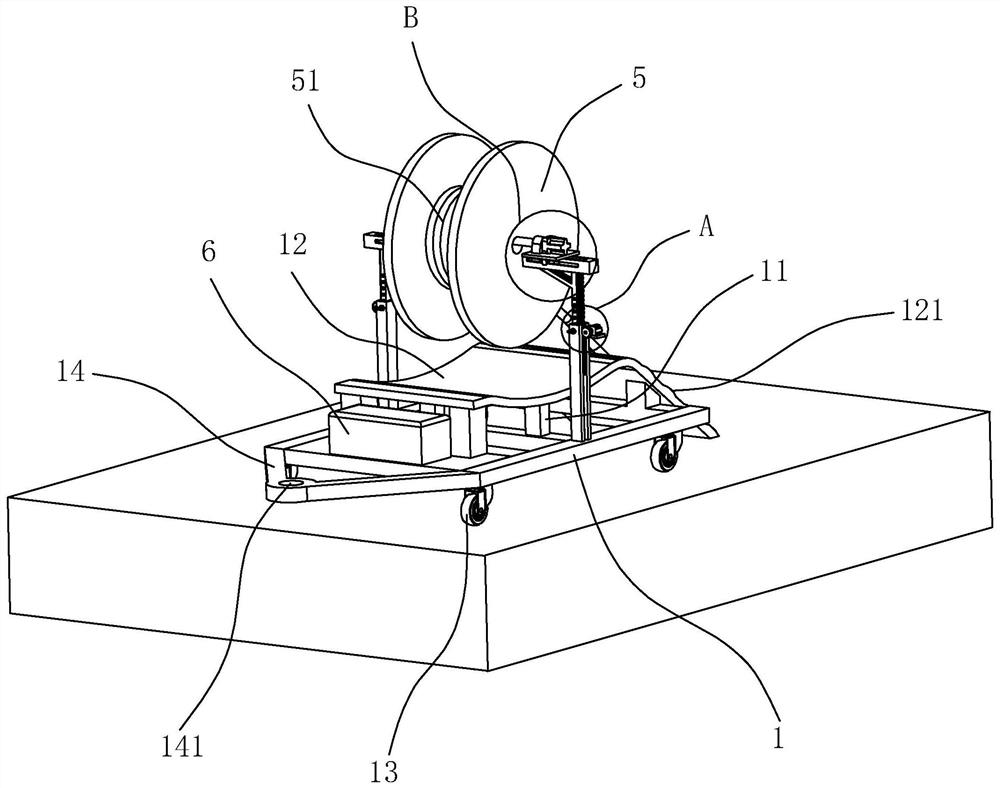

[0033] The embodiment of the present application discloses a low-stress optical cable pay-off device. refer tofigure 1 , the ground is set horizontally, and the low-stress optical cable 51 needs to be laid. During the laying process of the low-stress optical cable 51, the low-stress optical cable 51 is wound up on the reel 5, and before the laying of the low-stress optical cable 51, the strands of the reel 5 are transported to the construction site.

[0034] refer to figure 1 and figure 2 , this kind of low-stress optical cable pay-off device includes a base 1 and two sets of support rods 2, the base 1 is formed by welding several groups of square steel pipes, the base 1 is set horizontally, and the four corners of the lower end surface of the base 1 are all Rotation is connected with universal wheel 13. The front end of the base 1 is integrally fixed with a hanger 14, the plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com