Spiral filtering device for producing melt-blown non-woven fabric special material

A technology of melt-blown non-woven fabrics and filter devices, which is applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., which can solve the problems of multiple impurities, melt solidification, and melt residues, and reduce residual impurities , It is not easy to solidify, and the effect of improving the filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

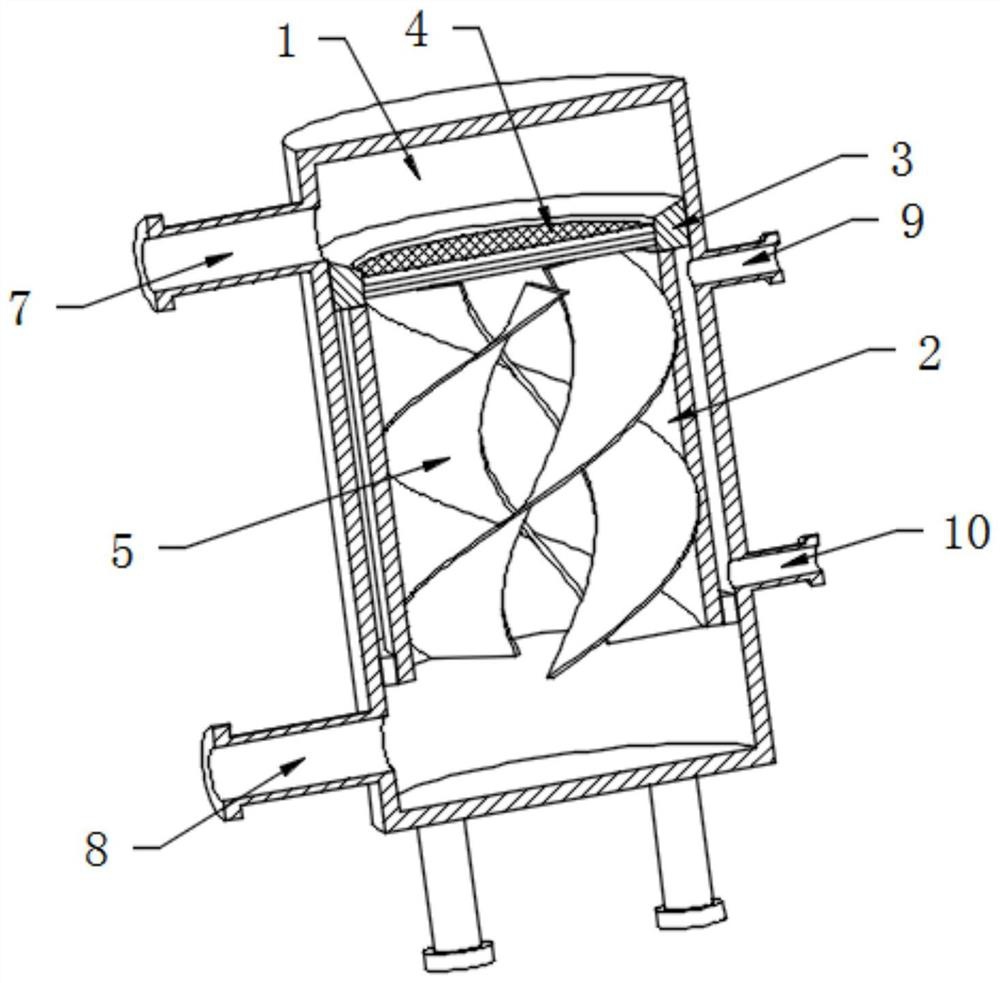

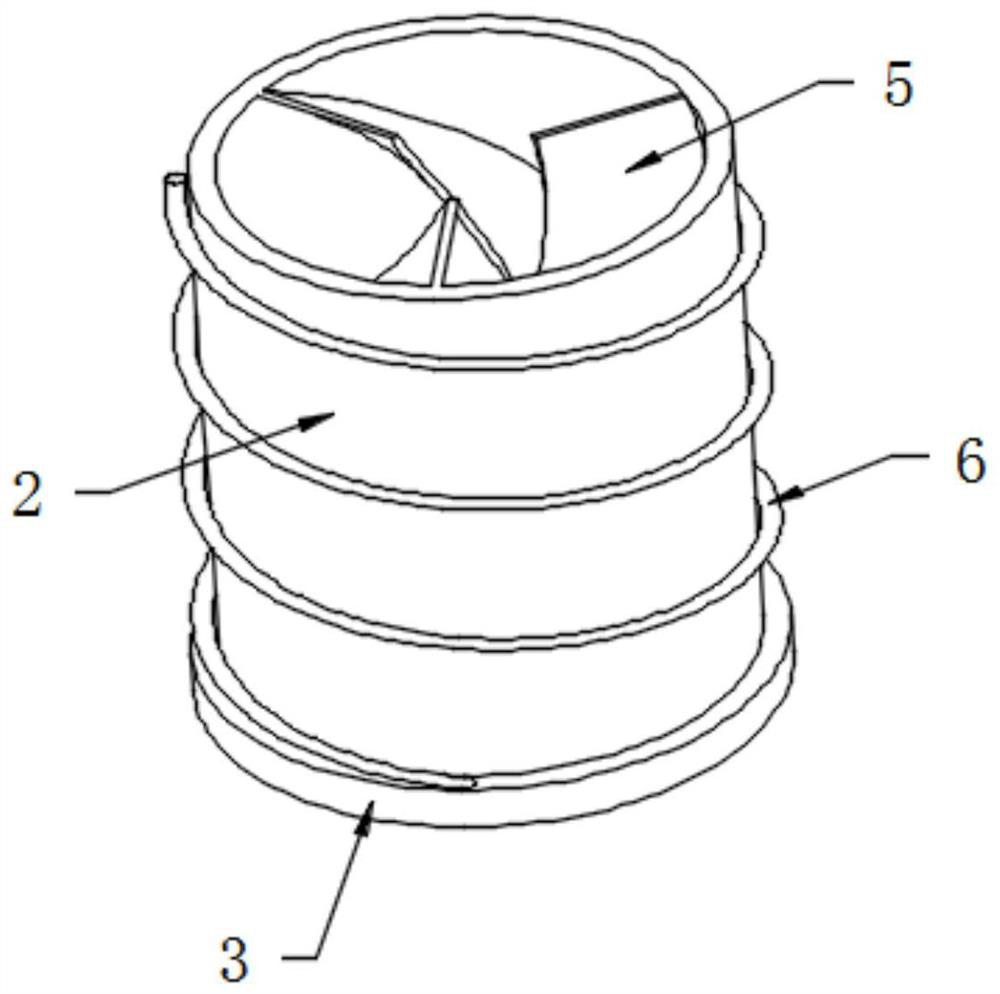

[0038] see Figure 1-2 , a spiral filter device for the production of special materials for melt-blown non-woven fabrics, including a housing 1 and a cylinder 2 arranged inside the housing 1, and also includes: a filter part, which is arranged inside the cylinder 2 for melt Filtration and impurity removal; heat preservation part, the heat preservation part is set on the outside of the cylinder 2 for heating the melt.

[0039] The filter part includes: a fixed ring 3, two fixed rings 3 are provided, and the two fixed rings 3 are fixedly arranged on both axial sides of the cylinder body 2; a filter screen 4, the filter screen 4 is arranged on the upper end of the cylinder body 2, And fixedly connected with the fixed ring 3; filter plate 5, at least two filter plates 5 are provided, and the filter plate 5 is fixedly arranged on the inner surface wall of the cylinder body 2;

[0040] The filter screen 4 is composed of at least two fine-mesh metal screens stacked, the filter plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com