Permanent-magnet direct-drive system for cooling tower

A permanent magnet direct drive and cooling tower technology, applied in the field of cooling towers, can solve problems such as easy wear, loss of rotation, loss of transmission efficiency, etc., and achieve the effects of improving transmission efficiency, reducing mechanical loss, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

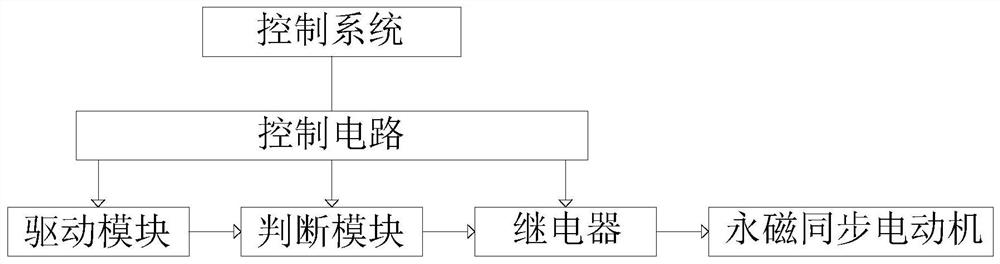

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

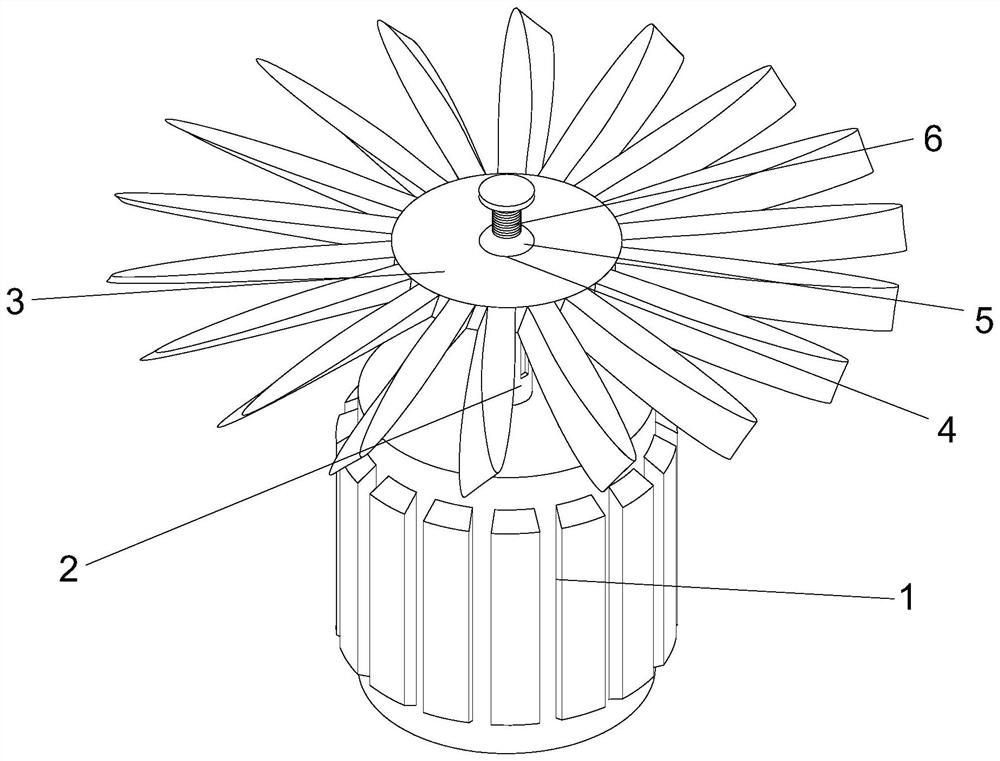

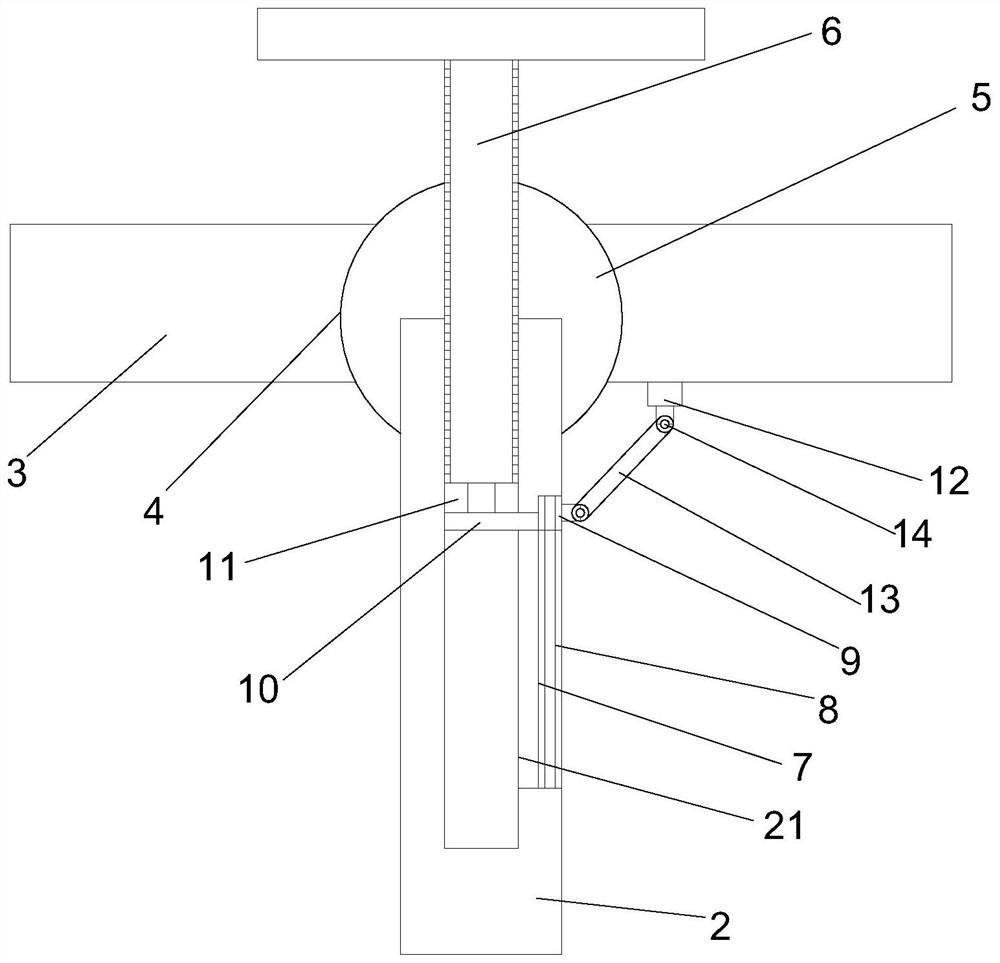

[0029] Embodiment: a kind of permanent magnet direct drive motor for cooling tower, such as Figure 1-Figure 2 As shown, it includes a permanent magnet synchronous motor 1 and an impeller 3, the output end of the permanent magnet synchronous motor 1 is fixedly installed with a transmission shaft 2, the top wall of the transmission shaft 2 is provided with a thread groove 21, and the impeller 3 is arranged on the permanent magnet synchronous motor 1, the top wall of the impeller 3 is provided with an adjustment groove 4, the inner side wall of the adjustment groove 4 is arc-shaped, and the inside of the adjustment groove 4 is slidingly connected with a spherical adjustment ball 5, which facilitates the impeller 3 to rotate up and down , the top of the side wall of the adjustment groove 4 is threadedly connected with a threaded rod 6, and the bottom end of the threaded rod 6 passes through the inside of the adjusting ball 5 and is threadedly connected with the inner side wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com