Micro permanent magnet motor for liquid cooling pump

A technology for permanent magnet motors and pumps, used in magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of insufficient structural strength, weak radial impact resistance, unreasonable flow channel settings, etc., to avoid relative rotational motion. , the effect of reducing volume and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further elaborated and described below in conjunction with the accompanying drawings and specific embodiments.

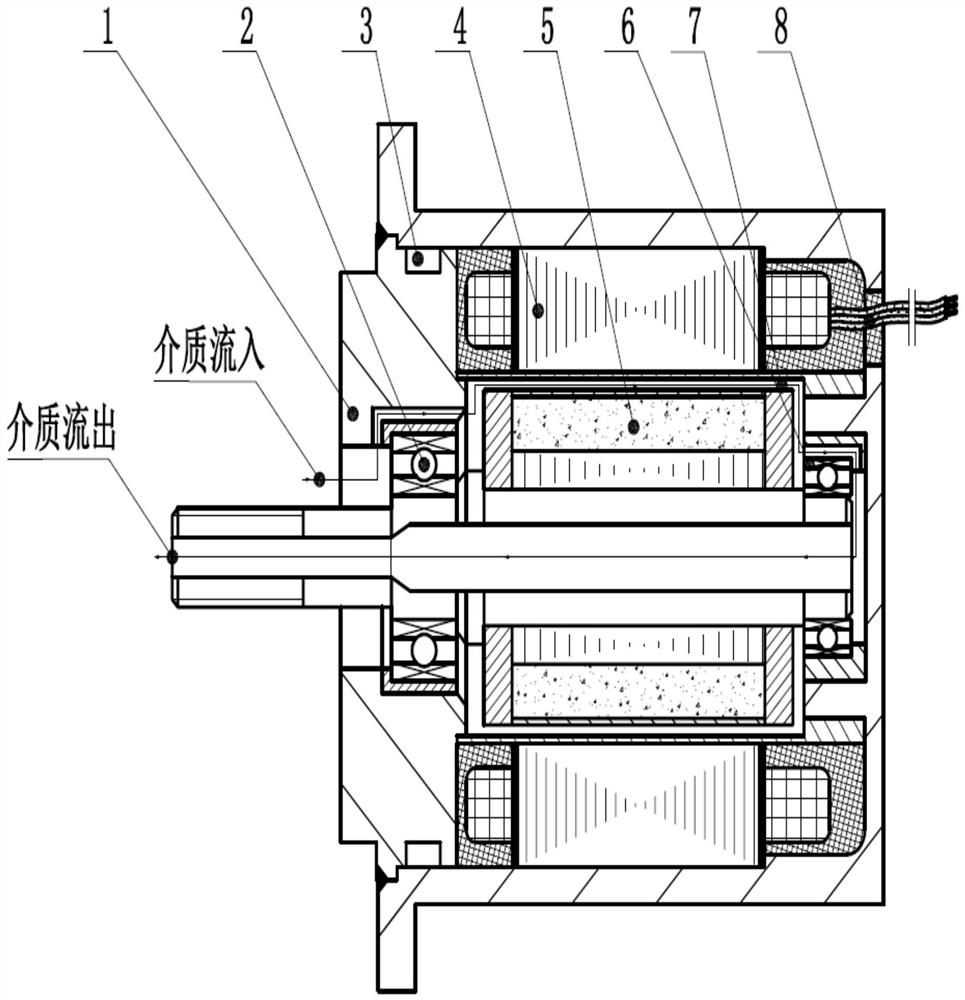

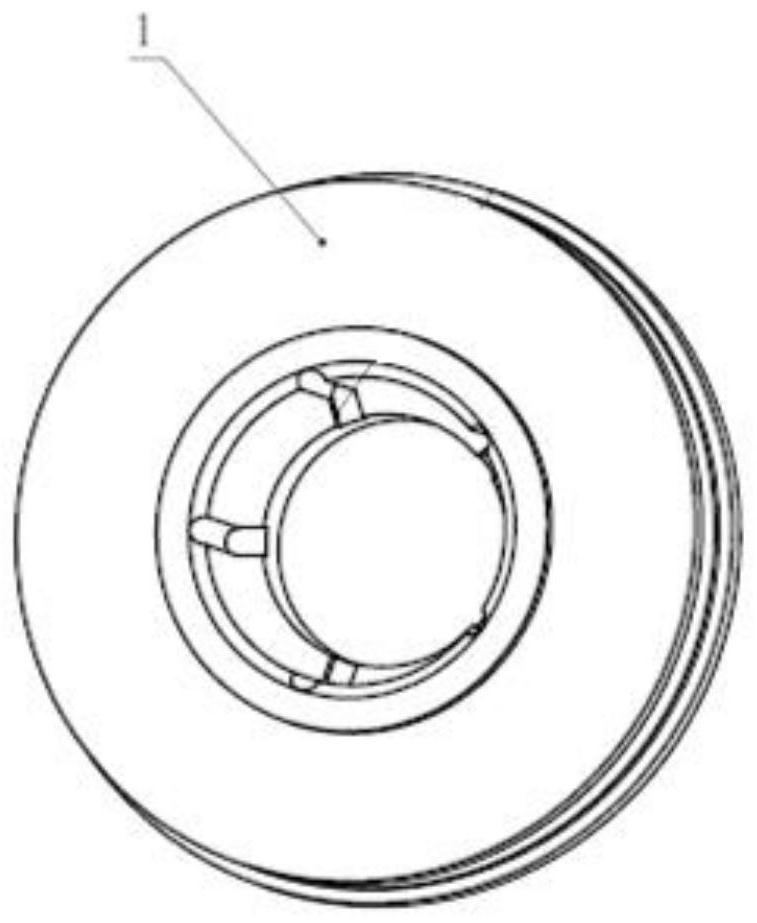

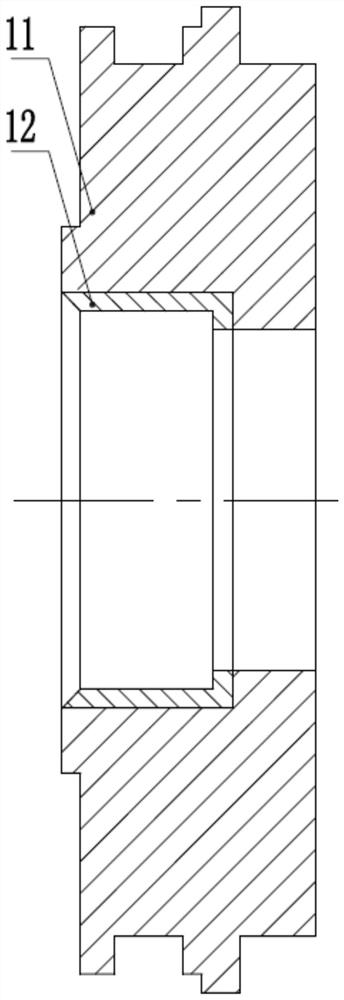

[0055] The present invention relates to a micro permanent magnet motor for a liquid-cooled pump. The outer diameter of the motor is 8 mm, the motor efficiency can reach 95%, and the rated speed of the motor is 16000 r / min. like figure 1As shown: the motor includes an end cover assembly 1, a casing 45, a stator assembly 4 and a rotor assembly 5. After the end cover assembly 1 and the casing 45 are fixed and sealed, a stator and rotor assembly cavity for the stator assembly 4 and the rotor assembly 5 is formed. In the stator-rotor installation cavity, the rotor assembly 5 is connected to the end cover assembly 1 through the front bearing 2, the rotor assembly 5 is connected to the stator assembly 4 through the rear bearing 6, the rear bearing 6 is located at the tail of the casing 8, and the stator assembly 4 is located at the casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com