Buckling-restrained damping support hanger

A support hanger and anti-buckling technology, applied in non-rotational vibration suppression, electrical components, etc., can solve problems such as damage to suspended non-structural components, difficult to replace damaged components, damage to seismic connectors, etc., to improve material use efficiency , Avoid overall failure and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

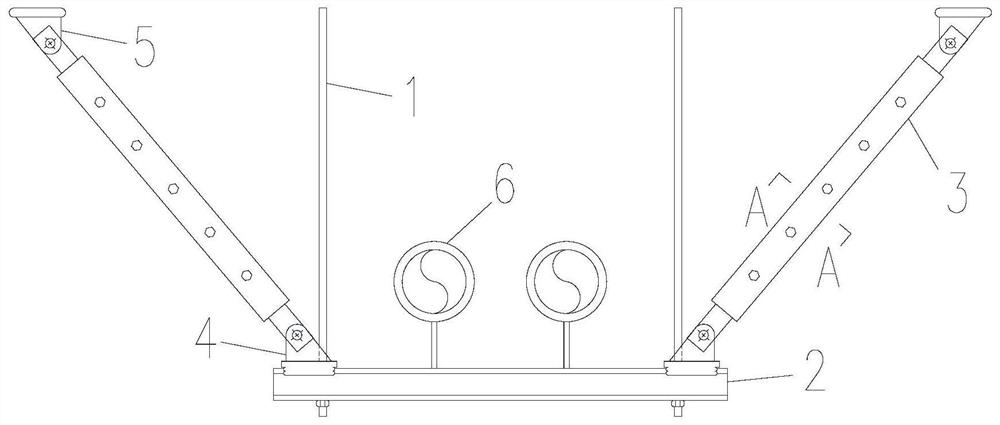

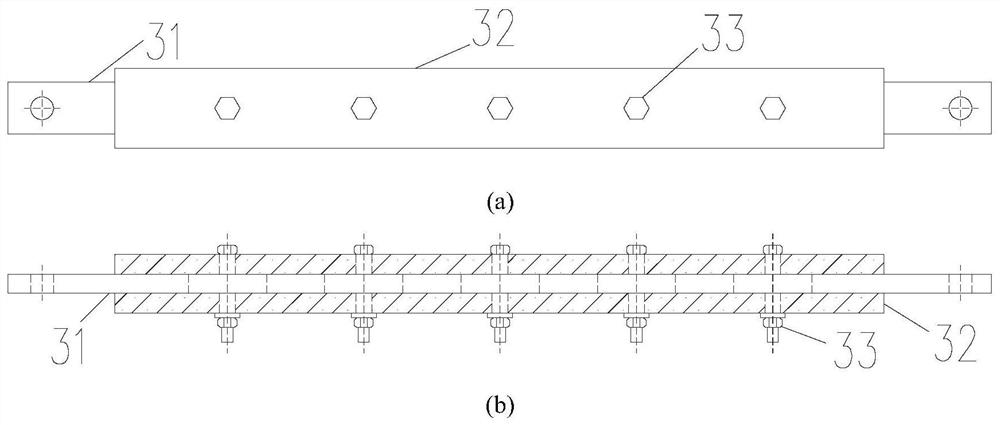

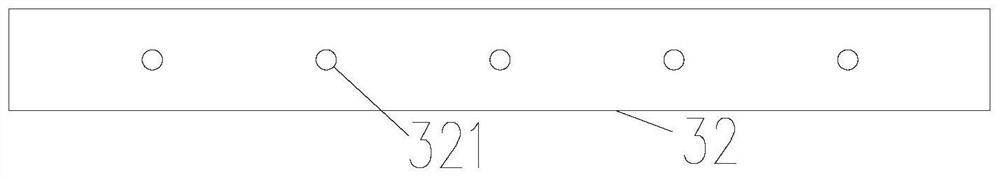

[0038] As shown in the figure, the present invention is an anti-buckling shock-absorbing support and hanger, which mainly includes a load-bearing suspender 1, a load-bearing beam 2, a shock-absorbing support 3, a connecting piece 4, an anchor piece 5, and a pipe fixing piece 6. The anti-buckling shock-absorbing hanger of the present invention is connected to the main structure, and is used to bear the vertical load of the suspended non-structural member, and prevents the entire shock-absorbing hanger from being damaged due to the premature failure of the connecting parts of the shock-absorbing hanger. invalidated.

[0039] Connect the load-bearing suspender 1 and the load-bearing beam 2 through bolts, snap the connector 4 into the load-bearing beam 2 through the buckle 41 and fix it with bolts, use a pin to connect one end of the shock-absorbing support 3 to the connecting plate 41 of the connector 4, Then use the pin to connect the other end of the shock-absorbing support 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com