Anti-seepage, anti-deformation and anti-explosion keyboard

An anti-deformation, keyboard technology, applied in the direction of instrument, electrical digital data processing, input/output of user/computer interaction, etc., can solve the problems of reducing waterproof effect, heavy overall weight, inconvenient processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

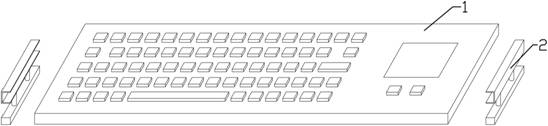

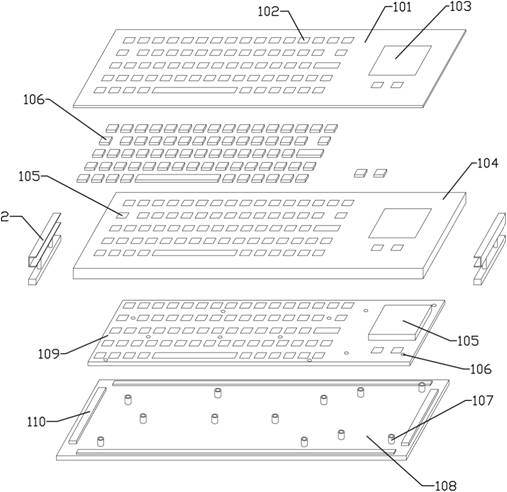

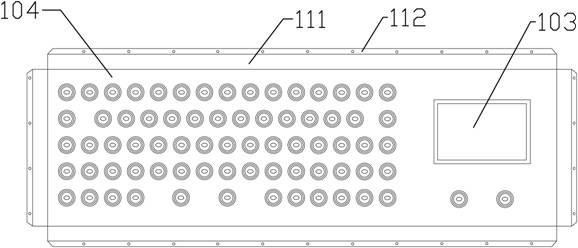

[0032] like Figure 1-11 As shown, an anti-seepage and anti-deformation explosion-proof keyboard includes a keyboard body 1, the keyboard body includes a cover 104, and a cover plate 108 is installed at the opening of the lower end of the cover. Specifically, the cover is made of a stainless steel plate with a thickness of 1.5-2mm or It is made of an aluminum alloy plate with a thickness of 2-2.5 mm, and the cover plate is made of a stainless steel plate with a thickness of 1.5-2 mm or an aluminum alloy plate with a thickness of 2-2.5 mm. In this embodiment, both the casing and the cover plate are made of Made of aluminum alloy with a thickness of 2.5mm and galvanized on the surface, it has high structural strength and good corrosion resistance.

[0033] A surface anti-seepage device is installed outside the case. The surface anti-seepage device includes an anti-seepage film layer 101 installed on the upper end of the case. The anti-seepage film layer is made of PE film with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com