Vertical three-axis simulation rotary table with front yaw axis motor

A technology of yaw axis and motor rotor, which is applied in the direction of weapon accessories, direction control systems, offensive equipment, etc. It can solve the problems of shaft system design that is difficult to meet the requirements, motor torque transmission distance is long, unfavorable high-response indicators, etc. Achieve the effect of realizing the frequency response characteristics of the shafting, improving production efficiency and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

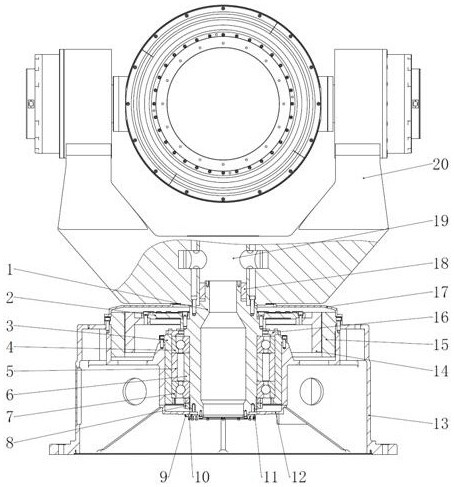

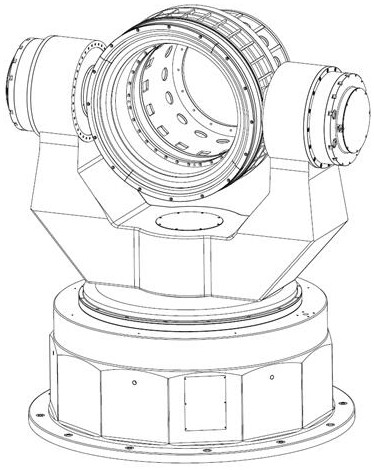

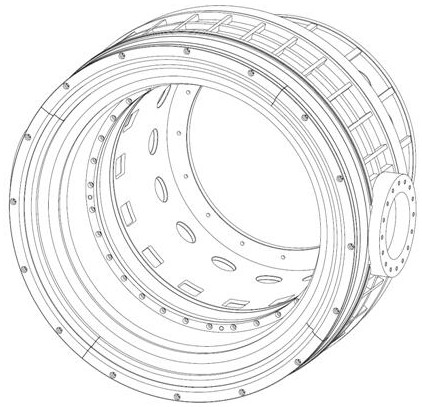

[0028] Such as Figure 1-Figure 7 As shown, a vertical three-axis simulation turntable with a yaw axis motor in front, including a base 13, the base 13 is provided with a main shaft 1, and a bearing assembly is installed on the main shaft 1 through a lock nut 8. The base 13 The upper end is fixed with an outer cover 17, and the upper side of the outer cover 17 is provided with a "U"-shaped frame 20, and the bottom of the "U"-shaped frame 20 is provided with a yaw hole 19, and the lower end of the "U"-shaped frame 20 is sleeved on the On the main shaft 1 , the yaw hole 19 is provided with an expansion sleeve 18 fitted on the main shaft 1 , and the base 13 is located on the upper side of the bearing assembly and provided with a motor fitted on the main shaft 1 .

[0029] The bearing assembly includes a bearing seat 3 fixedly connected to the base 13, a bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com