Temperature control distributed marine pipeline anti-freezing device and laying method thereof

An antifreeze device, distributed technology, applied in pipeline laying and maintenance, pipeline system, mechanical equipment, etc., can solve the problems of high maintenance cost, difficult operation, low intelligence, etc., to improve the antifreeze and heat preservation function, Realize independent alarm and realize the effect of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

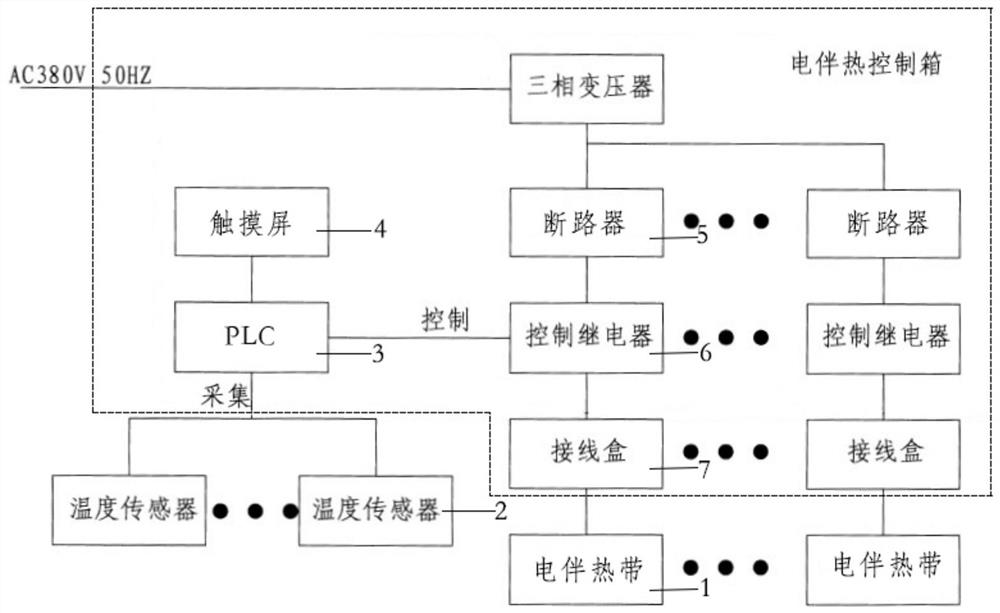

[0027] Below will combine the appended in the embodiment of the present invention figure 1 , to describe in detail the technical solutions, structural features, achieved goals and effects in the embodiments of the present invention.

[0028] It should be noted that in the present invention, relative terms such as first and second are only used to distinguish one entity or operation from another entity or operation, and do not necessarily require or imply that these entities or operations Any such actual relationship or order exists between. Furthermore, the term "comprises", "comprises" or any other variation thereof is intended to cover a non-exclusive inclusion such that a process, method, article, or apparatus comprising a set of elements includes not only the elements explicitly listed, but also includes none other elements specifically listed, or also include elements inherent in such a process, method, article, or apparatus.

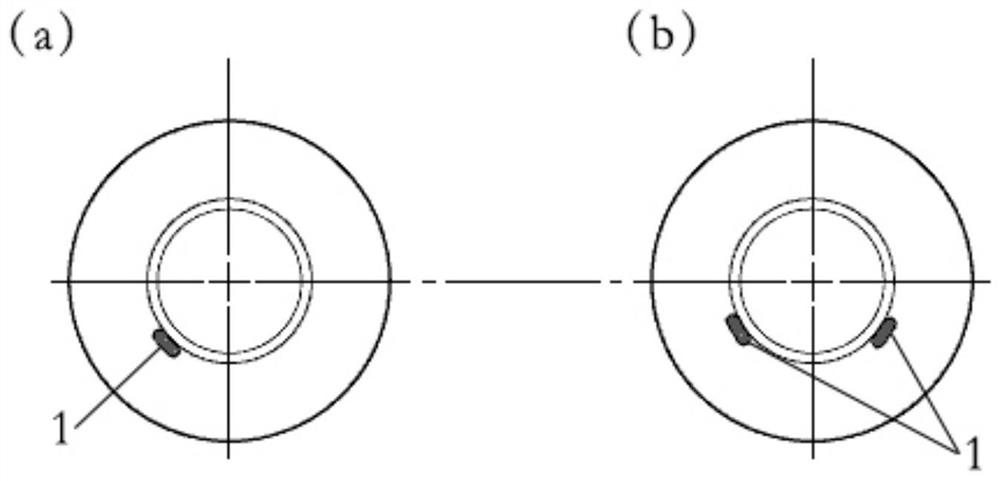

[0029] The invention provides a temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com