Bypass system optimization method for solving unsmooth drainage of deep peak regulation operation heater

A technology of poor drainage and peak-shaving operation, which is applied in the direction of machines/engines, safety devices, mechanical equipment, etc., can solve problems such as large resistance along the way, unreasonable pipeline layout, and improper selection of drainage regulating valves, etc., to achieve improved Efficiency, improving the effect of safe and economical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the accompanying drawings.

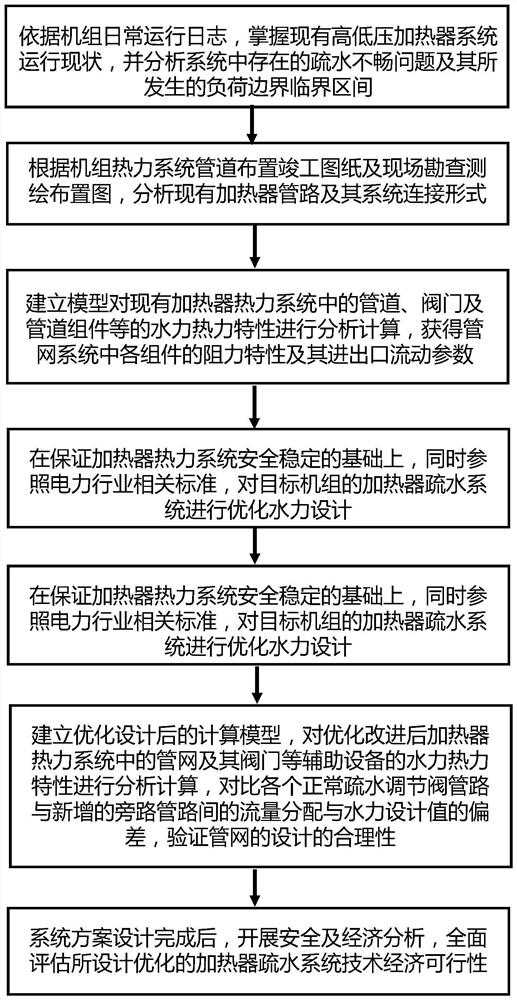

[0069] see figure 1 , the present invention comprises the following steps:

[0070] The present invention comprises the following steps:

[0071] S1, according to the operation log of the unit, obtain the operation status of the heater system, and analyze the load boundary critical interval that occurs when the heater system has poor drainage;

[0072] The operation log of the unit includes the design data of the heater, the current set value of the water level of the heater, the maintenance record of the heater, the content of the maintenance and the emergency repair record, the performance index of the heater under the current rated load condition, the operation log of the unit, the heater occurrence The load boundary with poor drainage and the historical operation data of the steam turbine extraction system and heater system in this state, and the design data incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com