Manufacturing method of stone-like fastening hole decorative sheet and stone-like fastening hole decorative sheet

A production method and technology of decorative sheets, which are applied in the direction of architecture, building structure, floors, etc., can solve the problems of hidden stone-like pattern layers and sheets or boards peeling off, short service life, high material cost, etc., and achieve simple and convenient production methods. The effect of long service life and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

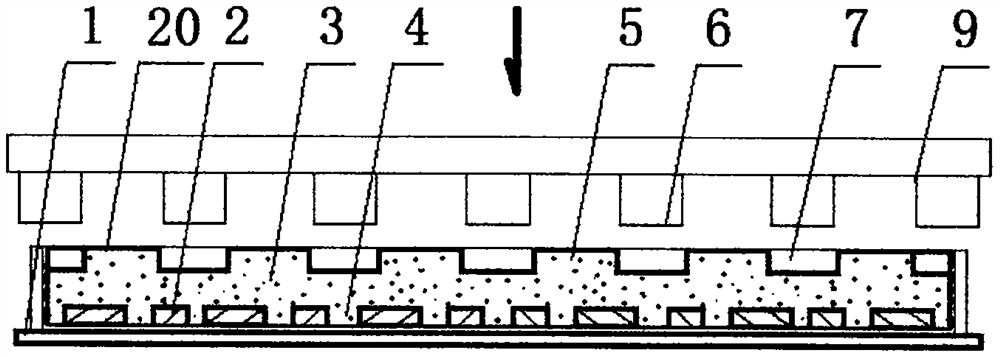

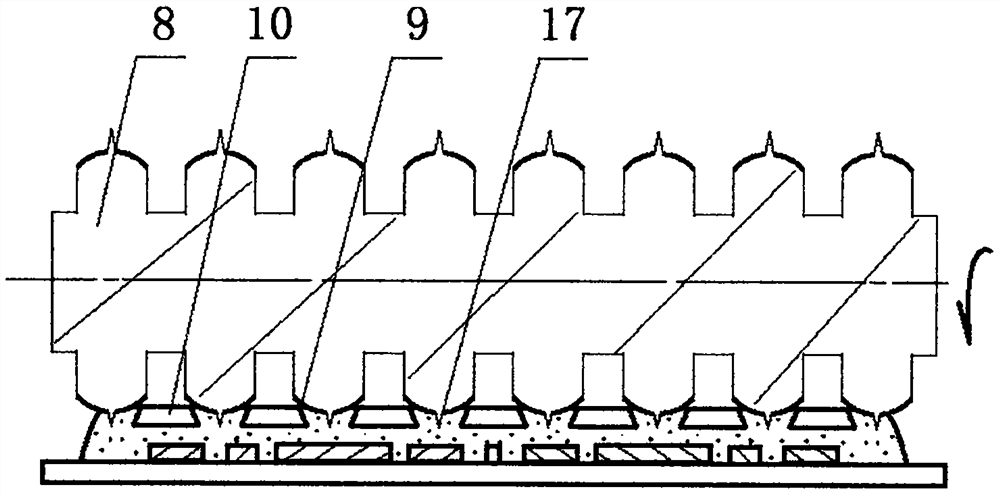

[0037] Embodiment one, according to figure 1 , figure 2 , Figure 7 , Figure 8 Shown:

[0038] A. Distribute fragments (2) of the same color or different colors on the surface of the bottom plate (1) step by step or evenly or unevenly at one time.

[0039] B. On the surface of the bottom plate (1) and / or fragment (2), spread or spray or lay the same color or different colors in batches or at one time. The cement and / or inorganic powder and polymer emulsion, silica fume, A stone-like mixed slurry (3) composed of one or more of pigments, sand, rock flakes, floating beads, microbeads, fibers, and additives, so that the stone-like mixed slurry (3) forms a solid surface on the side of the debris (2) The ground is embedded and bonded together with the side and upper surface of the fragment (2), and the fragment (2) and the imitation stone mixed slurry (3) jointly form the imitation stone layer (4).

[0040] C. Smooth the upper surface of the imitation stone mixed slurry (3) t...

Embodiment 2

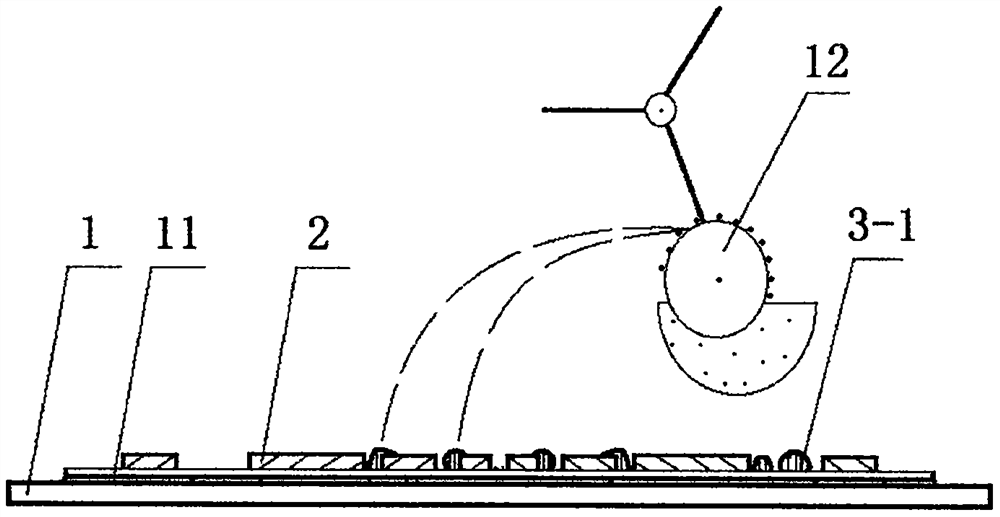

[0043] Embodiment two, according to image 3 , Figure 4 , combined with Figure 9 Shown:

[0044] A. One or more of cement or / and inorganic powder and polymer emulsion, pigment, sand, floating beads, micro-beads, fibers, and additives are mixed with an appropriate amount of water to form a mixed slurry, and then the mixed slurry is rolled Dip or roll or spray or spread or extrude to make a sheet with a thickness of 0.5 mm to 3 mm, and then break into pieces with a diameter of 1.5 mm to 13 mm after the sheet is dry or has a suitable strength (2);

[0045] B. Spray 0.1mm~0.3mm adhesive layer (11) on the surface of the base plate (1), and place fragments (2) on the surface of the adhesive layer (11), so that the lower surface of the fragments (2) is pasted on the surface of the adhesive layer (11) .

[0046] C. Through the spreading device (12), the imitation stone mixed slurry (3-1) of the same color or different color as the fragment (2) is divided into regular or irregular ...

Embodiment 3

[0050] Embodiment three, according to Figure 5 , combined with Figure 9 Shown: After the fragments (2) are laid out, the dried transparent or translucent mixed with fragments (2) or / and flocculation, silk (15) or / A synergistic mixed slurry (16) with glass sand or / and glass beads or / and aluminum hydroxide; the synergistic mixed slurry (16) is 0.3 mm to 3 mm thick after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com