High-quality olive oil processing technology

A processing technology, olive oil technology, applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of intolerance to storage, high chemical residues of solvents, high olive residue, avoid high temperature treatment, and retain nutrients. The effect of value, long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

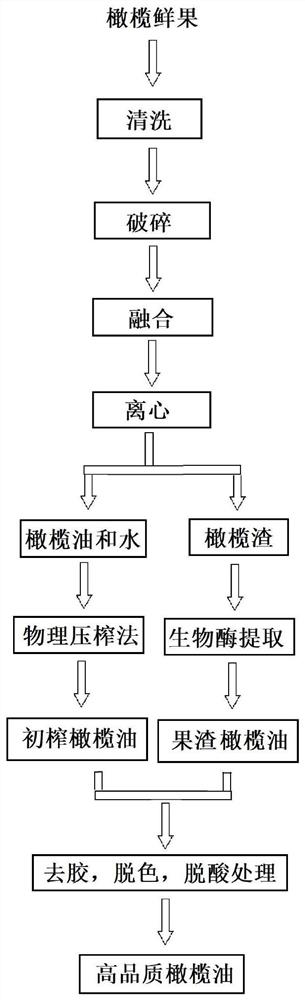

[0034] A high quality olive oil processing process such as figure 2 shown, including the following steps:

[0035] S1. Remove the branches and leaves of the fresh olive fruit after picking, wash and dry, then crush to remove the shell, and then crush the fresh olive fruit with a crusher at a crushing speed of 2500r / min, and filter the olive paste obtained after crushing Processing, the diameter of filter sieve hole is 5mm, obtains olive paste; Olive fresh fruit comprises green fruit and black fruit, and the mass ratio of green fruit and black fruit is 5:1;

[0036] S2. Transfer the olive paste obtained in step S1 to the fusion tank and stir and mix for 30 minutes, and control the temperature in the fusion tank to be less than 40°C;

[0037] S3. Put the olive paste after fusion treatment in step S2 into a closed centrifuge for centrifugation for 15 minutes, the centrifugal speed is 30r / min, the pressure in the closed centrifuge is 0.5MPa, and the temperature is 42°C, then tak...

Embodiment 2

[0045] A high quality olive oil processing process such as figure 2 shown, including the following steps:

[0046] S1. Remove the branches and leaves of the fresh olive fruit after picking, wash and dry, then crush to remove the shell, and then crush the fresh olive fruit with a crusher at a crushing speed of 3000r / min, and filter the olive paste obtained after crushing Processing, the diameter of filtering sieve hole is 5mm, obtains olive paste; Olive fresh fruit comprises green fruit and black fruit, and the mass ratio of green fruit and black fruit is 4:1;

[0047] S2. Transfer the olive paste obtained in step S1 to the fusion tank and stir and mix for 20 minutes, and control the temperature in the fusion tank to be less than 40°C;

[0048] S3. Put the olive paste after fusion treatment in step S2 into a closed centrifuge for centrifugation for 10 minutes, the centrifugal speed is 40r / min, the pressure in the closed centrifuge is 0.4MPa, the temperature is 45°C, and then ...

Embodiment 3

[0056] A high quality olive oil processing process such as figure 2 shown, including the following steps:

[0057] S1. Remove the branches and leaves of the fresh olive fruit after picking, wash and dry, then crush to remove the shell, and then crush the fresh olive fruit with a crusher at a crushing speed of 2800r / min, and filter the olive paste obtained after crushing Processing, the diameter of filtering sieve hole is 6mm, obtains olive paste; Olive fresh fruit comprises green fruit and black fruit, and the mass ratio of green fruit and black fruit is 3:1;

[0058] S2. Transfer the olive paste obtained in step S1 to the fusion tank and stir and mix for 30 minutes, and control the temperature in the fusion tank to be less than 40°C;

[0059] S3. Put the olive paste after fusion treatment in step S2 into a closed centrifuge for centrifugation for 15 minutes, the centrifugal speed is 30r / min, the pressure in the closed centrifuge is 0.4MPa, and the temperature is 40°C, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peroxide value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com