Spherical-like super-macroporous mesoporous material, polyolefin catalyst, preparation methods thereof and olefin polymerization method

A polyolefin catalyst and mesoporous material technology, applied in the field of olefin polymerization, to achieve the effect of reducing agglomeration, narrow distribution and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

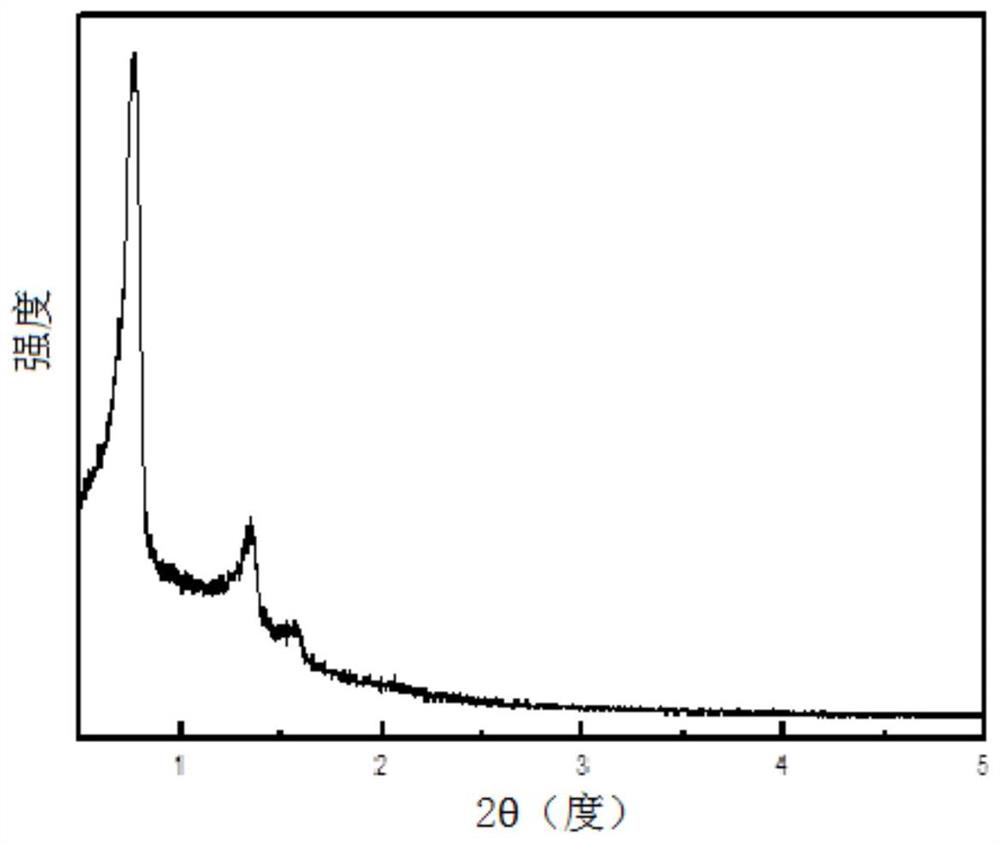

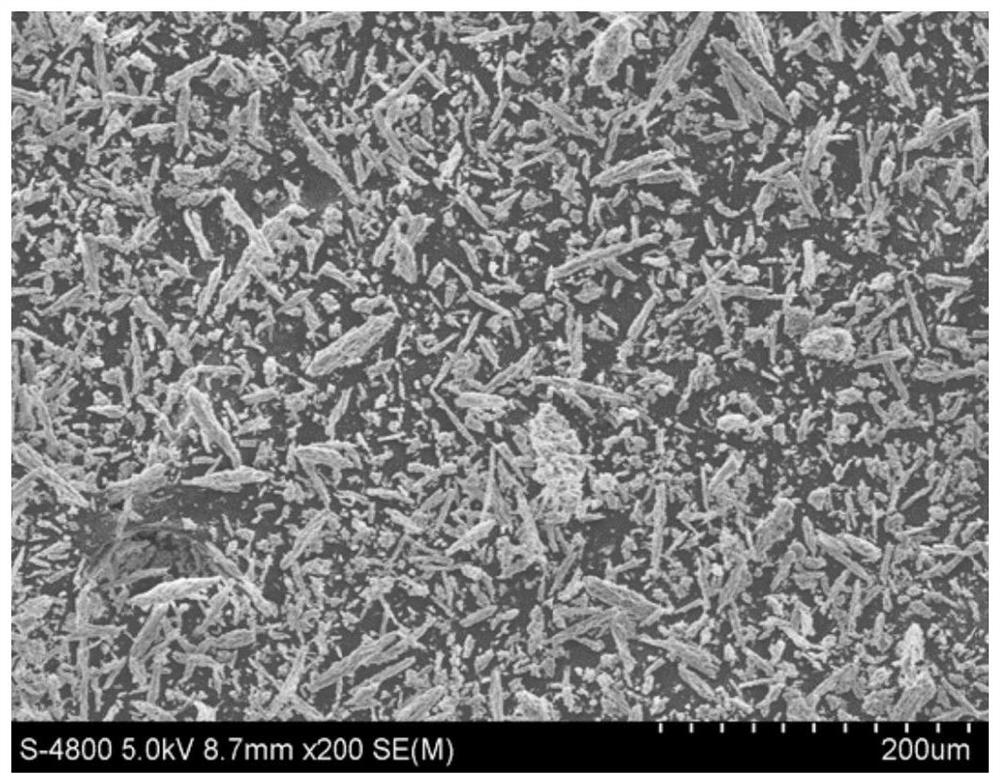

[0054] The second aspect of the present invention provides a method for preparing a spherical mesoporous material, characterized in that the method comprises the following steps:

[0055] (1) In the presence of templating agent and water, silicon source, acid agent, ammonium fluoride and heptane are mixed and contacted, and the mixture obtained after mixing and contacting is successively crystallized, filtered and dried to obtain spherical media Raw powder of porous material;

[0056] (2) The raw powder of the quasi-spherical mesoporous material is sequentially subjected to template release agent treatment, primary thermal activation treatment and secondary thermal activation treatment.

[0057] In the present invention, in step (1), the mixing and contacting method includes: stirring at a temperature of 25° C. to 60° C. for more than 4 minutes, and then standing still for more than 1 hour. In order to be more conducive to the uniform mixing of various substances, according t...

Example Embodiment

[0075] According to a preferred embodiment of the present invention, the method further includes: mixing and stirring the product obtained from the thermal activation treatment with the chlorosilane.

[0076] In the present invention, by mixing and stirring the product obtained by thermal activation treatment with chlorosilane, the modification of mesoporous material by chlorosilane is realized, so that the prepared spherical super-macroporous mesoporous material has the characteristics of lipophilicity, thereby Further ensure that the mesoporous material is in a state of low moisture content and oxygen content for a long time.

[0077] According to the present invention, the chlorosilane refers to various substances containing carbon, chlorine and silicon, containing or not containing oxygen atoms, and not containing hydrophilic groups such as hydroxyl, amino and carboxyl groups, which may contain one or A plurality of chlorine atoms, one or more silicon atoms, and multiple c...

Example Embodiment

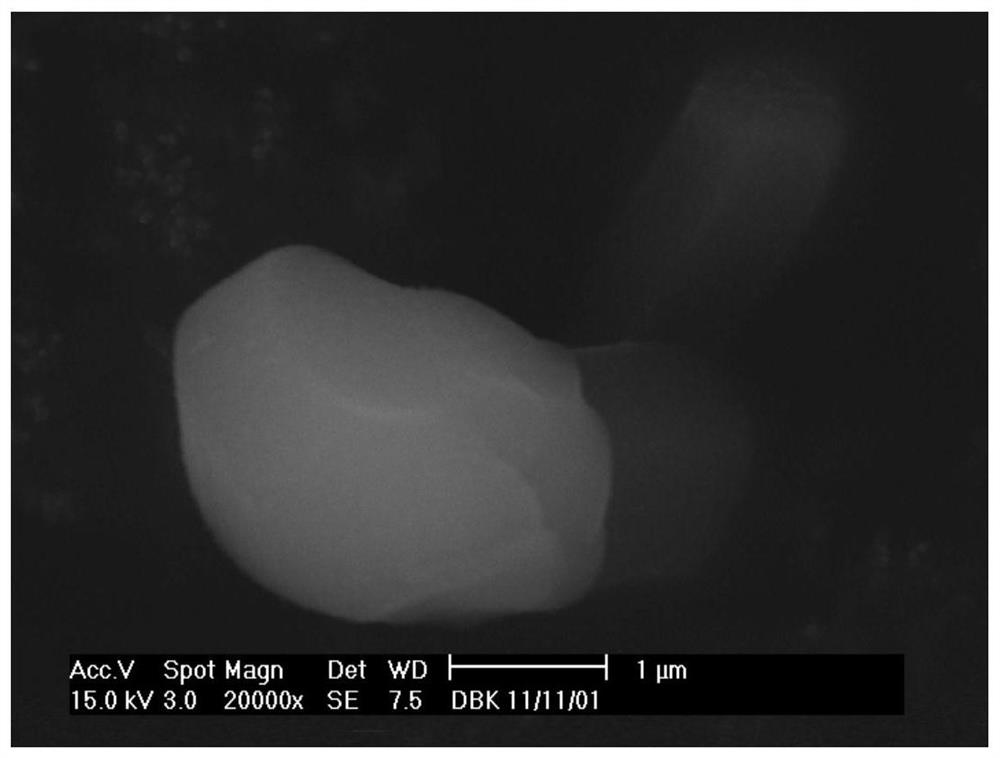

[0141] Example 1

[0142] This example is used to illustrate the polyolefin catalyst component and its preparation method.

[0143] (I) Preparation of carrier

[0144] (1) 2.4 grams of P123 (the registration number in American Chemical Abstracts is 9003-11-6, its average molecular weight Mn=5800) and 0.028 grams of ammonium fluoride are added to 80 mL of hydrochloric acid solution with a concentration of 1.75 mol / L , stirred at 20°C until P123 and ammonium fluoride were completely co-dissolved;

[0145] (2) Add 17mL of n-heptane and 5.5mL of ethyl orthosilicate to the above solution, stir vigorously at 20°C for 4 minutes and then let stand for 1 hour;

[0146] (3) Transfer the obtained solution to a polytetrafluoroethylene-lined reaction kettle, and crystallize at 100° C. for 24 hours;

[0147] (4) Obtain the former powder mesoporous material after filtering, washing and drying;

[0148] (5) Calcinate the raw powder mesoporous material in a muffle furnace at 500°C for 24 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com