Automatic material placing machine for flexible hot-pressing process

A hot-pressing process and automatic technology, applied in thin material handling, strip winding, transportation and packaging, etc., can solve the problems of cumbersome manual loading and unloading process, low manual operation efficiency, easy operation error FPC, etc. Facilitate transfer and collection, solve multiple labor costs, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

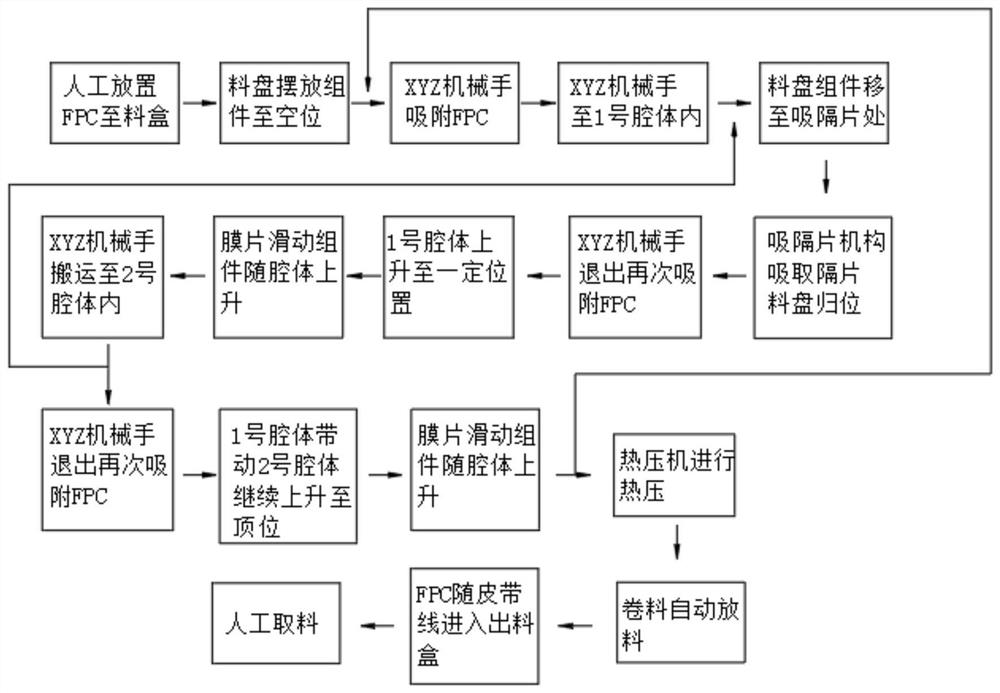

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0029] The embodiments of the present invention will be described below according to the overall structure of the present invention.

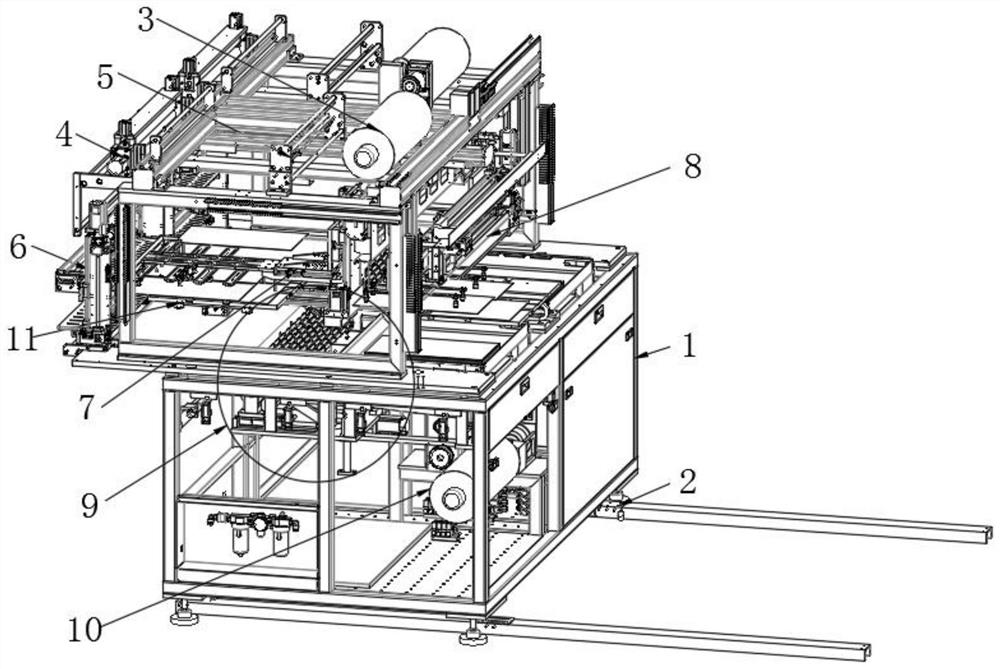

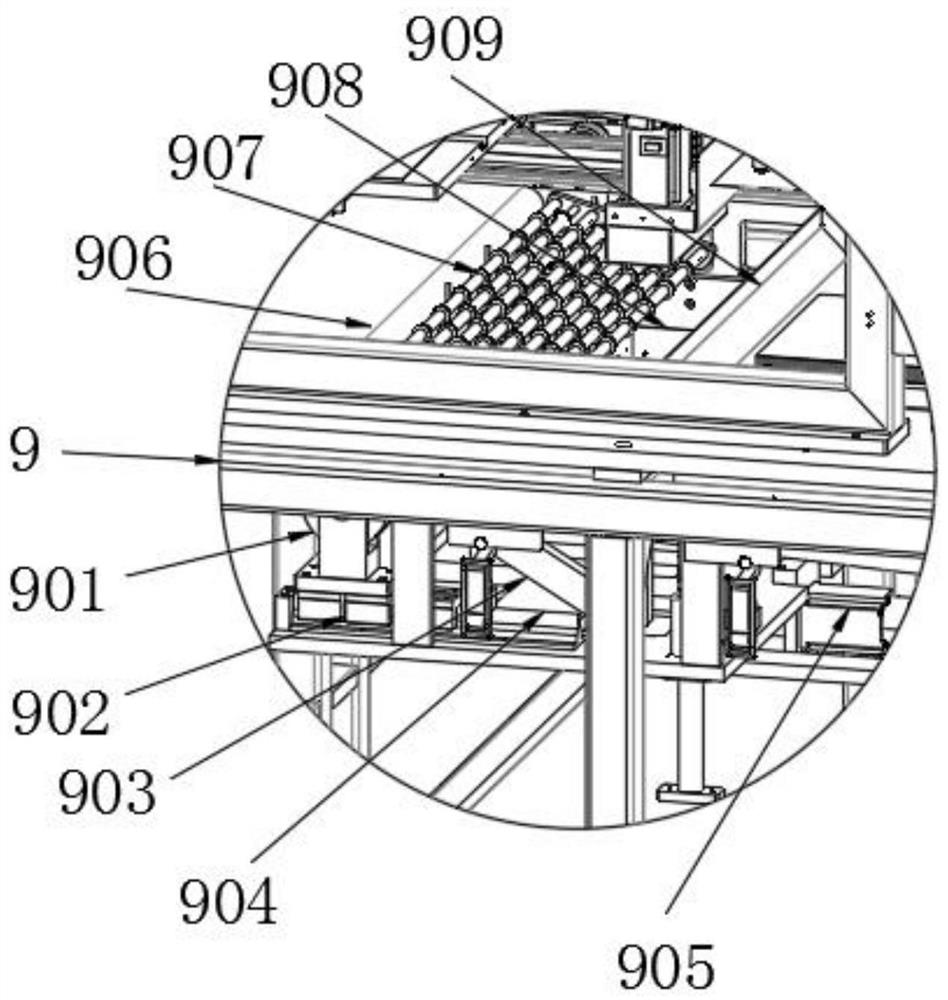

[0030] A kind of automatic material placement machine for flexible hot pressing process, such as Figure 1-2 As shown, it includes the lower shelf 1 docking double-track sliding mechanism 2, the product suction and transportation mechanism 7, the product tray carrying movement mechanism 11, the upper and lower sliding mechanism 6 of the release film, the unwinding mechanism 3, the upper film passing roller mechanism 4, and the winding mechanism. Mechanism 10, multi-po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com