Mixing-type lime kiln capable of quickly cooling and discharging

A lime kiln and mixing technology, applied in the field of lime production, can solve the problems of staff burns, unfavorable collection and transfer, high temperature of finished lime products, etc., and achieve the effect of reducing calcination time, convenient collection, transfer and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

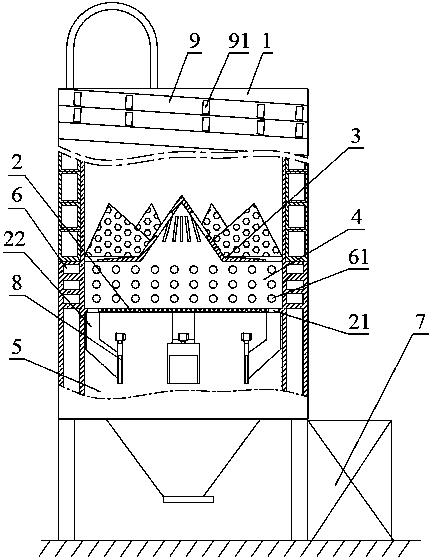

[0024] Such as figure 1 As shown, the mixed-material lime kiln for rapid cooling and discharging includes a kiln body 1, and a partition 2 is arranged inside the kiln body 1, and a plurality of through holes 21 for the passage of lime products are arranged on the partition 2, The dividing plate 2 is arranged on the lower side of the fire grate 3, a cooling chamber 4 is formed between the fire grate 3 and the dividing plate 2, and a collection chamber 5 is formed on the lower side of the dividing plate 2, and the side wall of the cooling chamber 4 is provided with an outlet An air duct 6 , the air outlet duct 6 is connected with an air supply device 7 .

[0025] In the mixing type lime kiln for rapid cooling and discharging of the present embodiment, a partition plate 2 is arranged in the kiln body 1 to form a special cooling chamber 4 between the grate 3 and the collection chamber 5, so that the material falling from the grate 3 The finished lime products entering the cooling...

Embodiment 2

[0028] Such as figure 1 As shown, the rapid cooling and discharging mixing lime kiln of this embodiment has the same structure as that of Embodiment 1, the difference is that the air outlet pipe 6 is laid spirally along the side wall of the cooling chamber 4, and the air outlet pipe 6 is arranged There are several air outlets 61 toward the center of the partition 2 .

[0029] In the mixing type lime kiln for rapid cooling and discharging in this embodiment, the air outlet pipe 6 is spirally arranged along the side wall of the cooling chamber 4, so that the air outlet pipe 6 can cool down the cooling chamber 4 as a whole, and the air introduced into the cooling chamber 4 It can also cool the finished lime product better, and the cooling effect is better. In this embodiment, the cross-section of the air outlet pipe 6 is preferably a rectangular structure. Towards the air outlet 61 at the center of the dividing plate 2, the bottom surface is provided with an air outlet 61 facing...

Embodiment 3

[0031] Such as figure 1 As shown, the rapid cooling and discharging mixing lime kiln of this embodiment has the same structure as that of Embodiment 2, the difference is that a number of feed pipes 22 are arranged at the bottom of the partition plate 2, and the top of the feed pipe 22 is connected to the The through holes 21 are communicated, and the feeding pipe 22 is arranged along the vertical direction of the kiln body 1 .

[0032]In the mixing type lime kiln for rapid cooling and discharging in this embodiment, the finished lime products are temporarily collected by setting the feeding pipe 22 at the bottom of the partition plate 2, so that the finished lime products falling into the cooling chamber 4 enter the feeding pipe 22 for collection in advance, so that The finished lime products are dispersed into a plurality of feeding pipes 22 for cooling respectively, and the cooling effect is more scattered than that accumulated in one collection chamber 5, which makes the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com