Buffering constant-pressure control system of die-cutting machine

A constant pressure control, die-cutting machine technology, applied in metal processing and other directions, can solve the problems of die-cutting force loss, reaction force increase, etc., to achieve smooth operation, eliminate motion inertia, and reduce air pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

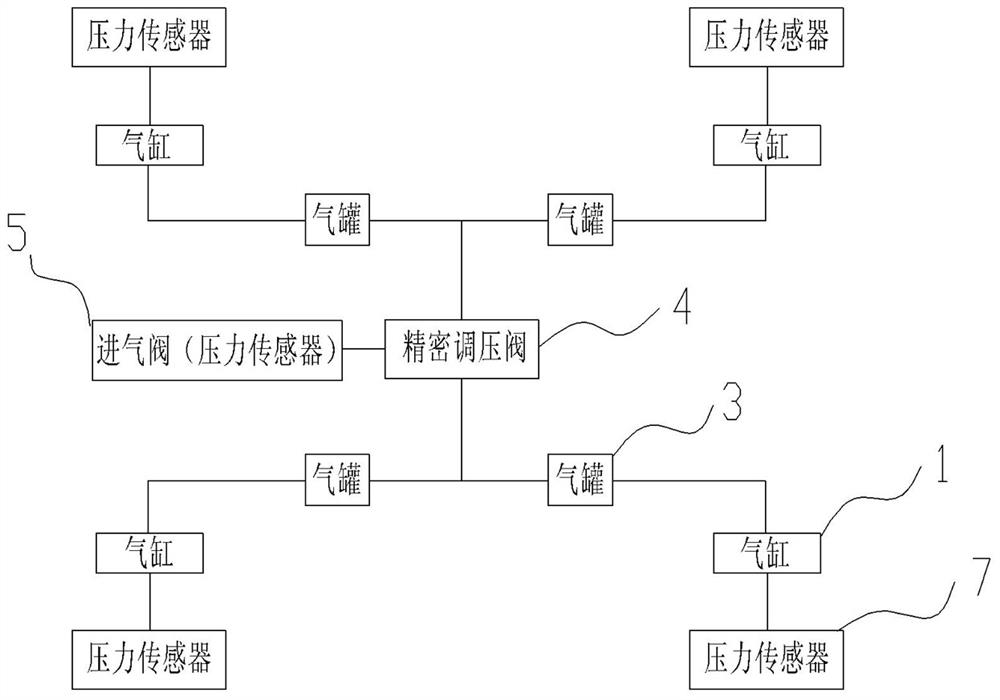

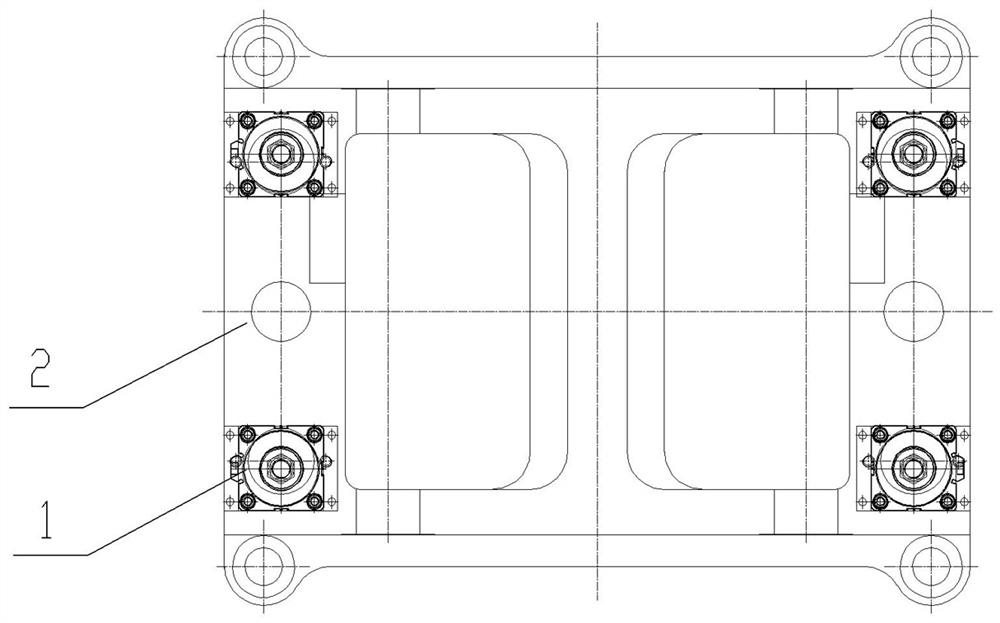

[0013] Accompanying drawing has shown structure of the present invention, further illustrates its relevant details below again in conjunction with accompanying drawing. In this example, see the attached figure 1 , 2 And 3, the buffer constant pressure control system of the die-cutting machine includes a reciprocating cylinder 1, and four reciprocating cylinders 1 are arranged in a square array and fixed on the movable mold 2 of the die-cutting machine, and constitute the movable mold 2 of the die-cutting machine. Buffer structure for the lifting movement of mold 2; four reciprocating cylinders 1 are respectively connected with four buffer gas tanks 3, that is, the gas between cylinder 1 and gas tank 3 is connected, and the air pressure is consistent, which increases the gas storage capacity of cylinder 1. The buffer gas The gas volume of the tank 3 is more than twice the gas volume of the reciprocating cylinder 1, and the four buffer gas tanks 3 are connected to a precision p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com