Eccentric bushing alignment and recovery method based on alignment and recovery assembly

A technology of eccentric bushing and recovery method, which is applied in the field of parts assembly, can solve the problems that the accuracy of bushing replacement cannot be guaranteed, the efficiency of bushing replacement cannot be improved, and the bushing falls off, etc., so as to simplify the restoration and replacement process and structure Simple, anti-shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

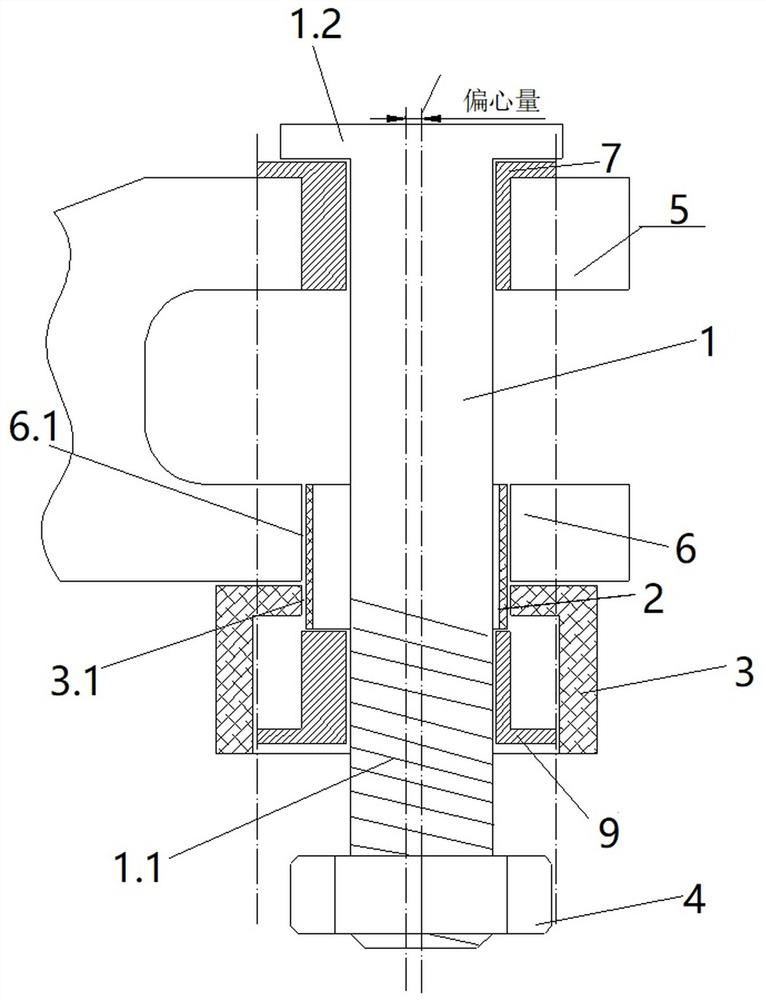

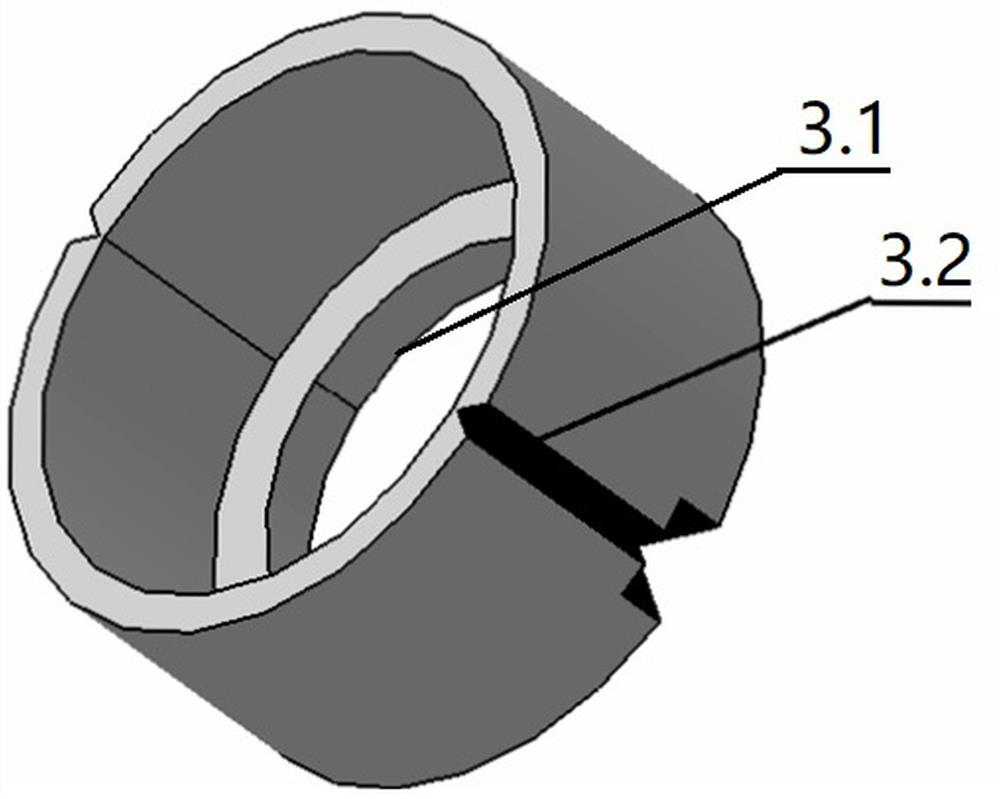

[0037] This embodiment discloses an eccentric bush alignment restoration method based on an alignment restoration assembly. As a basic embodiment of the present invention, the alignment restoration assembly includes a bushing inner hole positioning pin 1, an adapter bushing 2 and Positioning bushing 3, wherein the accuracy of the outer diameter of the positioning pin is not less than h7; the transfer bushing 2 is a hollow cylinder structure with both ends open, and the inner diameter of the transfer bushing 2 is larger than the positioning pin in the inner hole of the bushing 1; the indexing bush 3 is a hollow cylinder structure, and the internal structure of the indexing bushing 3 matches the bushing 9 to be restored; one end of the indexing bush 3 is opened, and the shaft at the other end of the indexing bush 3 A centering hole 3.1 matching the adapter bushing 2 is provided at the center, and at least two cracking grooves 3.2 are provided on the side of the positioning bushin...

Embodiment 2

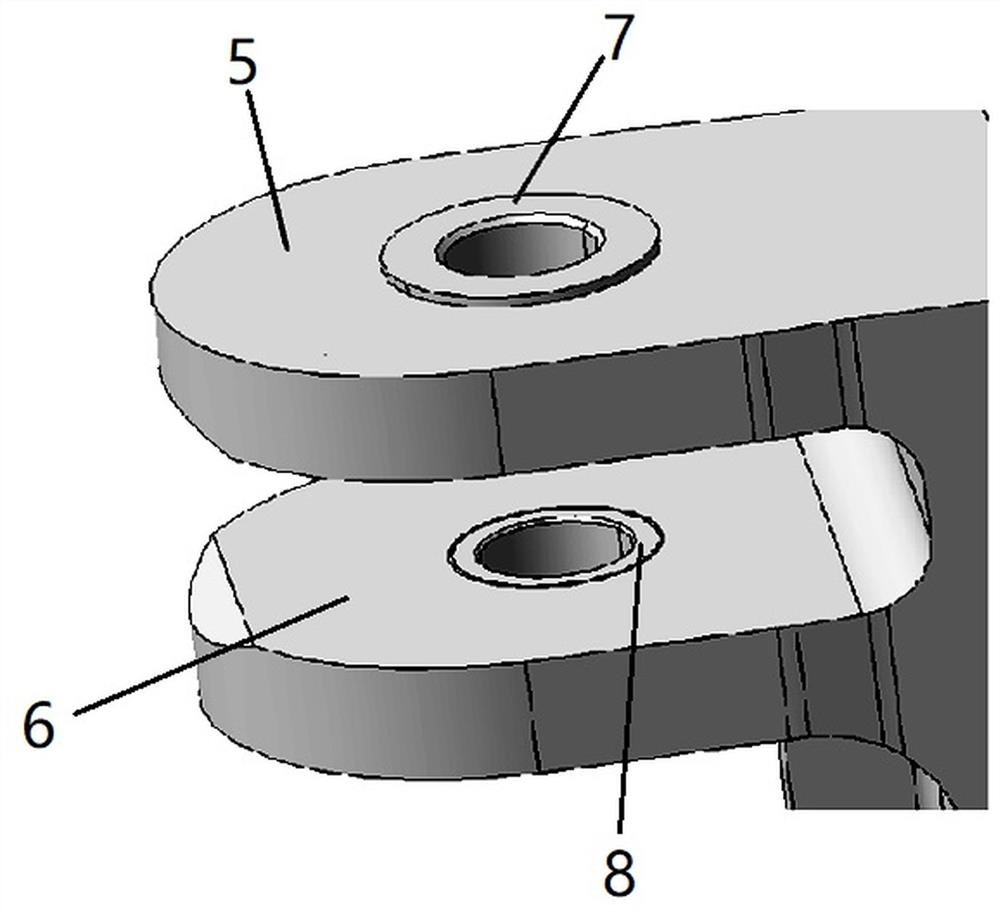

[0051] This embodiment discloses an alignment and recovery method for an eccentric bush based on an alignment restoration assembly. As a basic embodiment of the present invention, the alignment restoration assembly includes a bushing inner hole positioning pin 1, an adapter bushing 2, Positioning bushing 3 and anti-falling nut 4, wherein, the top of the positioning pin 1 in the inner hole of the bushing is provided with a locking structure 1.2, and the end of the positioning pin 1 in the inner hole of the bushing near the bottom is provided with a locking structure for cooperating with the anti-falling nut 4 Thread structure 1.1; the adapter bushing 2 is a hollow cylinder structure with two ends open, and the inner diameter of the adapter bushing 2 is larger than the diameter of the positioning pin 1 in the inner hole of the bushing; the indexing bushing 3 is a hollow cylinder structure , the internal structure of the indexing bush 3 is matched with the bushing 9 to be recovere...

Embodiment 3

[0064] This embodiment discloses an alignment and recovery method for an eccentric bush based on an alignment restoration assembly. As a basic embodiment of the present invention, the alignment restoration assembly includes a bushing inner hole positioning pin 1, an adapter bushing 2, Positioning bushing 3 and anti-falling nut 4, wherein, the top of the positioning pin 1 in the inner hole of the bushing is provided with a locking structure 1.2, and the end of the positioning pin 1 in the inner hole of the bushing near the bottom is provided with a locking structure for cooperating with the anti-falling nut 4 Thread structure 1.1; the adapter bushing 2 is a hollow cylinder structure with two ends open, and the inner diameter of the adapter bushing 2 is larger than the diameter of the positioning pin 1 in the inner hole of the bushing; the indexing bushing 3 is a hollow cylinder structure , the internal structure of the indexing bush 3 is matched with the bushing 9 to be recovere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com