Small milling machine for workpiece positioning

A milling machine, a small-scale technology, applied in the field of milling machines, can solve the problems of low drilling accuracy and efficiency, narrow working space, etc., and achieve the effects of improving production and processing efficiency, high precision, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the present invention more easily to be clearly understood, the following Examples depending on the particular embodiment and the accompanying drawings, the present invention will be further described in detail.

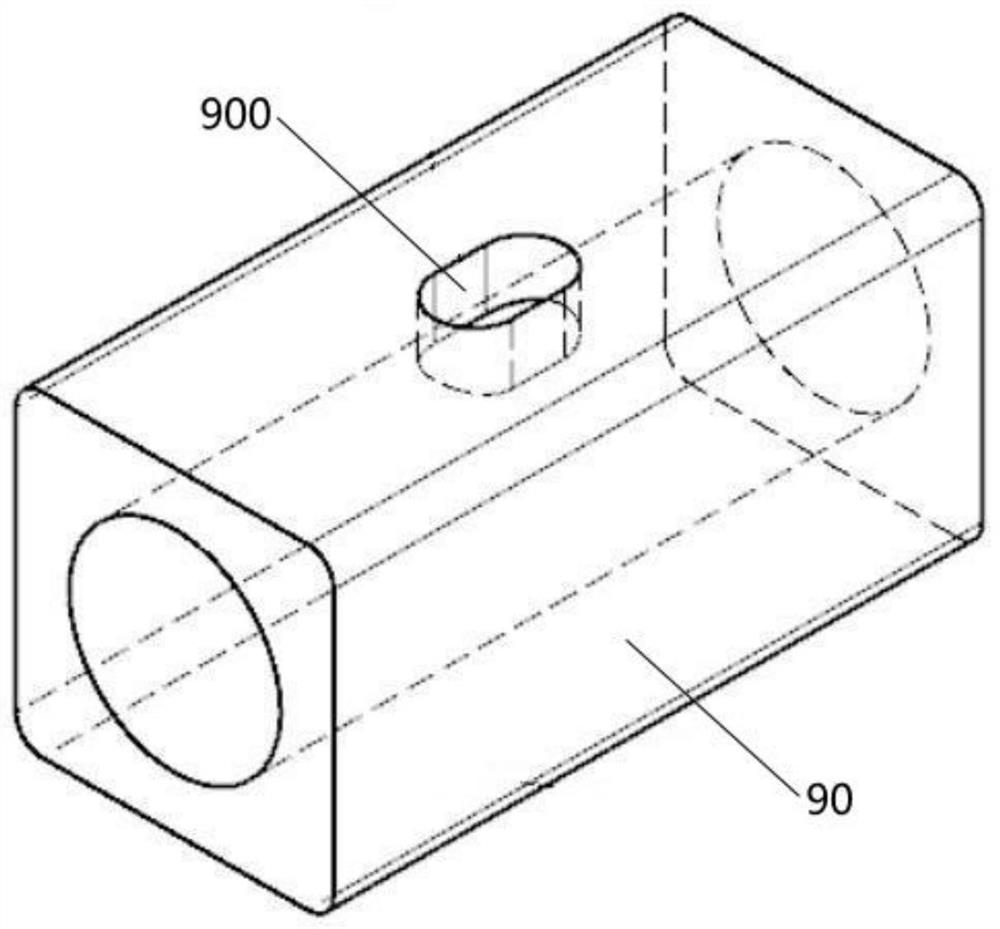

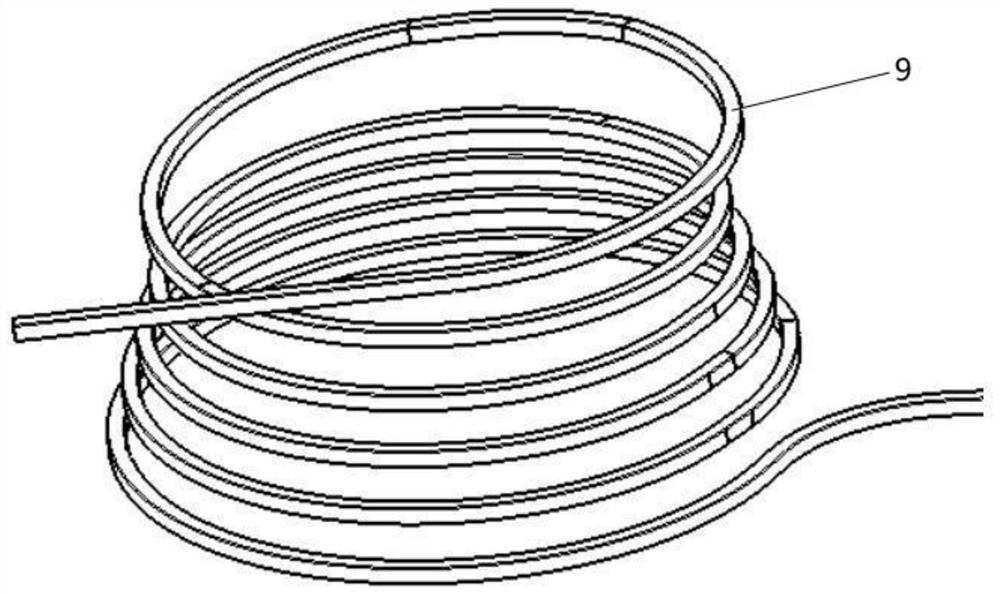

[0037] like figure 1 , 2 Shown, conductor coil 9 in the winding process, the need to open side 90 within the circular outer conductor armor helium racetrack holes 900, but because of site work space is small, the prior art apparatus does not resolve the milling machine class problem.

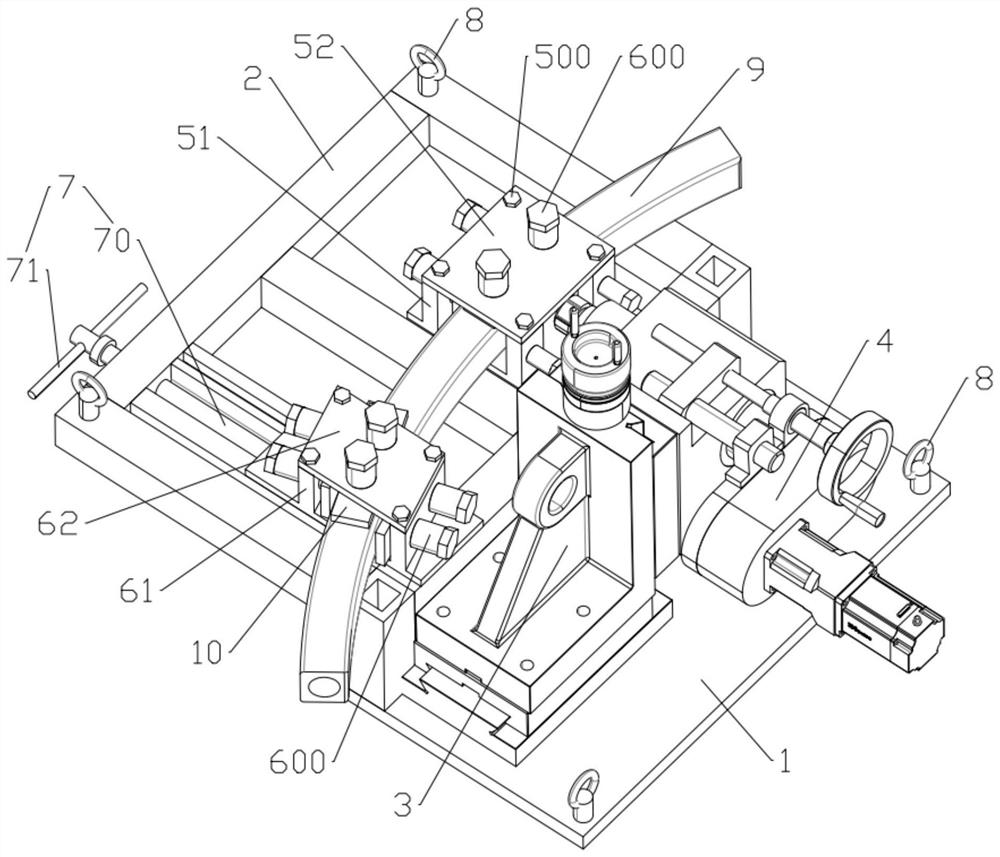

[0038] So, if Figure 3-7 , In the present embodiment, there is provided a small milling machine A work positioning, comprising milling means, the base 1 and the welding line hanging line hanging clamp the front end of the base bracket 2 1, line hanging clamp bracket 2 and base 1 are used alloy steel welding and be annealed, high strength, long life, easy maintenance, greatly reducing the cost. On the clamp bracket 2 is attached to the fixing jig 5 and the movable cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com