Isolated type electrode plate coating wire group for steel slag recycling

A technology of steel slag and electrode plates, applied in the direction of electrodes, electrolytic components, coatings, etc., can solve the problems of low coating content, high coating content in cathode plate grooves, and loss of sponge block coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

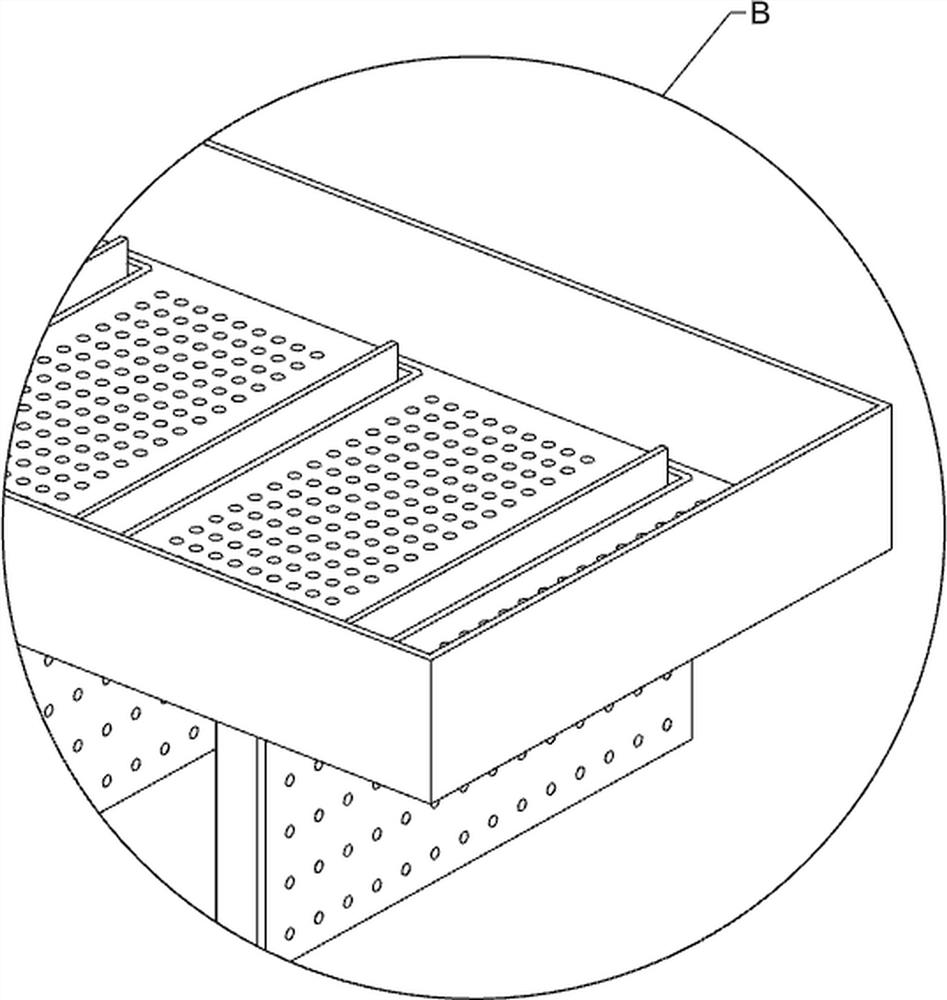

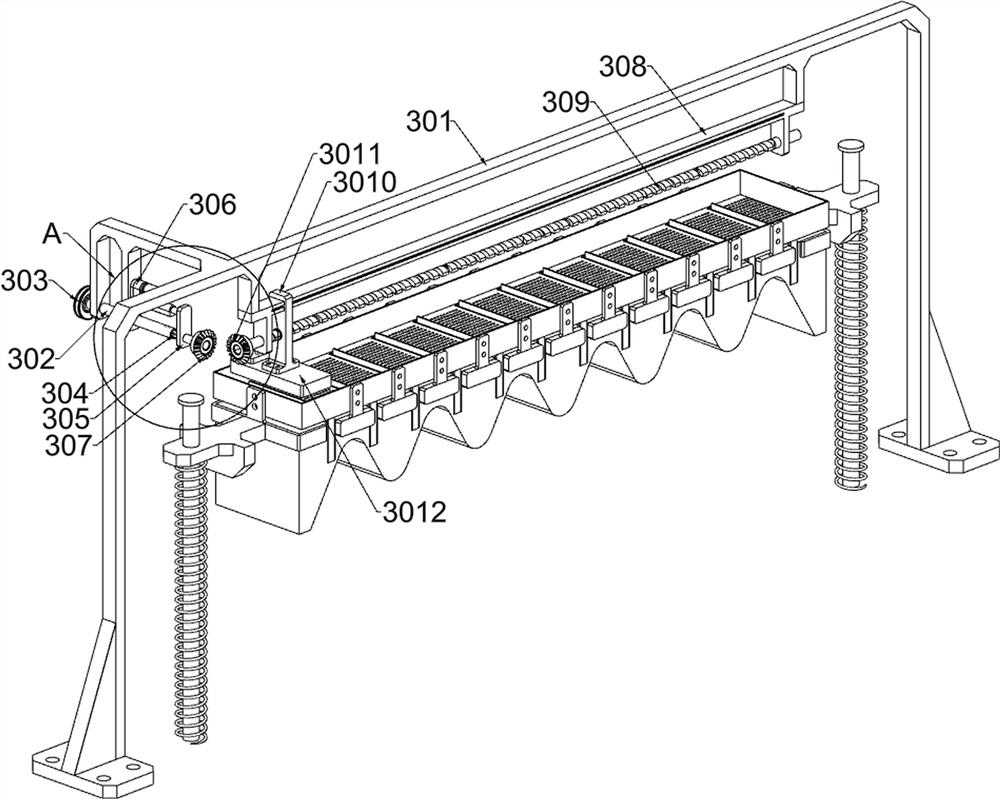

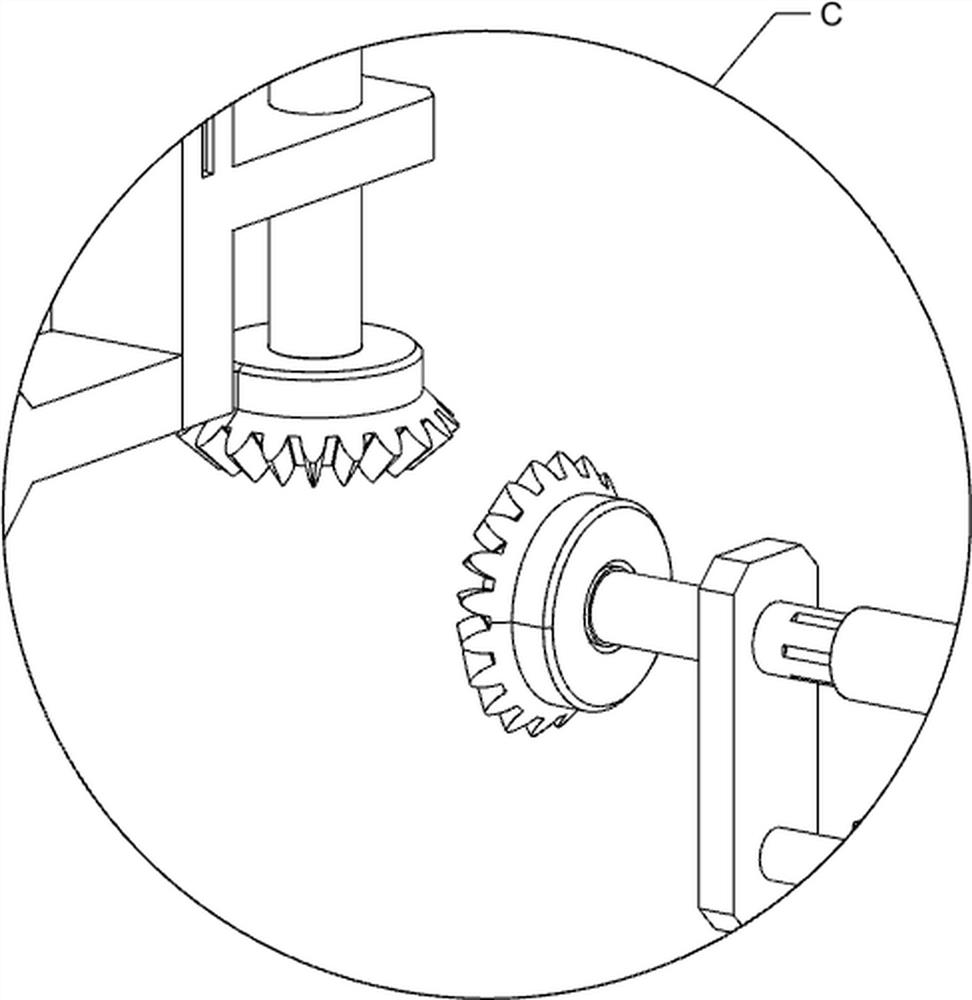

[0037] Isolated steel slag resource electrode plate coating line group, such as Figure 1-2 As shown, including the first working stage 1, the second table 2, the third working stage 3, the first connecting block 4, the second connection block 5, the third connection block 6, the fourth connection block 7, the first electrode Board 8, transport assembly, coating assembly, and cleaning assembly; the first table 1 is fixed to the second table 2; the upper surface of the first table 1 is fixed to the third connecting block 6; the second workbench 2 Secure to the third table 3; the second table 2 is fixed to the first connecting block 4; the second table 2 is fixed to the coating assembly having a coating coating function; the second workbench 2 and has Clean the cleaning assembly of the residual coating function for the fixation; the third table 3 is fixed to the fourth connection block 7; the third table 3 is fixed to the second connection block 5; the third workbensoter 3 is perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com