PTC electric heater, heating device and method for adjusting heating capacity of PTC electric heater

An electric heater and electric heating technology, applied in the direction of ohmic resistance heating parts, ohmic resistance electrodes, etc., can solve the problem of low matching success rate of heating capacity, achieve the effect of reducing error and improving matching success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] This embodiment describes the PTC electric heater of the present invention in detail.

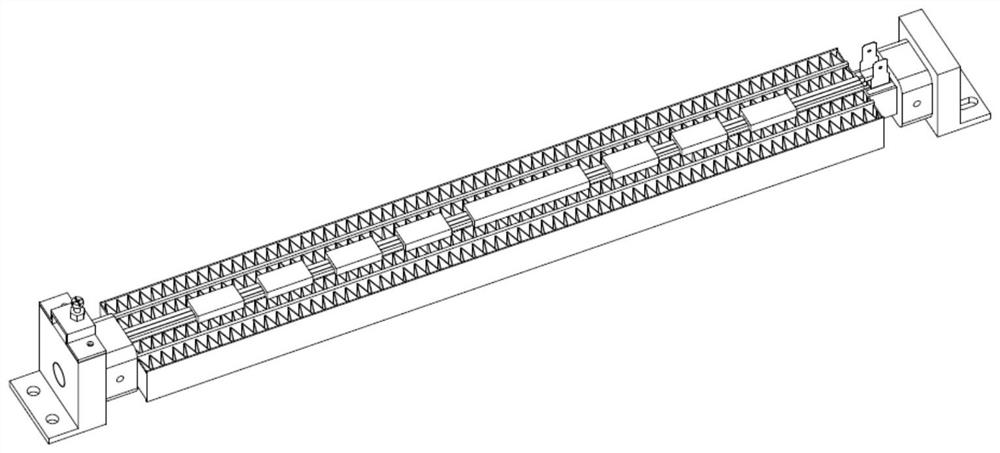

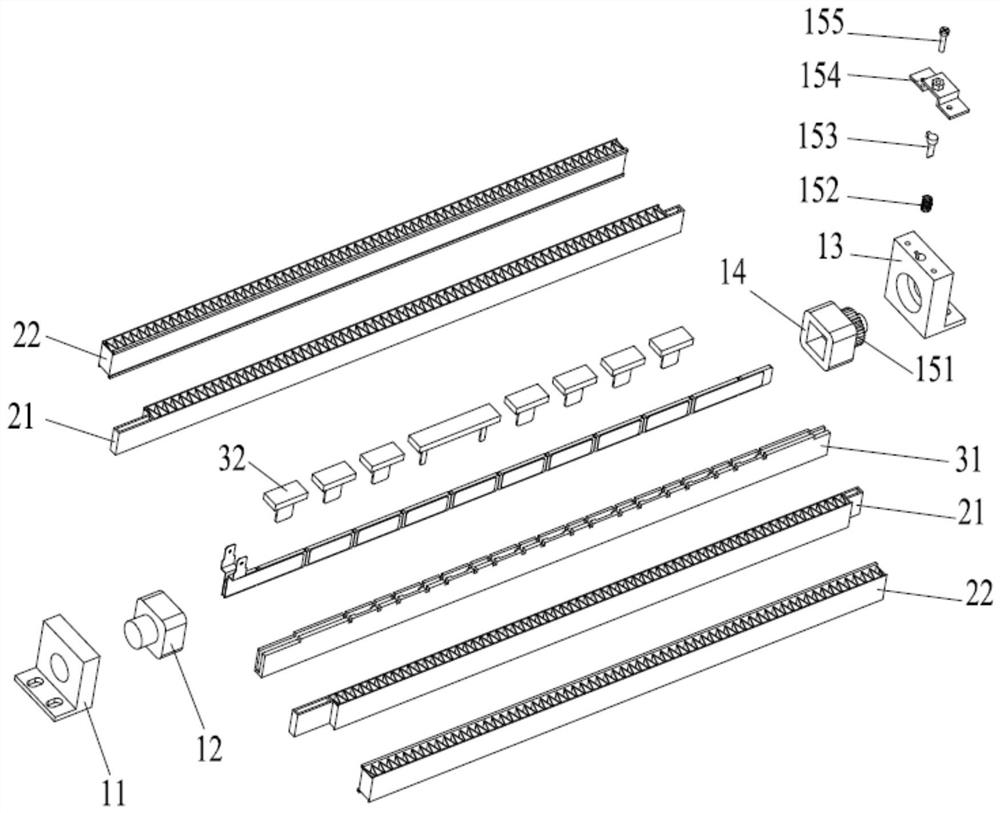

[0069] The PTC electric heater of this embodiment includes a support mechanism and an electric heating mechanism, such as figure 1 shown. Preferably, the electric heating mechanism includes a heat sink assembly and a heating assembly, and the heat sink assembly is installed on both sides of the heating assembly, such as figure 2 shown. The heating component is used for heating, and the heat sink component is used for dissipating the heat generated by the heating component. Preferably, the support mechanism is arranged at both ends of the electric heating mechanism and is rotatably connected with the electric heating mechanism, and a ratchet assembly is provided on the support mechanism, and the ratchet assembly is used to adjust the installation angle of the electric heating mechanism to adjust the head-on wind speed of the electric heating mechanism, such as figure 1 or figure...

Embodiment 2

[0075] On the basis of Embodiment 1, this embodiment describes the specific structure of the support mechanism in detail.

[0076] According to a preferred embodiment, the support mechanism includes a first support mechanism and a second support mechanism, the first support mechanism and the second support mechanism are respectively rotatably connected to the two ends of the electric heating mechanism, and the ratchet assembly is arranged on the second On the second support mechanism. Not limited thereto, the ratchet assembly can also be placed on the first support mechanism; the ratchet assembly can also be disposed on the first support mechanism and the second support mechanism at the same time.

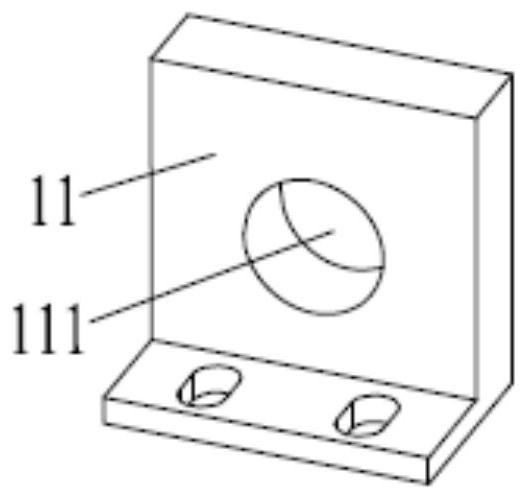

[0077] According to a preferred embodiment, the first support mechanism includes a first shaft seat 11 and a first end shaft 12 . Preferably, the first shaft seat 11 is provided with a first mounting hole 111, and the first end shaft 12 has a first mounting portion 121, a second m...

Embodiment 3

[0082] On the basis of Embodiment 1, this embodiment describes the specific structure of the heat sink assembly in detail.

[0083] According to a preferred embodiment, the heat sink assembly includes a first heat sink 21 and a second heat sink 22, the number of the second heat sink 22 is multiple, the first heat sink 21 is attached to both sides of the heating component, and the second The heat sink 22 and the first heat sink 21 are attached to each other, such as Figure 13 or Figure 14 shown. Preferably, the bonding contact surfaces of the first heat sink 21 and the second heat sink 22 and the bonding contact surfaces on both sides of the second heat sink 22 are provided with a nestable structure, and the first heat sink 21 and the second heat sink 22 are provided with nestable structures. The second cooling fins 22 are nested and connected to each other through a nestable structure, and two adjacent second cooling fins 22 are nested and connected to each other through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com