Double-layer CD reading head based on phase turnover

A read head, double-layer technology, applied in optical recording heads, beam guides, etc., can solve problems such as high cost and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

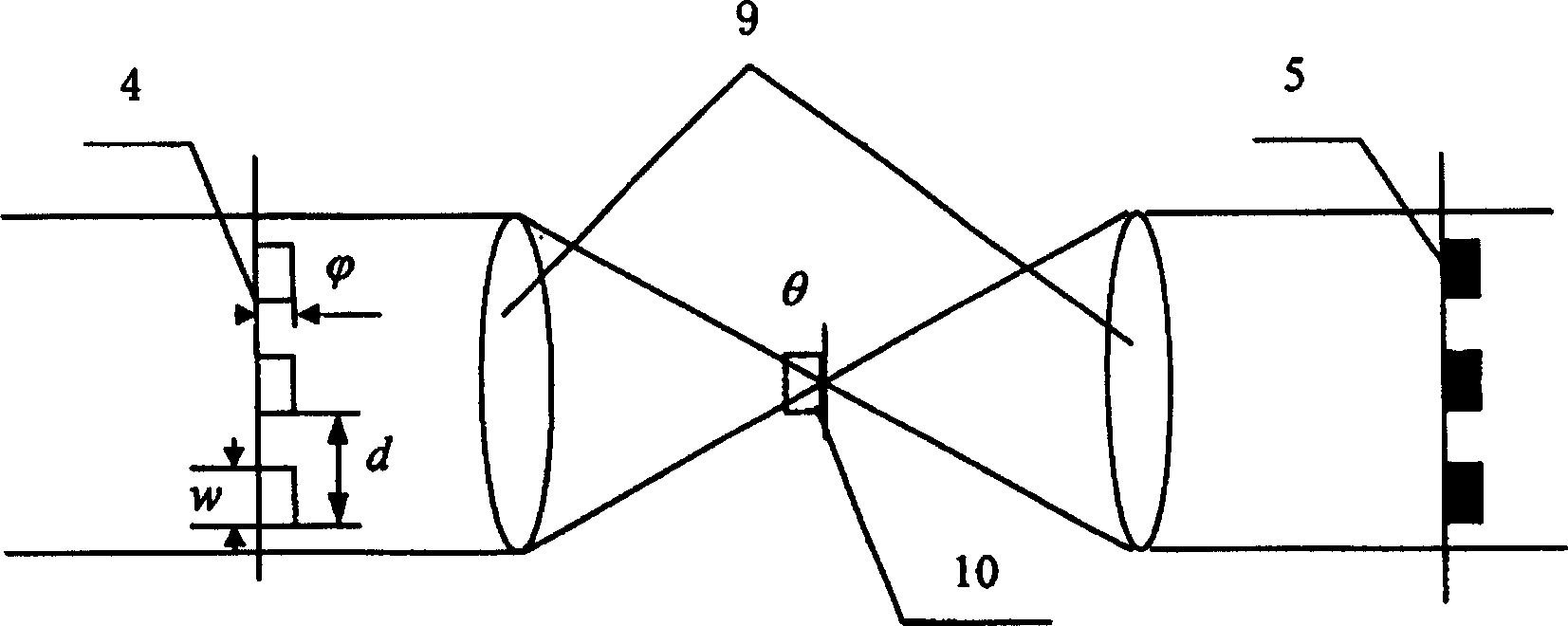

[0020] like Figure 4 In the structure shown, the laser light source 1 has a wavelength of 632.8nm. The illumination beam produced by the He-Ne laser is collimated by the collimator lens 2, and then passes through the first semi-transparent and semi-reflective beam splitter 3, and a beam of light transmitted by it passes through the first The phase plate 4 , the second beam splitter 7 , the third beam splitter 8 , and the lens 9 focus on the first layer of the double-layer optical disc 10 . After being reflected, pass through lens 9, the 3rd beam splitter 8 and the second beam splitter 7 imaging again on the receiving surface by charge coupler (CCD) as detector 6; Another bundle of reflected light passes through second reflector 14 and After two reflections by the first mirror 13 , the second phase plate 12 , the negative lens 11 , the third beam splitter 8 and the lens 9 are used to focus on the second layer of the double-layer optical disc 10 . After being reflected by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com