High-power cylindrical lithium ion battery and processing technology

A technology of lithium-ion battery and processing technology, which is applied in the direction of secondary battery, battery pack parts, battery box/coating, etc., which can solve problems such as internal corrosion, difficulty in electrolyte absorption, and complicated process of pole pieces, so as to reduce damage, Good for popularization and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

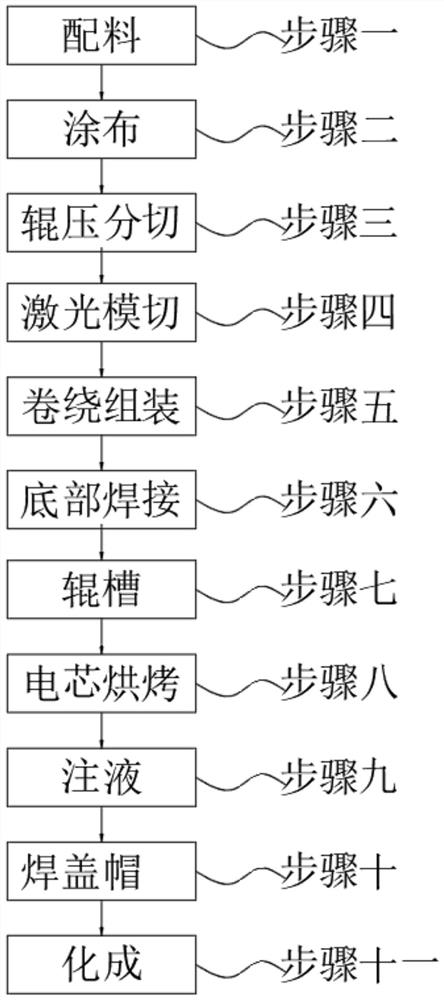

[0032] Processing process of high power cylindrical lithium ion battery, including steps 1, ingredient; step two, coating; step three, roller pressure; step four, laser die; step five, wound assembly; step six, bottom Welding; step seven, roller groove; step eight, battery baking; step nine, liquid; Step 10, welding the cap; step eleven, chemical form;

[0033] In the above steps, the number of pieces of nano-grade lithium iron phosphate and 15 parts of microtoxium phosphate is mixed, and a positive electrode active material is made, and the number of parts by 80 parts is made of 80 parts. The active substance and 2 parts of the binder, 2 parts of the conductive agent were added to the vacuum stirring tank, and stirring was carried out using an ultrasonic stirring apparatus, and a positive electrode slurry was made; the weight of 80 parts was 80 parts of the negative electrode active substance, 2 parts. The binder and 2 parts of the conductive agent were added to the vacuum stirri...

Embodiment 2

[0045] Processing process of high power cylindrical lithium ion battery, including steps 1, ingredient; step two, coating; step three, roller pressure; step four, laser die; step five, wound assembly; step six, bottom Welding; step seven, roller groove; step eight, battery baking; step nine, liquid; Step 10, welding the cap; step eleven, chemical form;

[0046] Wherein said step a, the nanoscale lithium iron phosphate 4 parts by weight, respectively micrometric mixing lithium iron phosphate and 12 parts of a positive electrode active material, the weight of the parts are made of positive electrode 90 parts 5 parts of active substance and a binder, 5 parts of conductive agent added to the vacuum mixing tank, stirred by ultrasonic mixing equipment to prepare a positive electrode slurry; 90 parts by weight, respectively the negative electrode active material, 5 parts 5 parts of a binder and a conductive agent is added to the vacuum mixing tank, stirred by ultrasonic mixing equipment ...

Embodiment 3

[0058] Processing process of high power cylindrical lithium ion battery, including steps 1, ingredient; step two, coating; step three, roller pressure; step four, laser die; step five, wound assembly; step six, bottom Welding; step seven, roller groove; step eight, battery baking; step nine, liquid; Step 10, welding the cap; step eleven, chemical form;

[0059] Wherein said step a, the nanoscale parts by weight of lithium iron phosphate were 5 parts of lithium iron phosphate micron and mixing 8 parts of a positive electrode active material, the weight of the parts are made of positive electrode 95 parts 8 parts of active substance and a binder, 8 parts of a conductive agent were added to the vacuum mixing tank, stirred by ultrasonic mixing equipment to prepare a positive electrode slurry; 95 parts by weight respectively of the negative electrode active material, 8 parts 8 parts of a binder and a conductive agent is added to the negative electrode slurry was vacuum stirred tank, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com