Trace element detection device and method based on labeling technology

A technology for trace elements and detection devices, which is applied in the field of trace element detection devices based on standard addition technology, can solve the problems of easy contamination and large influence of human factors, and achieves improved accuracy, simple structure, reduced cross-contamination and The effect of the difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

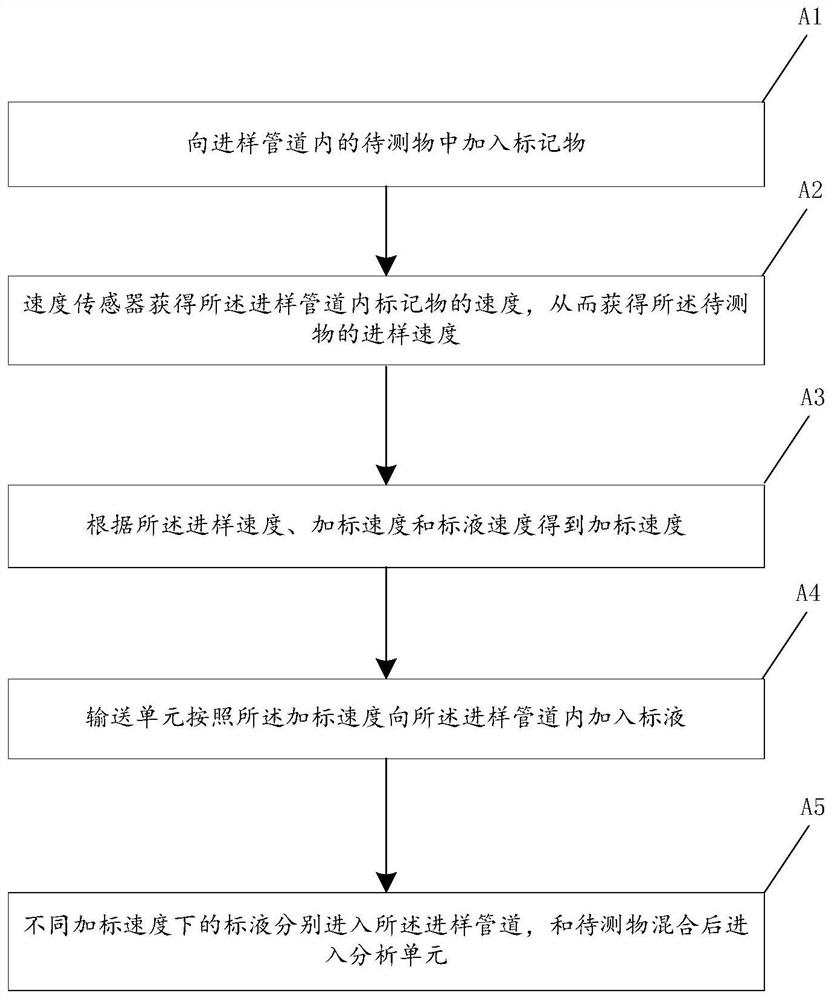

Image

Examples

Embodiment 1

[0034] The trace element detection device based on the standard addition technology according to the embodiment of the present invention, the trace element detection device based on the standard addition technology includes:

[0035] An analysis unit and a first pipeline, the analyte enters the analysis unit through the first pipeline, such as ICP-MS;

[0036] a marker applying unit, the marker applying unit is used to add markers to the analyte in the first pipeline;

[0037] a speed sensor, the speed sensor is used to detect the speed of the marker in the first pipeline to obtain the sampling speed of the analyte;

[0038] a second pipeline, one end of the second pipeline communicates with the first pipeline between the analysis unit and the speed sensor, and the other end communicates with the delivery unit;

[0039] A conveying unit, the conveying unit is used to push the standard liquid at different adding speeds, and the standard liquid enters the first pipe from the se...

Embodiment 2

[0063] An application example of the trace element detection device and method based on the standard addition technology in the semiconductor industry according to Embodiment 1 of the present invention.

[0064] In this application example, the analysis unit adopts ICP-MS; the speed sensor includes a first photoelectric sensor, a second photoelectric sensor and a calculation module, and the two photoelectric sensors are sequentially arranged on the first pipeline; the marker applying unit adopts a gas pipeline and a second photoelectric sensor. The combination of the two valves, the marker is gas (not limited to this, as long as the speed sensor can identify it), and when the gas enters the object to be tested in the first pipeline, it becomes a bubble; the delivery unit includes a temporary storage module and a delivery pump, The temporary storage module adopts a buffer ring, and the transfer pump adopts a syringe pump. The liquid storage volume of the buffer ring is the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com