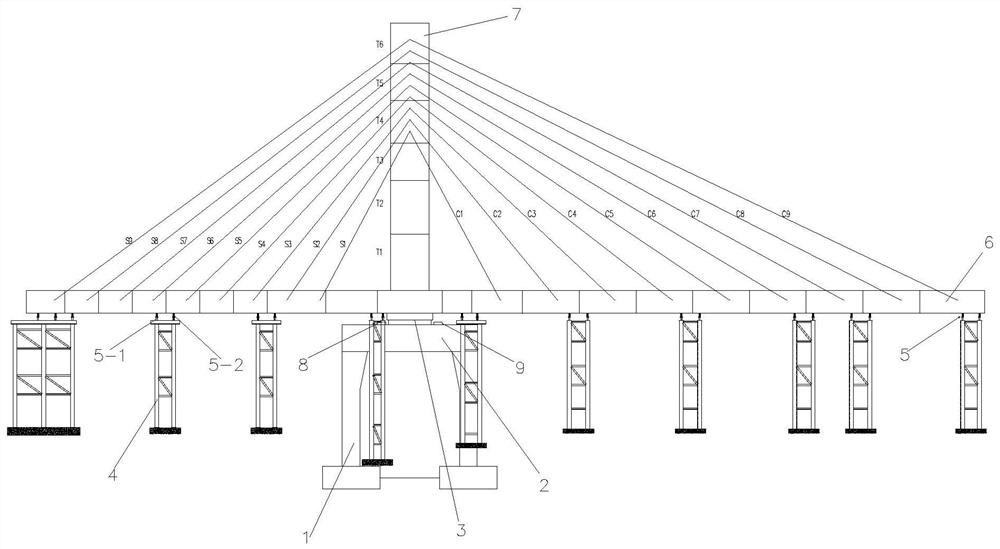

Construction method for cooperative tensioning of a prestressed steel beam and a stay cable of a cover beam

A technology of prestressed steel beams and construction methods, which is applied in the direction of cable-stayed bridges, bridges, bridge parts, etc., to achieve the effects of reasonable design, guaranteed verticality of bridge towers, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] like figure 1 and Figure 5 Shown, the present invention comprises the following steps:

[0072] Step 1. Construction and marking of prestressed steel tendons in the cap beam:

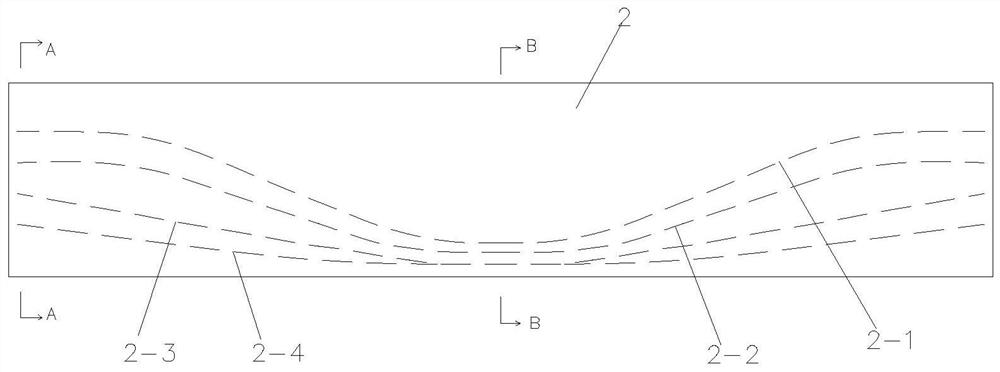

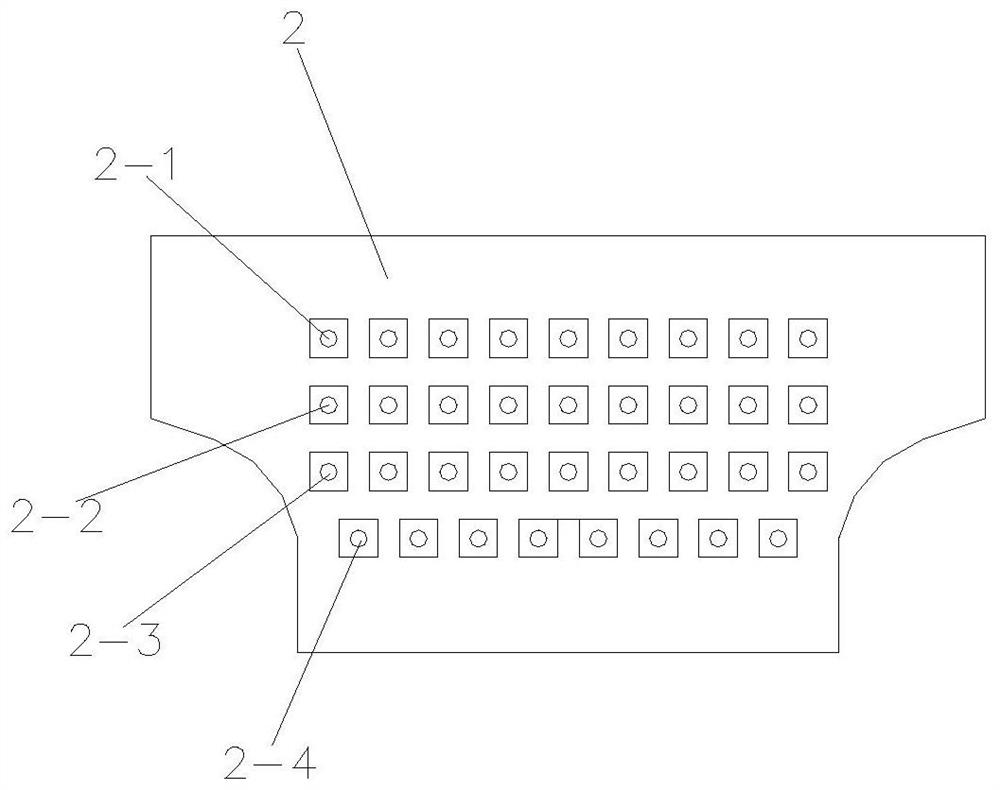

[0073] Step 101, performing cover beam construction on the pier column 1 to form a cover beam 2; wherein, a spherical joint 3 is set at the center of the cover beam 2;

[0074] Step 102, thread the prestressed steel tendons in the cover beam 2, and mark the prestressed steel tendons as the first row of prestressed steel tendons, ..., i-th row of prestressed steel tendons, ... , the first row of prestressed steel tendons; wherein, i and I are both positive integers, and 1≤i≤I, the first row of prestressed steel tendons is close to the top surface of the cover beam 2, I=4;

[0075] Step 103, mark the i-th row of prestressed steel tendons sequentially according to the width direction of the cover beam 2 as the first prestressed steel tendon in the i-th row, ..., the j-th prestressed steel tendon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com