Feeding device for rotary swaging forming

A feeding device and guide rail technology, which is applied in the field of rotary forging feeding devices, can solve problems such as upsetting, and achieve the effect of convenient control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

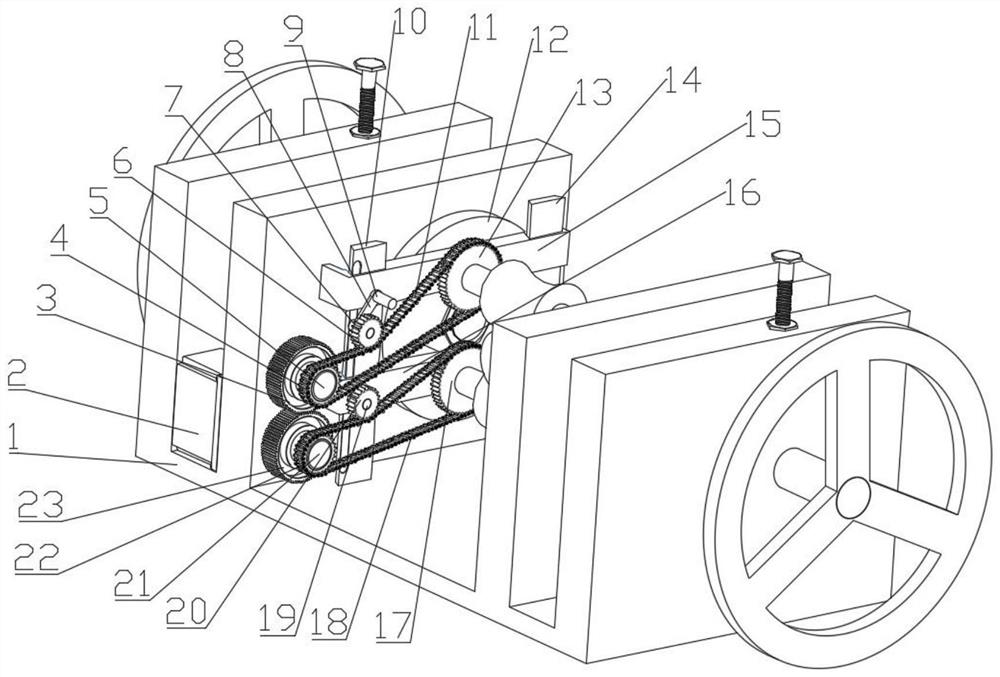

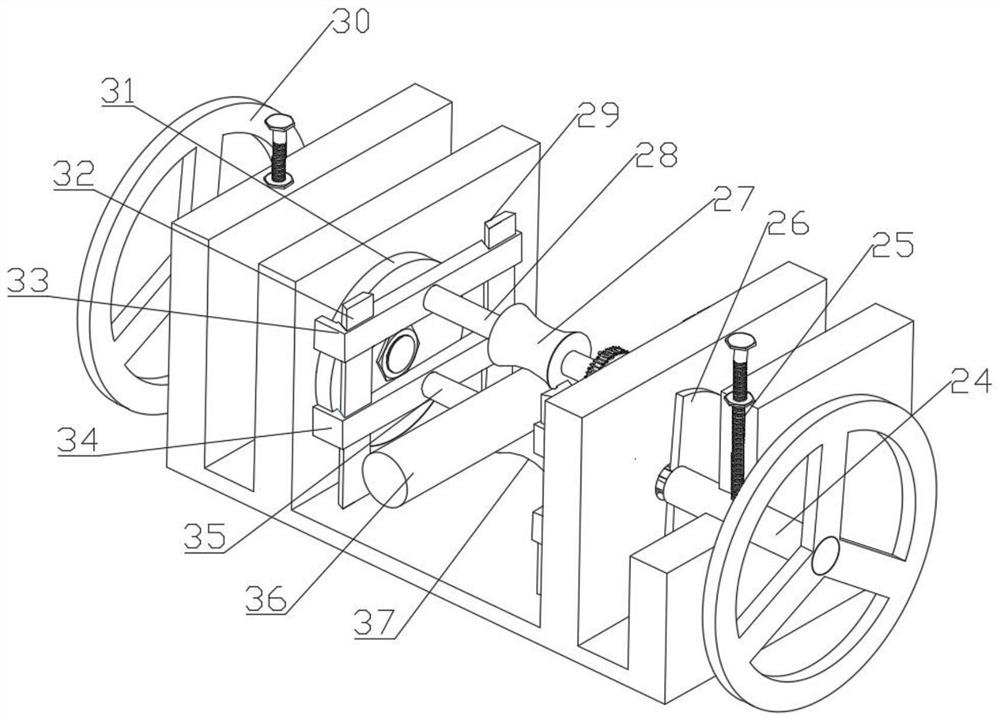

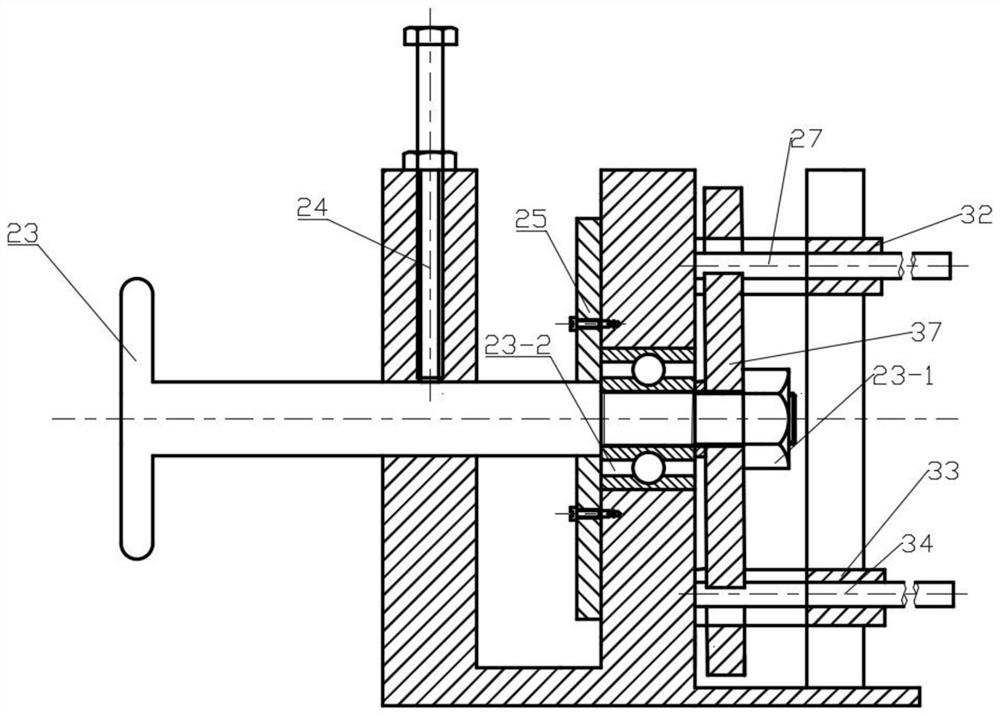

[0034] The material introduction device for rotary swaging involved in the present invention will be further described below with reference to the accompanying drawings.

[0035] figure 1 It is a structural schematic diagram of a material introduction device for swaging forming according to the present invention, figure 2It is a schematic view from another perspective of the structure of the swaging feeding device of the present invention. It is mainly composed of a base (1), a motor (2), an adjustment mechanism, a clamping mechanism, a transmission mechanism and a tensioning mechanism. The adjustment mechanism includes guide rails (14, 29, 32), chute guide rails (10), beams (15, 16, 33, 34), slide bars (7, 19), connectors (8), fixed rods (9), Adjust shaft (24, 30), stop screw (25). Among them, the chute guide rail (10) cooperates with the beam (15, 16) through the dovetail groove (15-1); . The tensioning mechanism comprises a slide bar (7, 19), a connecting piece (8), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com