Multifunctional end effector for aerospace maintenance

An end-effector and multi-functional technology, applied in the field of satellite maintenance, can solve the problems of lack of actuators, satellite solar panels cannot be deployed, etc., and achieve the effect of stable and reliable operation and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Referring to the accompanying drawings, the present invention will be further described in detail with specific embodiments.

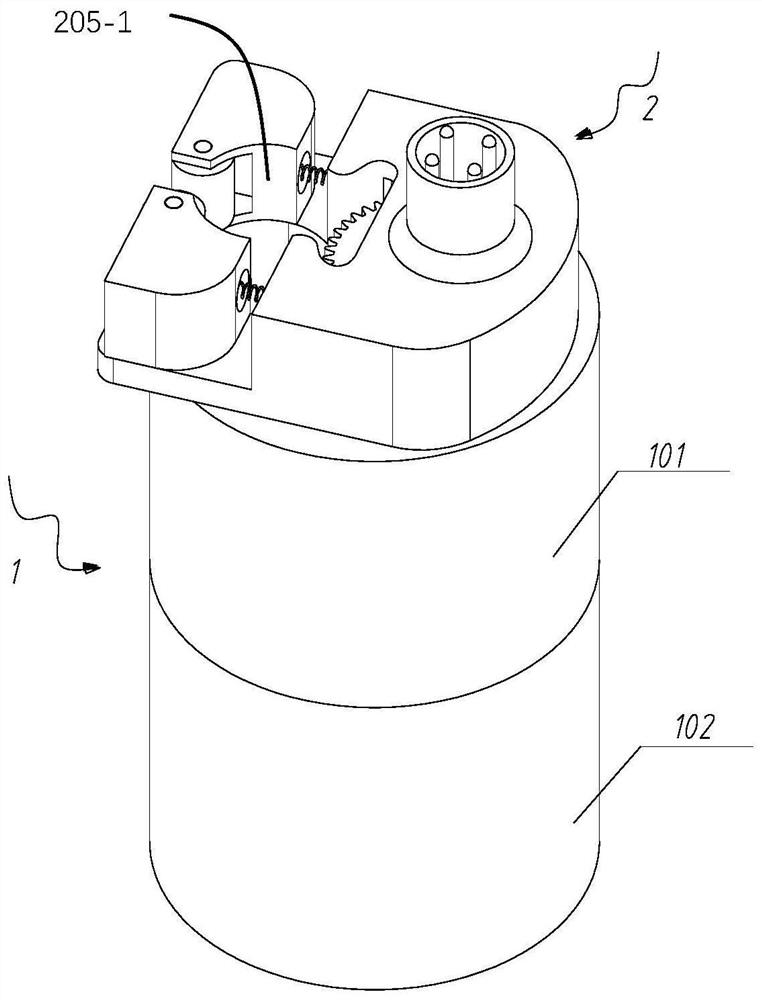

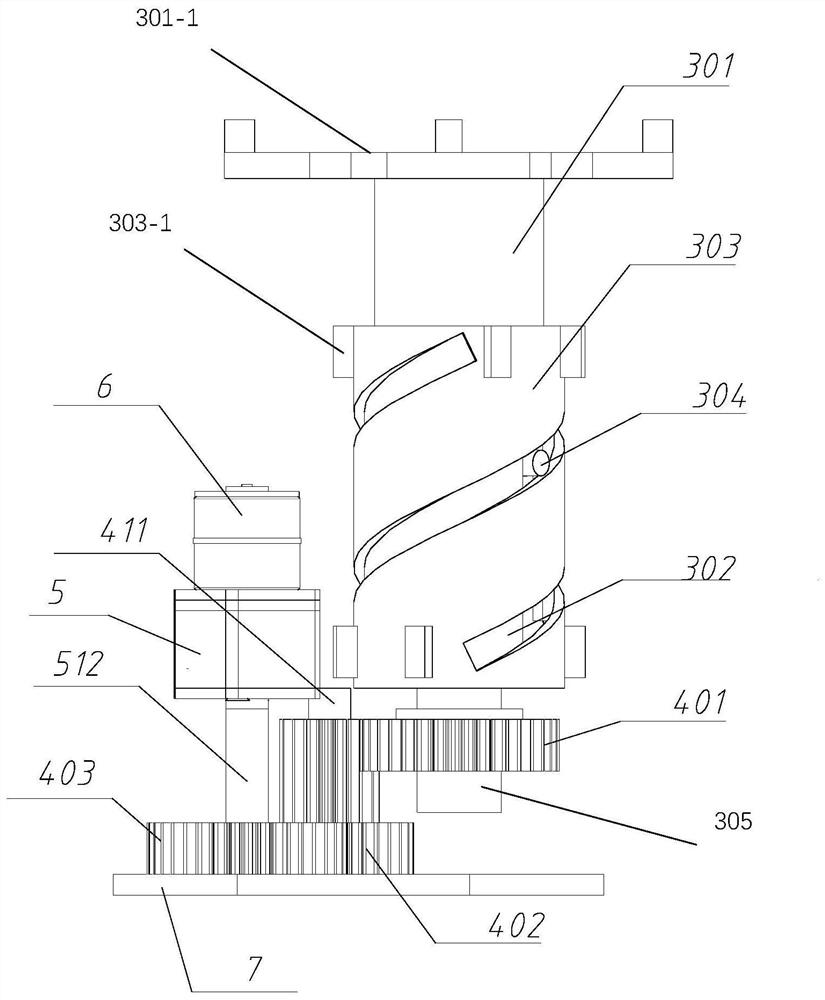

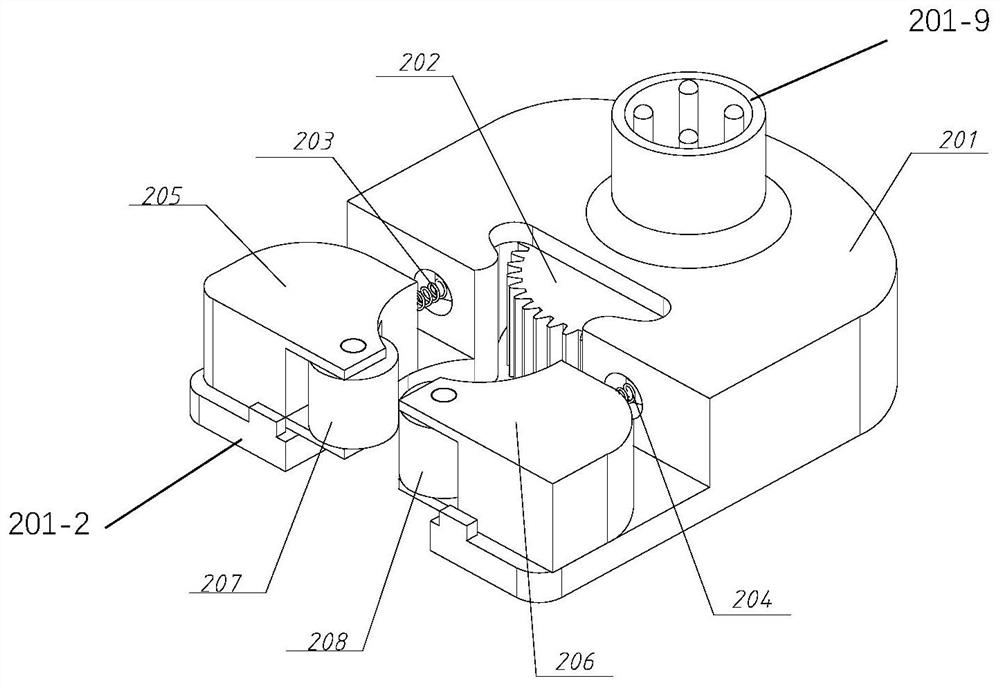

[0048] Such as figure 1 , figure 2 and Figure 18 As shown, the end effector disclosed in the present invention includes a cylindrical shell 1, a gripper mechanism 2, a lifting mechanism 3, a transmission wheel train 4, a reduction gear box 5, a lifting motor 6, a bottom plate 7, a gripper motor 8, and a gripper mechanism 2 is installed on the top of the cylindrical shell 1, and the other mechanisms are located in the cavity of the cylindrical shell 1.

[0049] Such as figure 1 As shown, the cylindrical shell 1 includes two parts, namely an upper shell 101 and a lower shell 102 . The upper casing 101 is fixedly connected with the lower casing 102 . Such as Figure 15 As shown, the top of the upper housing 101 has a spline hole 101-1. Such as Figure 14 As shown, the spline hole 101 - 1 at the top of the upper casing 101 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com