Automatic assembly production line for elevator brake calipers

An automatic assembly and elevator braking technology, which is applied to assembly machines, manufacturing tools, metal processing, etc., can solve the problems of complex assembly process, high manual labor intensity, and large error of inspection accuracy, so as to achieve a simple and compact overall structure and solve problems Difficult to take materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to elaborate the technical solutions adopted by the present invention to achieve the predetermined technical purpose, the technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described implementation The examples are only some of the embodiments of the present invention, not all of the embodiments, and the technical means or technical features in the embodiments of the present invention can be replaced without creative work. The following will refer to the accompanying drawings in conjunction with Examples are given to illustrate the present invention in detail.

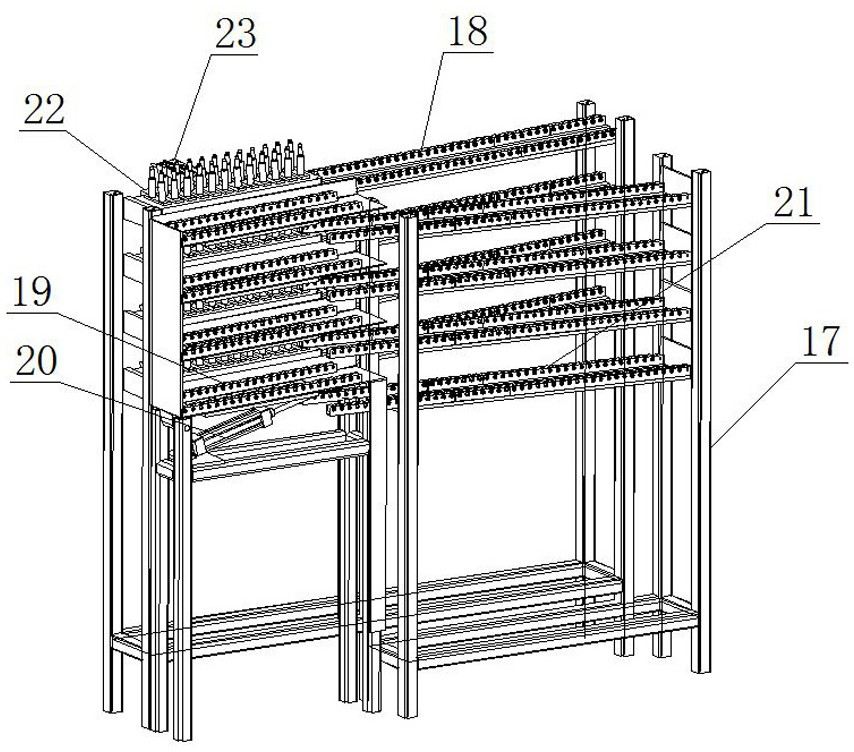

[0028] like figure 1As shown, an elevator brake caliper automatic assembly production line of the present invention includes a carrier plate conveying device 1 and a brake plate storage mechanism 2 and a brake plate carrier plate feeding mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com