Bypass coupling three-wire indirect electric arc welding method with controllable electric arc space structure

A technology of bypass coupling and space structure, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve problems such as unfused side walls, increased welding current, and narrow welding process parameters in narrow gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

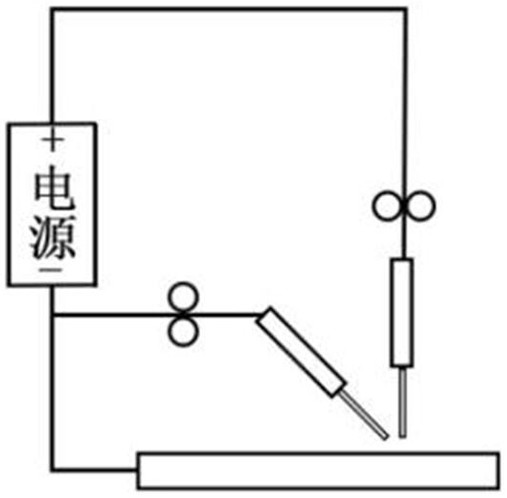

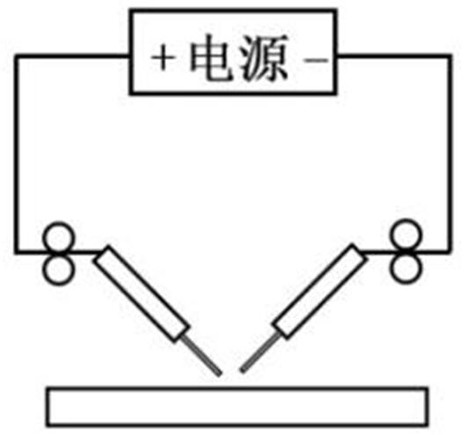

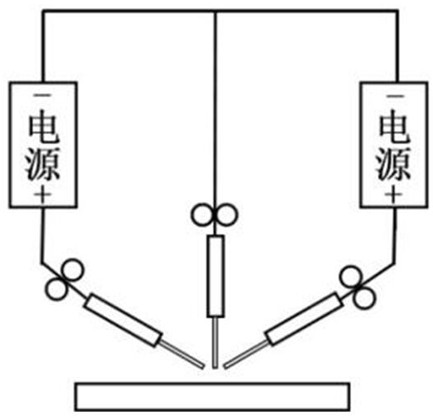

[0036] Narrow gap welding is carried out by adopting a bypass coupling three-wire indirect arc welding method with controllable arc space structure described in the present invention. The base material is 300×150×30mm (length×width×height) Q235 steel plate, the welding wire is ER50-6, the diameter of the main wire is 1.6mm, the diameter of the side wire is 1.2mm, and the welding shielding gas is Ar+20%CO 2 And sent out by the main wire welding torch, the air flow rate is 15-20L / min; the weld groove form adopts type I groove, and the groove gap is 10mm. The specific welding process is as follows:

[0037] Step 1, before welding, connect the three welding wires and the base metal 6 to two power sources respectively, wherein the wires on both sides are connected to the negative pole of the bypass power supply 1 at the same time, and the base metal 6 is connected to the negative pole of the main power supply 2 , the main wire 3 is connected to the positive poles of the two power ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com