Pressing repair equipment for automobile stamping parts

A technology for automotive stamping parts and equipment, which is applied in the field of pressing repair equipment for automotive stamping parts. It can solve problems such as easy shaking and deviation from position, no dust-proof effect, and insufficient stability, so as to improve the efficiency of pressing repair work and easily push out stamping parts. piece of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

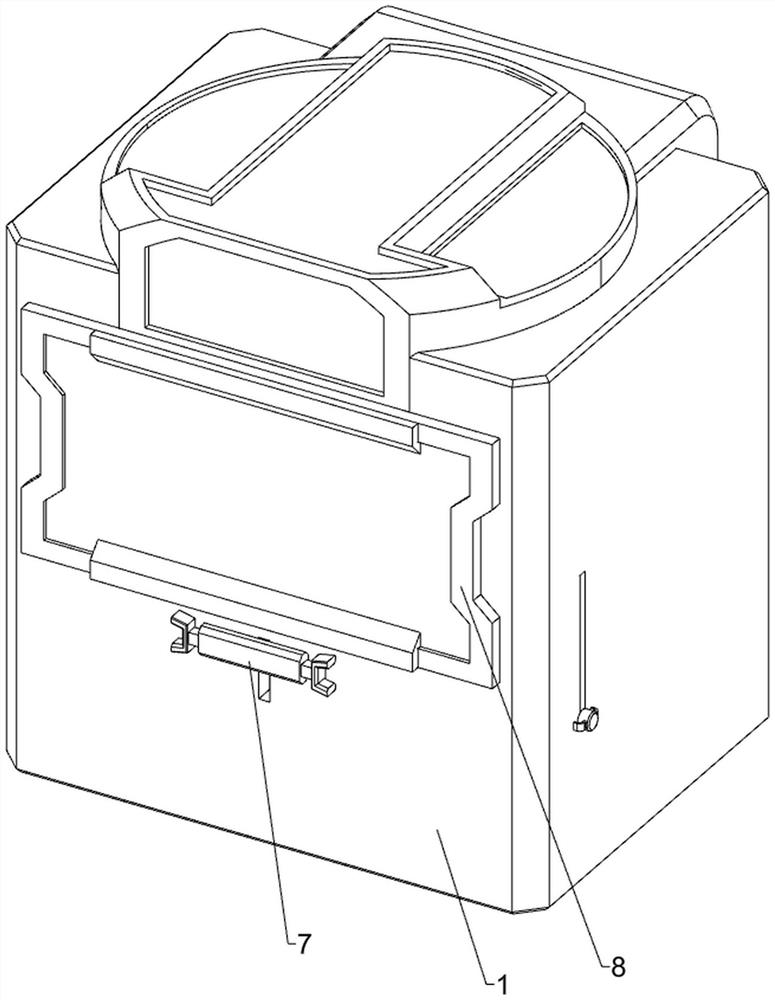

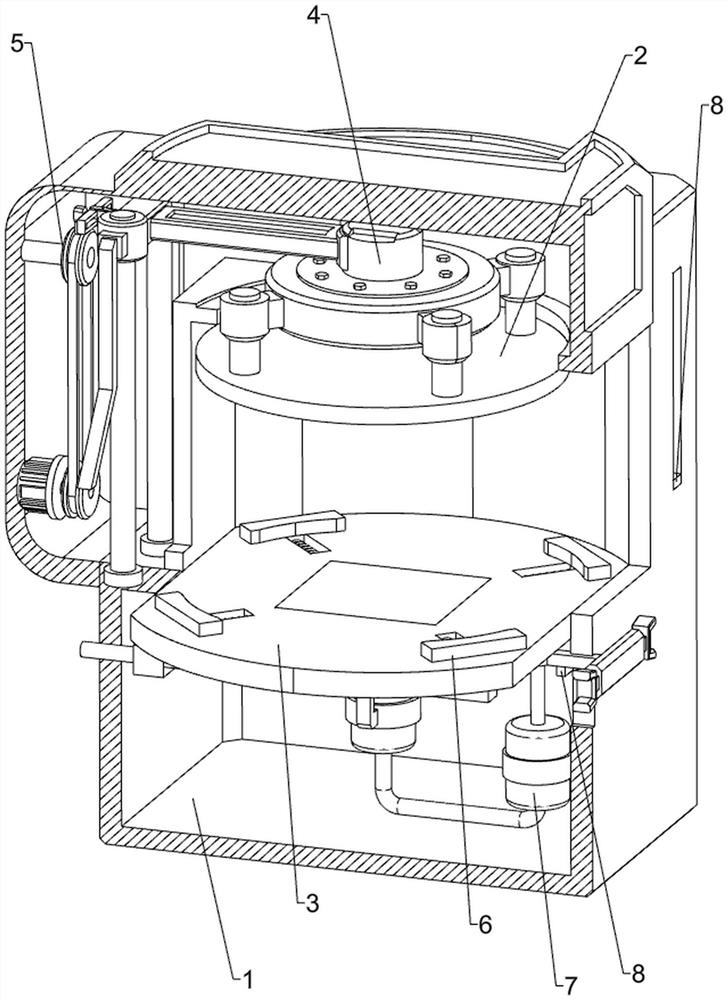

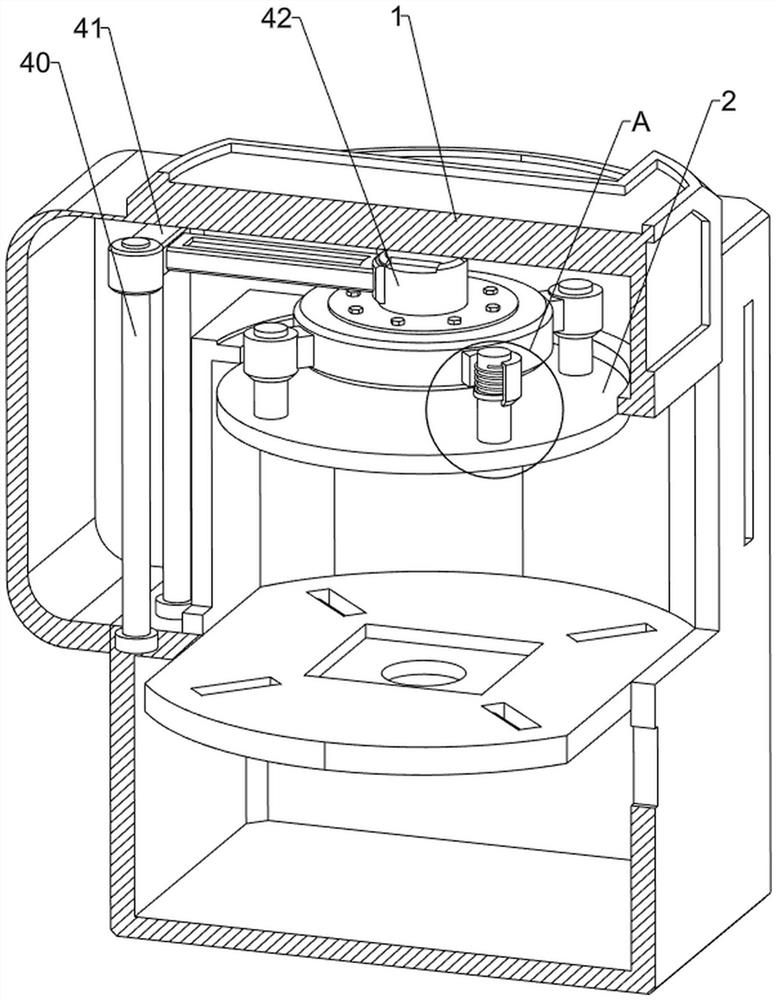

[0035] A kind of pressing repair equipment for automobile stamping parts, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, it includes a housing 1, a pressing block 2, a placement table 3, a pressing mechanism 4, a driving mechanism 5, and a clamping mechanism 6. A pressing mechanism 4 is installed on the upper side of the housing 1, and a pressing block is connected to the pressing mechanism 4. 2. A placement platform 3 is fixedly connected to the middle side of the housing 1 , a drive mechanism 5 is connected between the rear side of the housing 1 and the pressing mechanism 4 , and a clamping mechanism 6 is provided between the placement platform 3 and the pressing mechanism 4 .

[0036] The pressing mechanism 4 includes a guide rod 40, a first slider 41, a special-shaped block 42 and a first spring 43. The rear side of the housing 1 is welded with a guide rod 40 symmetrically on the left and r...

Embodiment 2

[0041] On the basis of Example 1, such as figure 1 , figure 2 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 As shown, a lifting assembly 7 is also included, and the lifting assembly 7 includes a handle 70, a piston cylinder 71, a piston rod 72, a fourth spring 73, an air outlet pipe 74 and a top plate 75, and a sliding type is installed in the middle of the front side of the lower part of the housing 1. Pull handle 70, piston cylinder 71 is installed in the front side of the lower part of the housing 1 and the middle of the bottom of the placing table 3, the upper side of the front side piston cylinder 71 is slidably connected to the piston rod 72, and the inner side of the middle piston cylinder 71 is also slidably connected to the piston Rod 72, the front piston rod 72 is connected with the rear side of the pull handle 70, the fourth spring 73 is connected between the piston rod 72 and the piston cylinder 71, the middle fourth spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com