Double-sided scraping and gluing equipment

A kind of equipment and double-sided technology, which is applied in the field of double-sided scraping and gluing equipment, which can solve the problems of low gluing efficiency and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

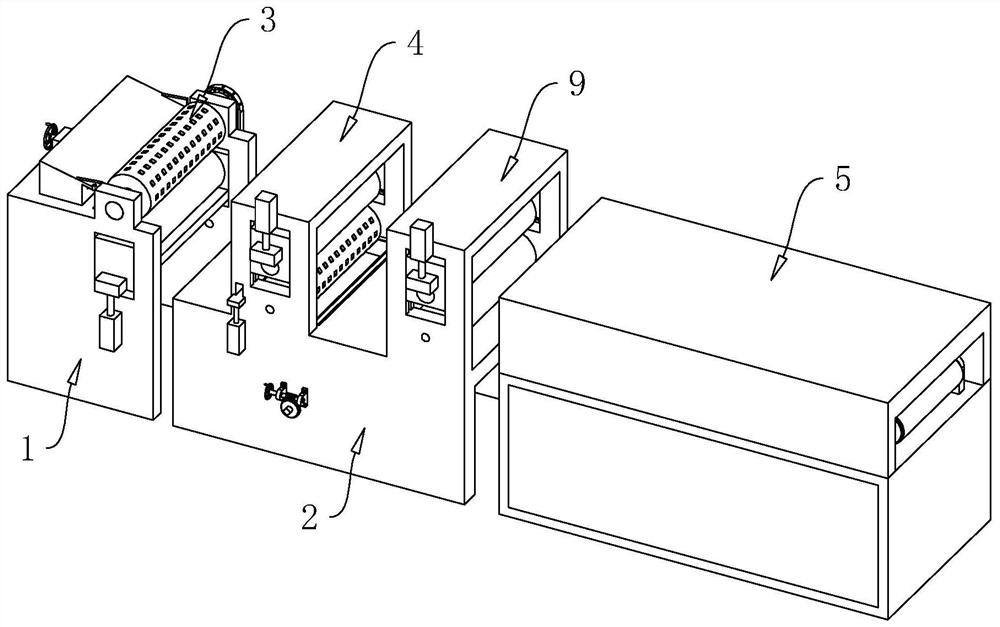

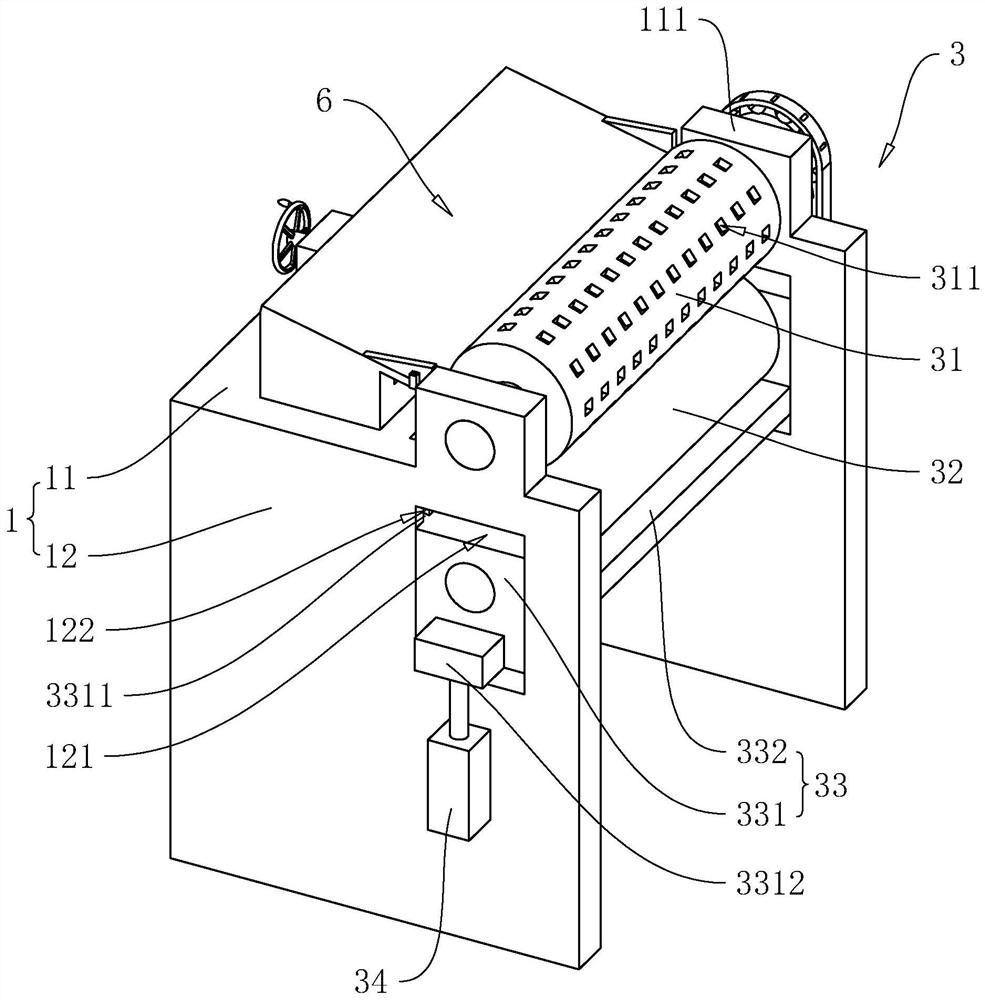

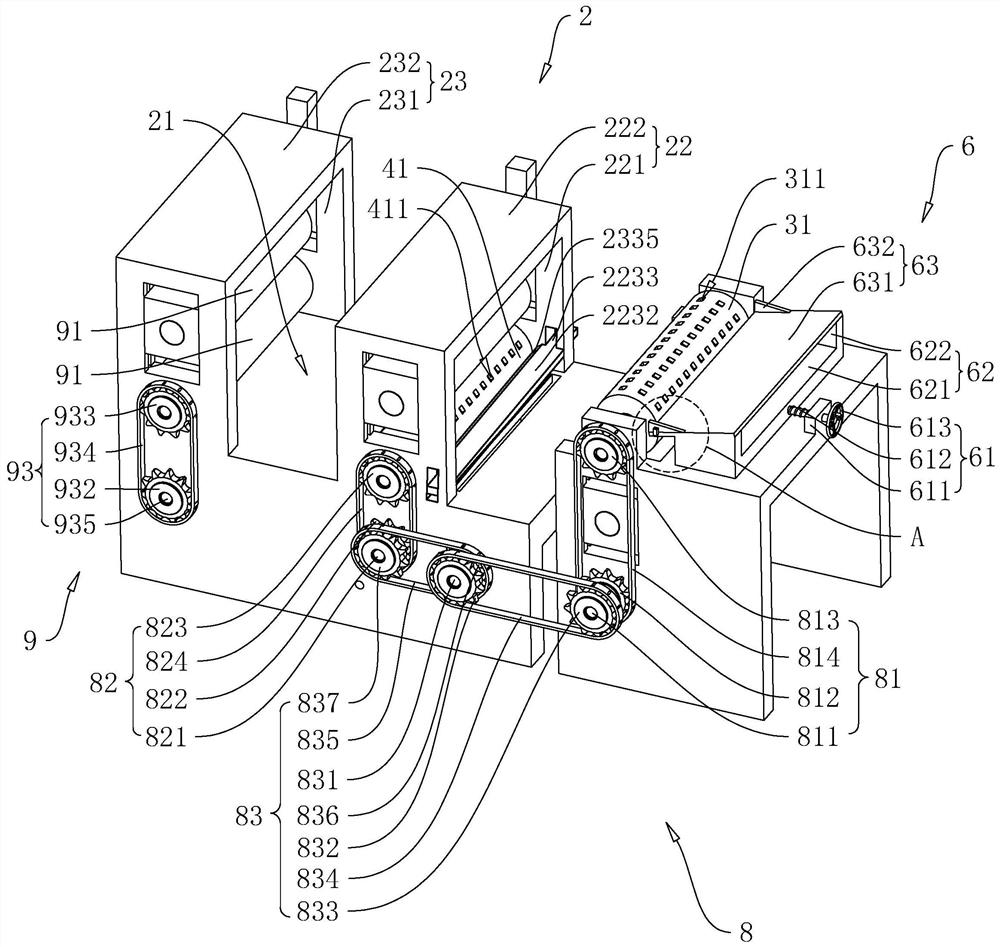

[0052] The following is attached Figure 1-10 The application is described in further detail.

[0053] In this application, the length direction of the double-sided squeegee coating gluing equipment is defined as the first direction, and the width direction of the double-sided squeegee coating gluing equipment is defined as the second direction, based on which the double-sided squeegee coating gluing The device is described.

[0054] A double-sided scraping and gluing equipment, refer to figure 1 and figure 2 , the two sides include a first rack 1 and a second rack 2 arranged in sequence along a first direction. The first frame 1 comprises a first load plate 11 and two first support plates 12 parallel to each other, the first load plate 11 is horizontally arranged, and the two sides of the first load plate 11 are connected with the two first support plates 12 respectively. The inner wall is fixedly connected. The first frame 1 is provided with a front scraping and gluing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com