Suture line with gel coating and preparation method thereof

A suture and gel technology, applied in coatings, medical science, surgery, etc., can solve problems such as rough surface of sutures, weak combination of coatings and sutures, etc., to promote healing, facilitate drug loading, and reduce friction pulling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

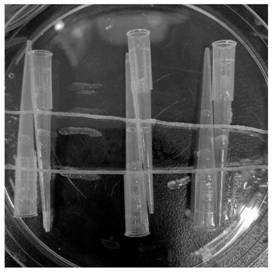

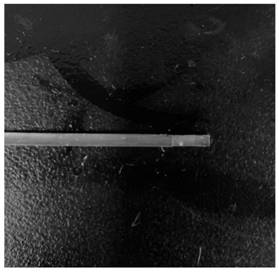

[0051] Embodiment 1 Silk suture surface melting layer formation

[0052] S1. A 16-spindle knitting machine is used, the knitting parameters are gear ratio 81 / 44#, knitting speed 80rmp, the thread body part of the suture thread is made of two strands of raw silk, 2.2Tex silk is used as the shell thread, and 7.3Tex is used. The silk is used as the core wire. According to the requirements of 2-0 in the YY0167-2020 standard, a braided medical suture was designed with a diameter of 0.300-0.349mm.

[0053] S2. Measure the braided silk suture, dip in the mixed solution of lithium bromide solution and BDDE, and prepare a hydrogel on its surface after partially dissolving. Orthogonal tests were carried out on LiBr concentration, reaction temperature and reaction time conditions:

[0054] Lithium bromide concentration: 1M, 2M, 3M, 4M, 5M, 6M, 7M, 8M, 9.3M, 9.5M, 9.8M.

[0055] Reaction time: 1 minute, 3 minutes, 5 minutes, 7 minutes, 10 minutes, 20 minutes, 30 minutes, 40 minutes.

...

Embodiment 2

[0069] Embodiment 2 Utilizes the melt layer to directly form a hydrogel coating on the surface of the silk suture

[0070] S1. A 16-spindle knitting machine is used, the knitting parameters are gear ratio 81 / 44#, knitting speed 80rmp, the thread body part of the suture thread is made of two strands of raw silk, 2.2Tex silk is used as the shell thread, and 7.3Tex is used. The silk is used as the core wire. According to the requirements of 2-0 in the YY0167-2020 standard, a braided medical suture was designed with a diameter of 0.300-0.349mm.

[0071] S2. Measure the braided silk suture, dip in the mixed solution of lithium bromide solution and BDDE, and prepare a hydrogel on its surface after partially dissolving. Orthogonal tests were carried out on the concentration of lithium bromide, the ratio of lithium bromide to suture, the amount of BDDE added to lithium bromide, the reaction temperature and the reaction time:

[0072] Lithium bromide concentration: 1M, 2M, 3M, 4M, 5M...

Embodiment 3

[0079] Embodiment 3 Utilizes melting layer to form composite hydrogel coating on the surface of silk suture

[0080] S1, prepare melted layer according to embodiment 1, specific conditions are as follows:

[0081] Lithium bromide concentration when the molten layer is formed: 7M;

[0082] The ratio of suture to lithium bromide: 1g: 10mL;

[0083] LiBr to BDDE: 1g: 200μL;

[0084] Time: 3 minutes;

[0085] Temperature: 25°C.

[0086] S2. Dip coating in natural polymer solution:

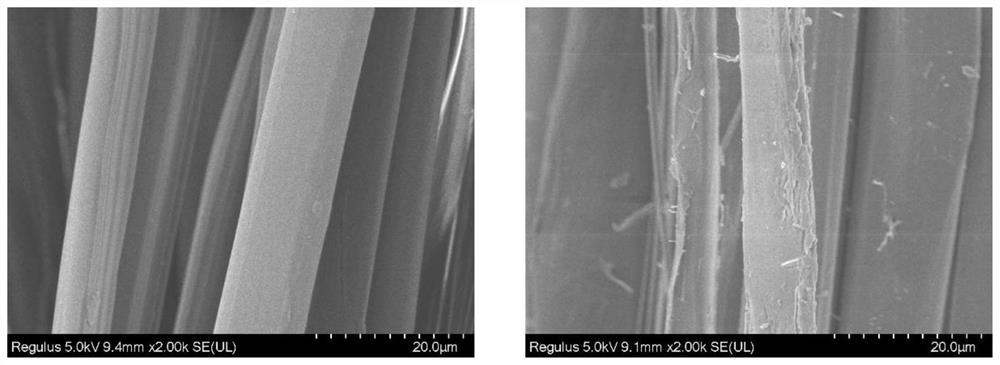

[0087] Silk fibroin solution concentration: 0.5mg / mL, 1mg / mL, 4mg / mL, 7mg / mL, 10mg / mL, 15mg / mL, 20mg / mL, 25mg / mL, 50mg / mL, 75mg / mL, 100mg / mL , 120mg / mL, 125mg / mL, 150mg / mL, 175mg / mL, 200mg / mL, 250mg / mL, 300mg / mL. Silk fibroin ratio BDDE: 1g: 200μL. See figure 2 .

[0088] Concentration of hyaluronic acid solution: 0.5mg / mL, 1mg / mL, 4mg / mL, 7mg / mL, 10mg / mL, 15mg / mL, 20mg / mL, 25mg / mL, 50mg / mL, 75mg / mL, 100mg / mL, 120mg / mL, 125mg / mL, 150mg / mL, 175mg / mL, 200mg / mL, 250mg / mL, 300mg / mL. Hyaluronic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com