A kind of preparation method of cigar flavor extract

A technology of cigars and extracts, which is applied in the field of tobacco flavor extracts, can solve the problems of prolonging the fragrance retention time of cigarettes and not mentioning it, and achieve the goal of prolonging the retention time, improving the sense of layering, and reducing the content of nitrosamines and CO Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

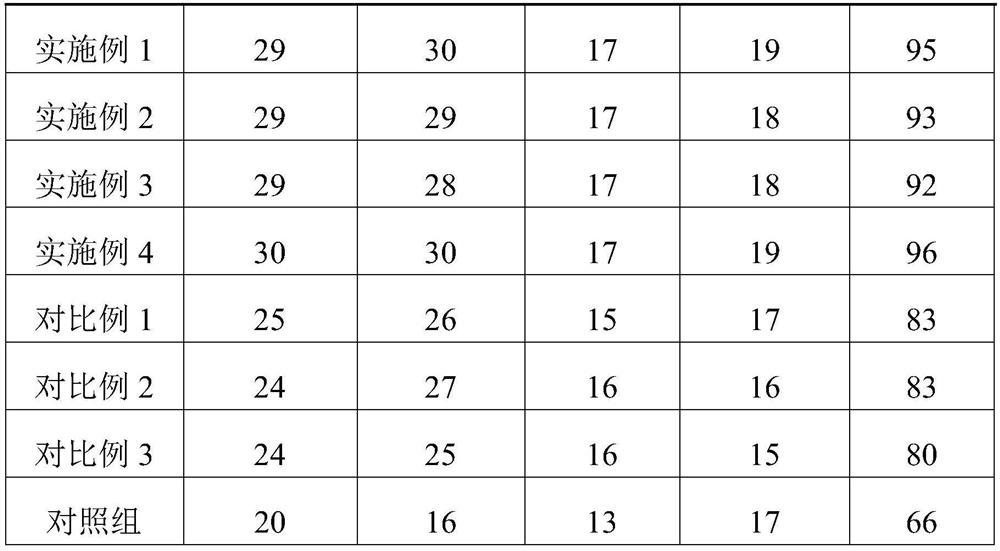

Examples

Embodiment 1

[0025] Embodiment 1 The preparation method of cigar aroma extract extraction

[0026] (1) The raw materials include 35 parts of tobacco leaves, 8 parts of licorice extract, 3 parts of vanilla extract, 7 parts of red date extract, 8 parts of white wine, 0.3 parts of dihydrokiwifruit lactone, 1 part of carob extract, 60 parts of Ethanol solution, 6 parts honey, 3 parts accelerant, and 35 parts water.

[0027] (2) The tobacco leaves are dried by the far-infrared heating and drying method, and the parameters of the far-infrared heating and drying method are set as: the drying temperature is 70° C., the radiation power is 1200W, the radiation distance is 80mm, and the drying time is 25min.

[0028] (3) Mixing liquor, dihydrokiwifruit lactone and water to prepare liquor mixture, soaking the dried tobacco leaves in liquor mixture for 6h.

[0029] (4) drying and pulverizing the soaked tobacco leaves to obtain tobacco leaf powder, adding an ethanol solution with a mass fraction of 20%...

Embodiment 2

[0031] Embodiment 2 The preparation method of cigar aroma extract extraction

[0032] (1) The raw materials include 30 parts of tobacco leaves, 5 parts of licorice extract, 2 parts of vanilla extract, 5 parts of red date extract, 7 parts of white wine, 0.2 parts of dihydrokiwifruit lactone, 0.8 parts of carob extract, 50 parts of Ethanol solution, 5 parts honey, 1 part combustion aid and 20 parts water.

[0033] (2) The tobacco leaves are dried by a far-infrared heating and drying method, and the parameters of the far-infrared heating and drying method are set as follows: the drying temperature is 60° C., the radiation power is 1000W, the radiation distance is 50mm, and the drying time is 20min.

[0034] (3) Mixing liquor, dihydrokiwifruit lactone and water to prepare liquor mixture, soaking the dried tobacco leaves in liquor mixture for 5h.

[0035] (4) drying and pulverizing the soaked tobacco leaves to obtain tobacco leaf powder, adding an ethanol solution with a mass frac...

Embodiment 3

[0037] Embodiment 3 The preparation method of cigar aroma extract extraction

[0038] (1) The raw materials include 40 parts of tobacco leaves, 12 parts of licorice extract, 4 parts of vanilla extract, 9 parts of red date extract, 10 parts of white wine, 0.4 parts of dihydrokiwifruit lactone, 1.2 parts of carob extract, 70 parts of Ethanol solution, 7 parts honey, 5 parts accelerant, and 50 parts water.

[0039] (2) The tobacco leaves are dried by the far-infrared heating and drying method, and the parameters of the far-infrared heating and drying method are set as: the drying temperature is 75°C, the radiation power is 1400W, the radiation distance is 100mm, and the drying time is 30min.

[0040] (3) Mixing liquor, dihydrokiwifruit lactone and water to prepare liquor mixture, and soaking the dried tobacco leaves in liquor mixture for 7h.

[0041] (4) drying and pulverizing the soaked tobacco leaves to obtain tobacco leaf powder, adding an ethanol solution with a mass fractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com