Heating assembly for discharging device

A technology of discharging device and heating components, which is applied in application, food forming, cocoa, etc., can solve the problems of uneven discharging speed and lower chocolate temperature, and achieve the effect of ensuring the discharging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

[0032] The present application discloses a heating assembly capable of outputting different heating temperatures at different locations within the housing assembly.

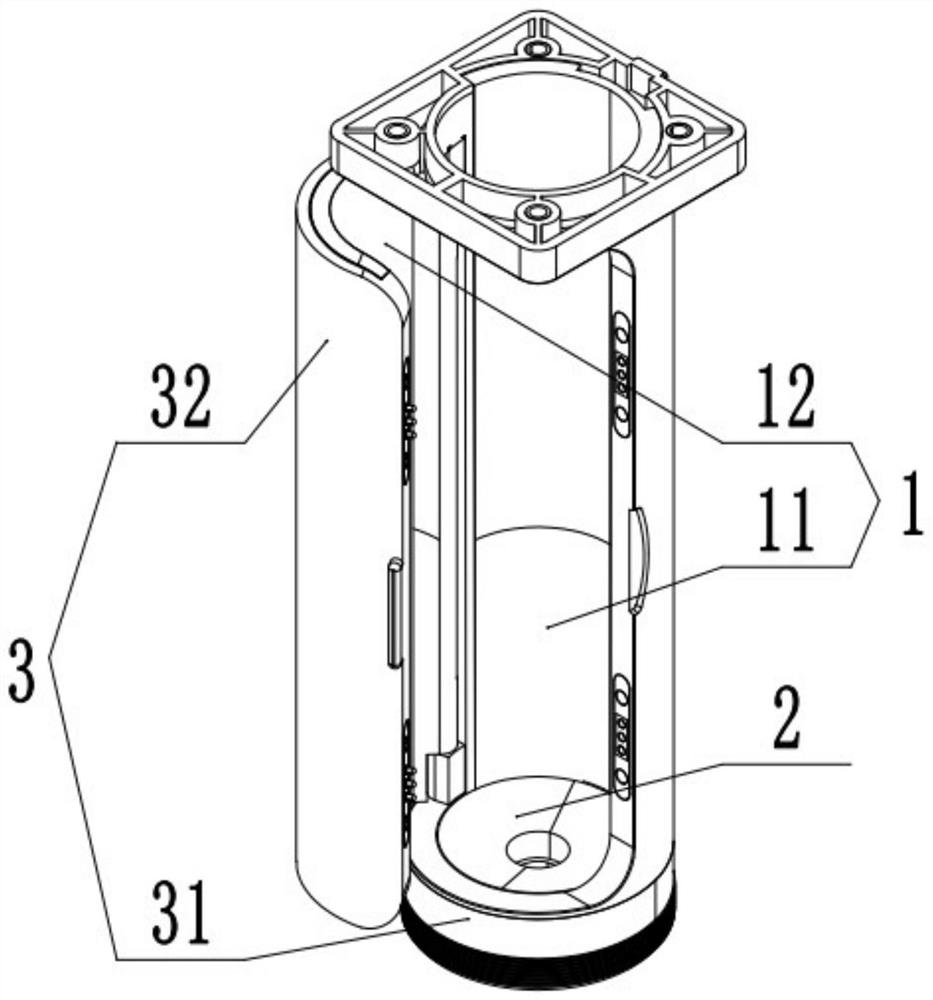

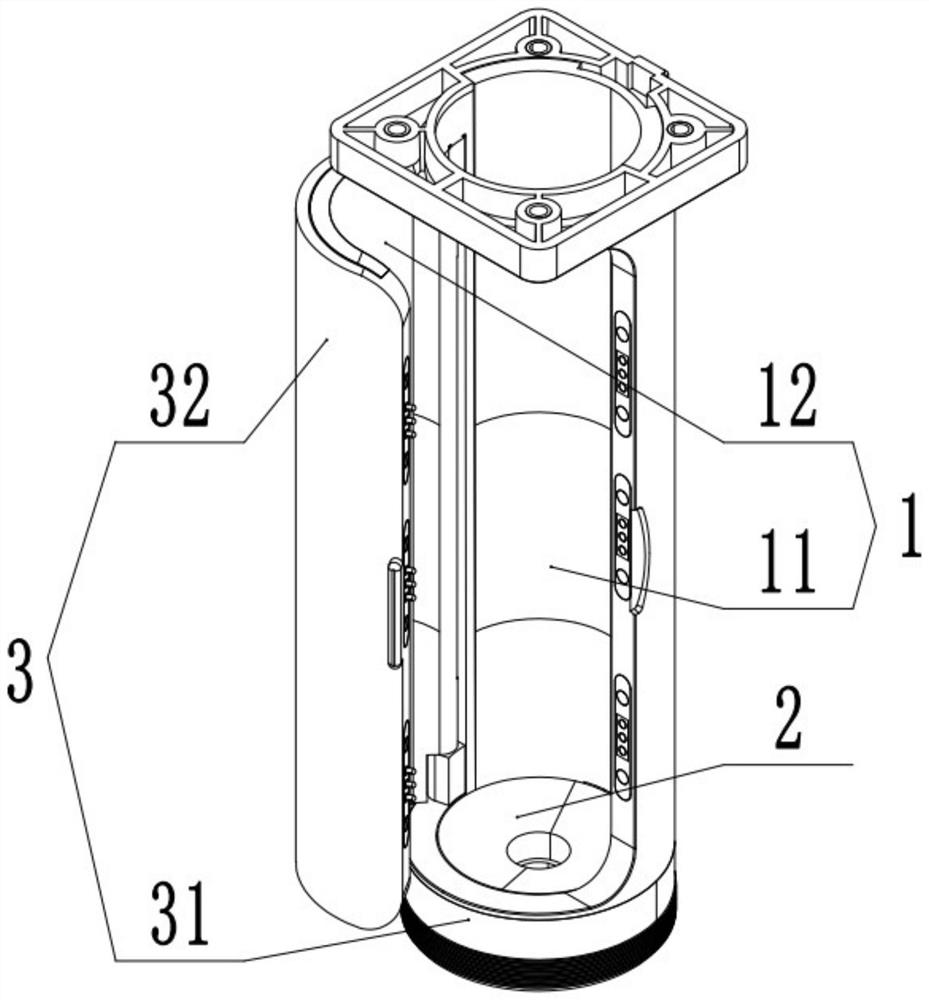

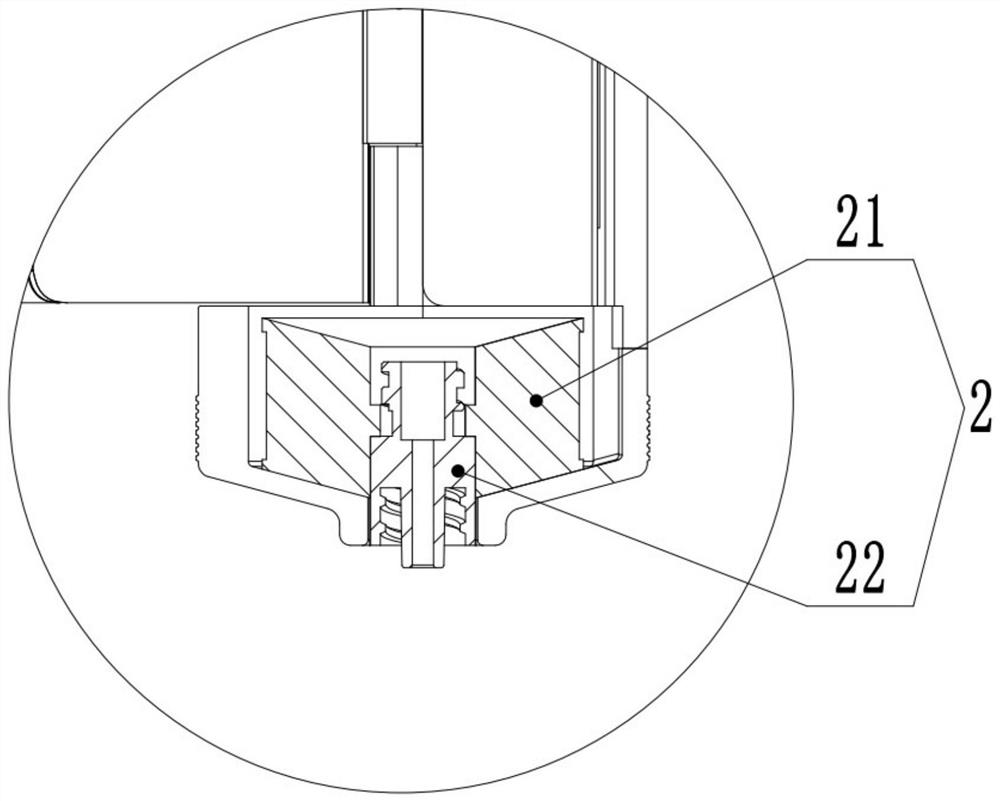

[0033] The heating assembly includes: a barrel unit 1 , a base unit 2 and a control unit.

[0034] The heating assembly is used in a discharge device, and the discharge device includes: a heating assembly, a shell assembly 3, a base 4, a driving assembly and a material pipe.

[0035] The shell assembly 3 is fixed on one end of the base 4, and the end of the shell assembly 3 far away from the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com