Micromechanical acoustic transducer

An acoustic transducer, transducer technology, applied in semiconductor electrostatic transducers, microphones, piezoelectric/electrostrictive transducers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Before describing the embodiments of the present invention in detail based on the drawings below, it should be noted that in different drawings, elements, objects and / or structures that are the same and have the same function or action are provided with the same or similar drawings Labels are used so that the descriptions of these elements in different embodiments are interchangeable and / or mutually applicable.

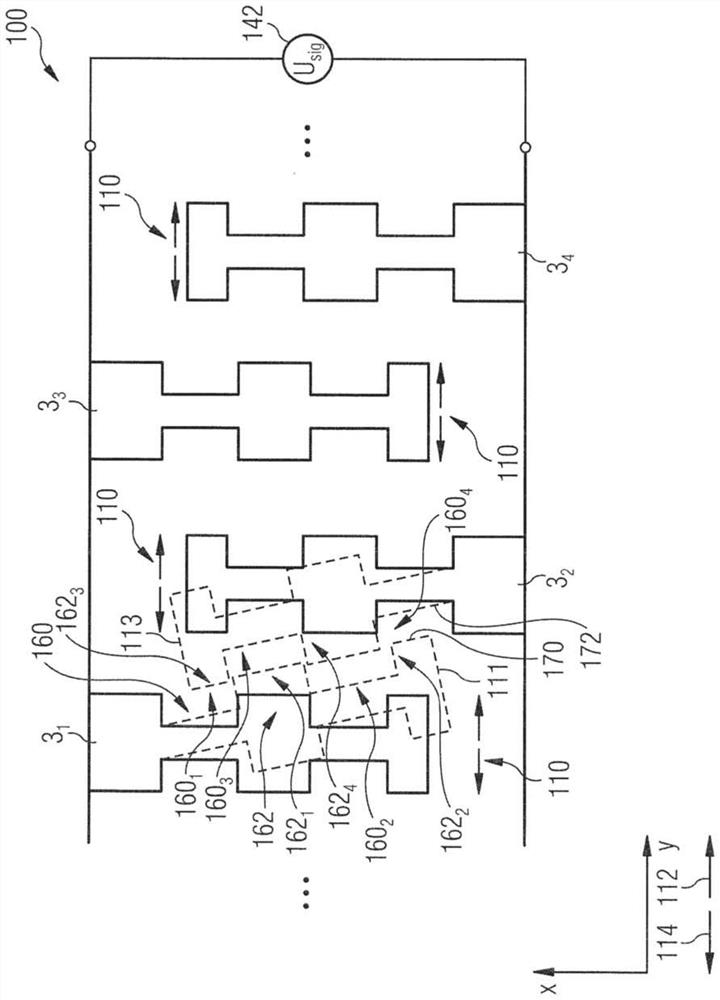

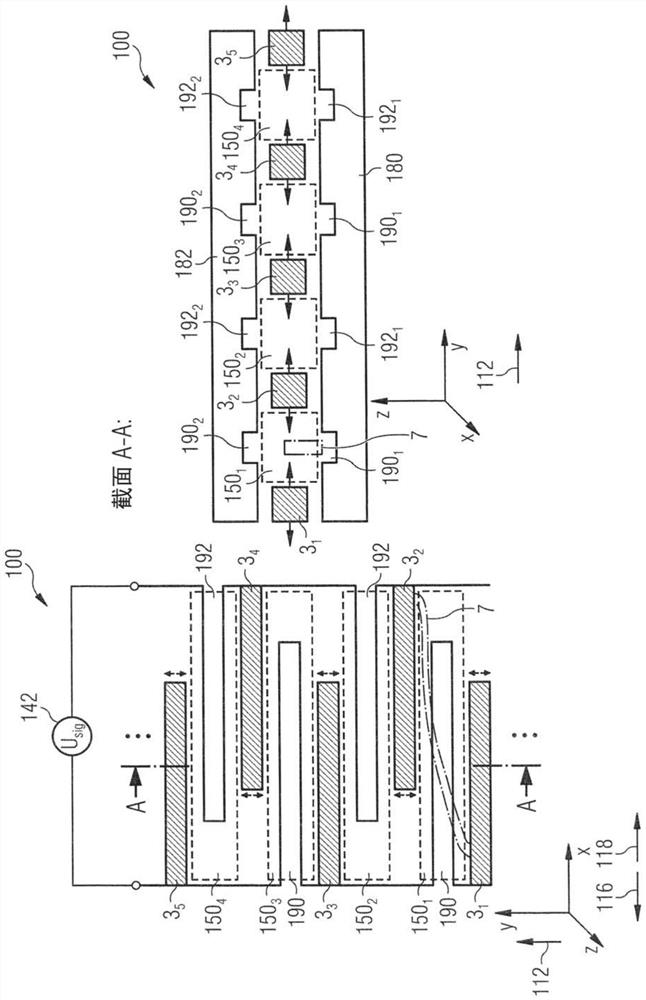

[0047] In the following, according to one embodiment, the bending transducer used comprises a centroid fiber extending in or in the direction of the second axis x. In only certain embodiments, the centroid fibers extend parallel to the second axis. The centroid fiber represents eg the axis of symmetry of the bending transducer or alternatively eg a central electrode arranged between the first electrode and the second electrode.

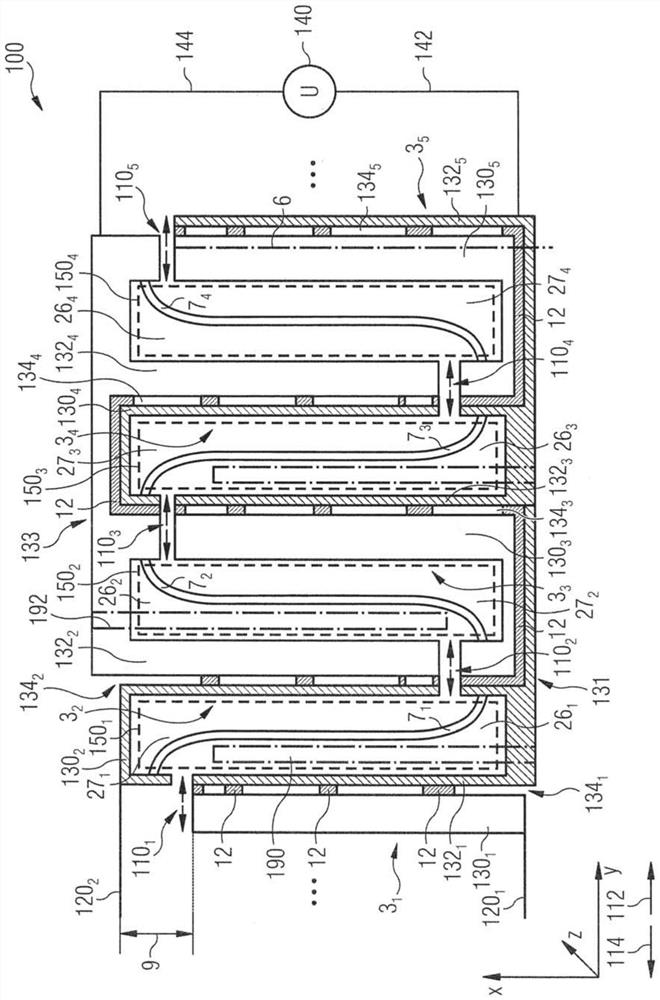

[0048] figure 1 Shows a micromachined acoustic transducer 100 comprising a plurality of curved transducers 3 suspended on one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com