Sintering and mixing method

A technology of sintering mixing and bonding materials, which is applied in the field of metallurgy, and can solve problems such as electrical failure, loss, and time-consuming equipment maintenance or replacement of the sintering mixing system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

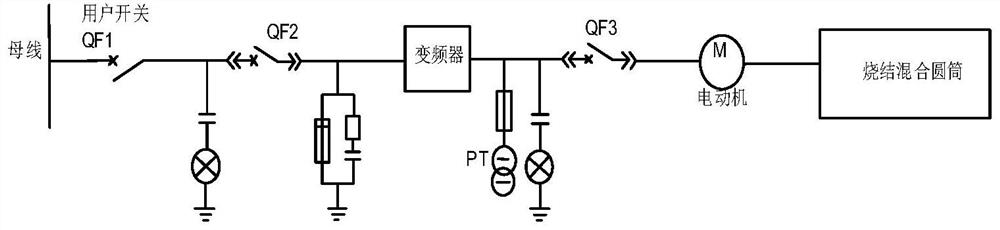

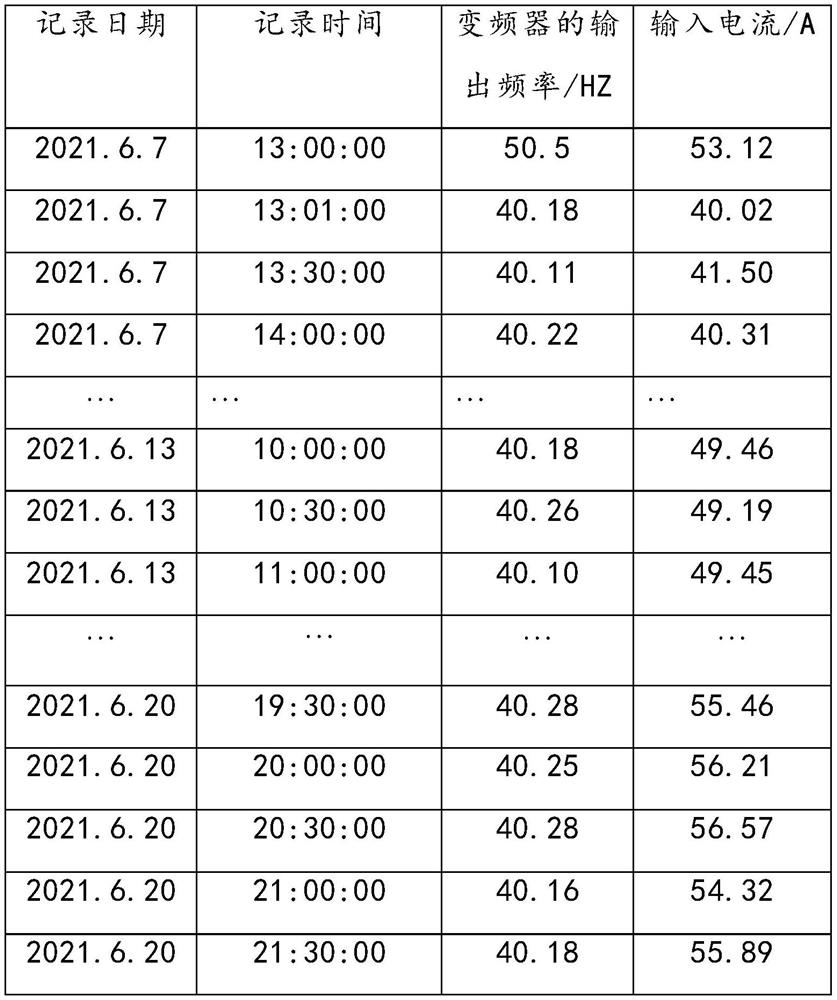

[0026] In order to make the purpose, technical solutions and advantages of the embodiments of the present application clearer, the technical solutions in the embodiments of the present application will be described below in conjunction with the drawings in the embodiments of the present application.

[0027] When the sintering mixing system is in operation, the sintering mixing cylinder rotates, causing dust to fly on site, and the dust will inevitably be sucked into the wound motor, and since the rotor of the wound motor is made of copper wire, As a result, the rotor part of the motor is prone to material jamming, and the carbon brush of the motor cannot operate normally and flexibly, resulting in the failure of the wound motor, which leads to the failure of the entire sintering and mixing system to operate normally.

[0028] If the site of the sintering mixing system is cleaned regularly, although it can solve the problem of flying dust and reduce the probability of motor fai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com