Wafer bearing system with high etching rate uniformity and wafer bearing disc structure thereof

A wafer carrying and etching rate technology, applied in discharge tubes, electrical components, circuits, etc., can solve the problems of poor etching rate uniformity and poor temperature uniformity, achieve optimal etching rate uniformity, and improve temperature uniformity. Sexuality, the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

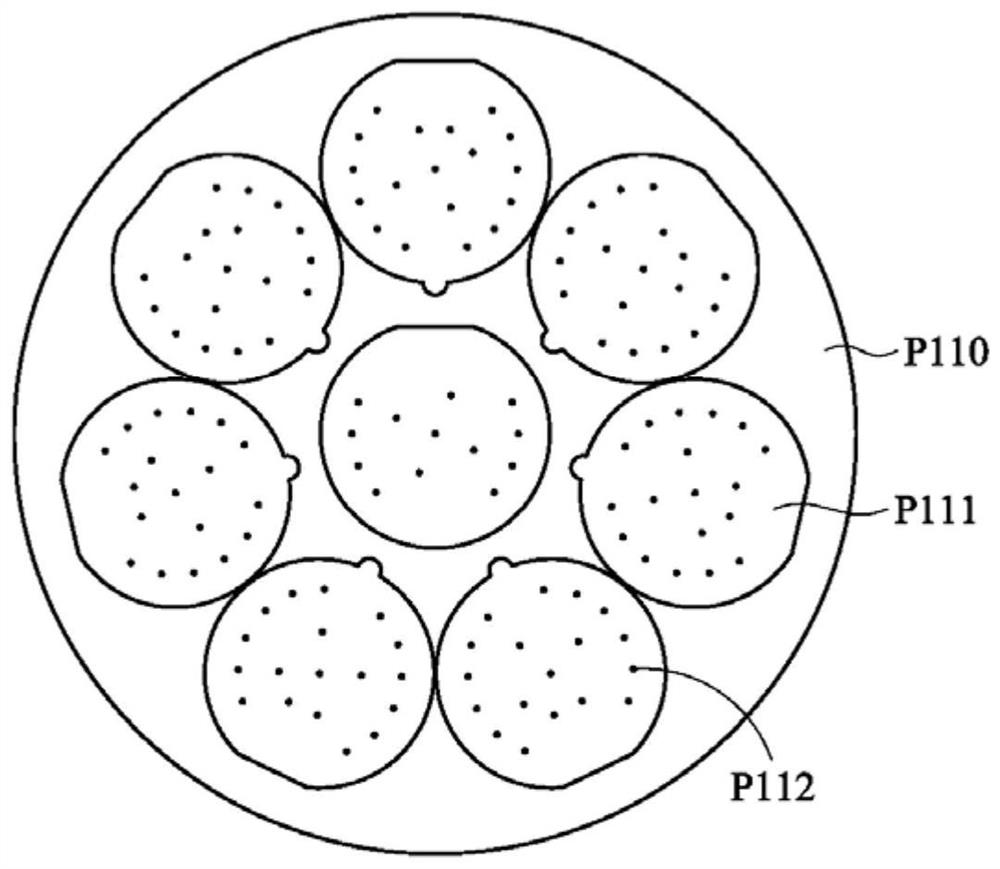

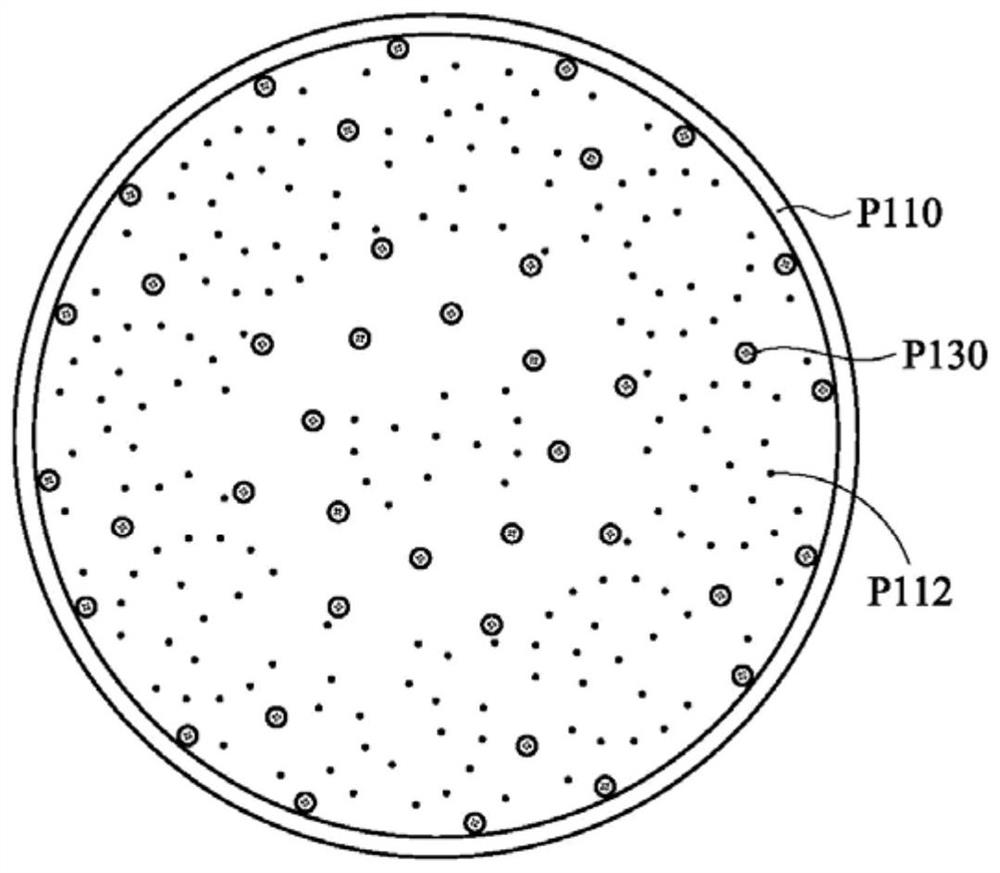

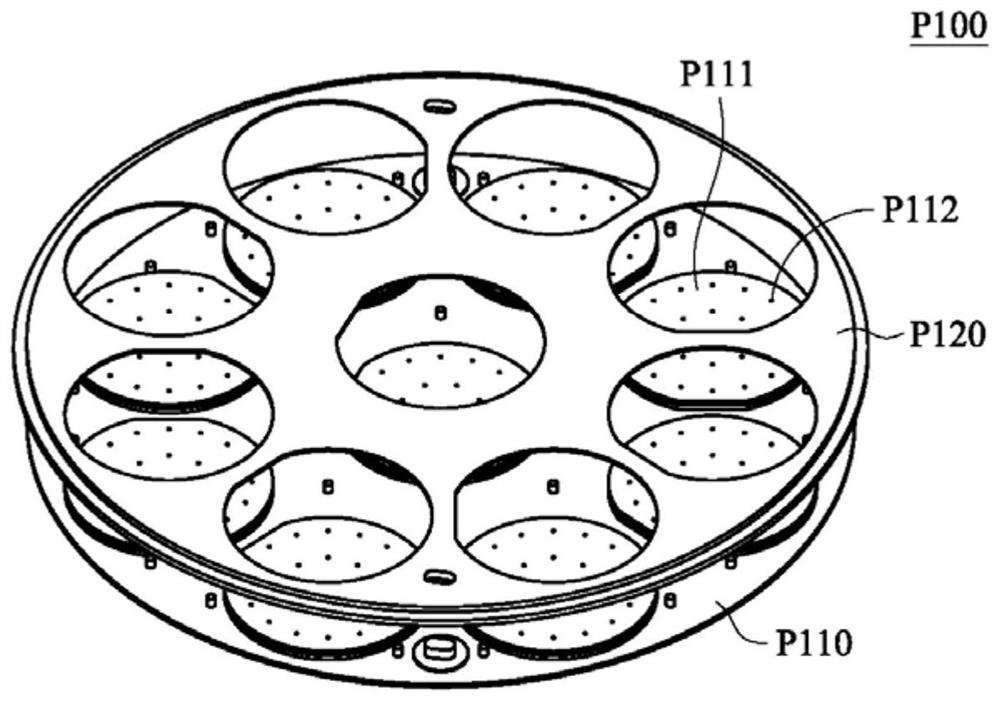

[0067] As shown in FIG. 4 , the present embodiment is a wafer carrier system 100 with high etch rate uniformity, which includes: a lower electrode base plate 110 ; a lower electrode upper cover plate 120 ; a high etch rate uniformity wafer carrier 130 ; And the outgassing seal ring 140 .

[0068] The lower electrode base plate 110 is used for connecting a radio frequency (RF), so that the positively charged particles are attracted by the negative bias and accelerated, and then almost vertically perform ion-bombardment on the wafer placed on the bearing surface 131a ) to produce an etch rate response. In order to control or cool the wafer, the lower electrode base plate 110 has cooling medium injection holes 111 , cooling medium discharge holes 112 and a plurality of air inlet holes 113 for cooling medium.

[0069] The cooling medium injection hole 111 can be used to inject a cooling medium such as water, and the cooling medium discharge hole 112 can be used to discharge the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com