Hand-held AGV tracking PID parameter debugging system and use method thereof

A parameter debugging, hand-held technology, applied in the field of intelligent logistics, can solve the problems of inconvenient portability and cumbersome debugging process, and achieve the effect of improving debugging efficiency, shortening debugging process and reducing load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

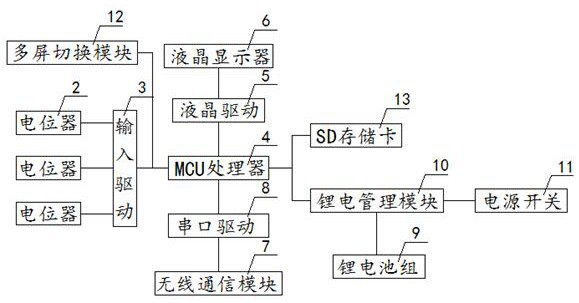

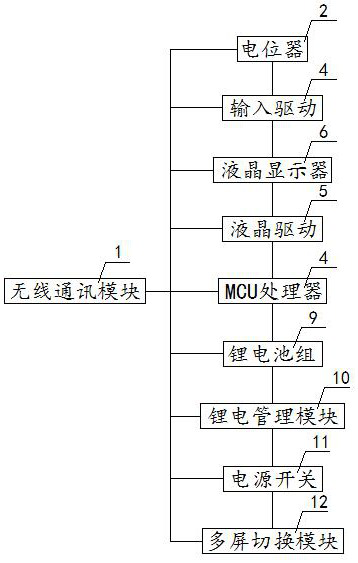

[0058] see Figure 1 to Figure 2 , a handheld AGV tracking PID parameter debugging system, including a wireless control module 1 and a wireless communication module 7, the wireless communication module 7 is wirelessly connected to the AGV trolley, and the wireless control module 1 includes a regulator 2, an input drive 3 , MCU processor 4, liquid crystal driver 5, liquid crystal display 6, the quantity of described regulator 2 is three, and these three regulators 2 are respectively connected with three input ends of MCU processor 4 one by one by input driver 3, Three described regulators 2 are respectively used for adjusting the P, I, D value that is input in the MCU processor 4, and described liquid crystal display 6 is connected with MCU processor 4 by liquid crystal driver 5;

[0059] The wireless communication module 7 is connected with the MCU processor 4 through the serial port driver 8, and the wireless communication module 7 is used for receiving the data of the AGV tr...

Embodiment 2

[0066] Basic content is the same as embodiment 1, the difference is:

[0067] see Figure 1 to Figure 2 , the wireless control module 1 is provided with an SD memory card 13, and the SD memory card 13 is used to store data; the wireless control module 1 also includes a lithium battery pack 9, a lithium battery management module 10 and a power switch 11, the The input end of the lithium battery management module 10 is connected with the lithium battery pack 9 and the power switch 11, the output terminal of the lithium battery management module 10 is connected with the MCU processor 4, the lithium battery pack 9 supplies power for the MCU processor 4, and the power switch 11 It is used to control the lithium battery management module 10; the wireless control module 1 also includes a multi-screen switching module 12, and the multi-screen switching module 12 is connected to the MCU processor 4; the regulator 2 is an analog potentiometer or a digital pulse Encoder, and the regulat...

Embodiment 3

[0069] Basic content is the same as embodiment 1, the difference is:

[0070] see Figure 1 to Figure 2 , in the adjustment step, manually adjusting the regulator 2 refers to changing the pulse signal generated by the regulator 2 by turning the knob; in the data processing step, receiving in real time means that the MCU processor 4 obtains the regulator through a hardware interrupt mode. 2 pulse signal; in the data communication step, real-time feedback refers to that the AGV car collects the AGV car data through the head magnetic navigation sensor, and then transmits the data to the MCU processor 4 in real time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com