Electronic pump assembly high and low temperature comprehensive performance test bench

A comprehensive performance, high and low temperature technology, used in pump testing, liquid variable capacity machinery, machines/engines, etc., can solve the problems of inability to test various report requirements, simple structure of oil supply system, inability to test various product tests, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the following examples are specifically described in conjunction with the accompanying drawings.

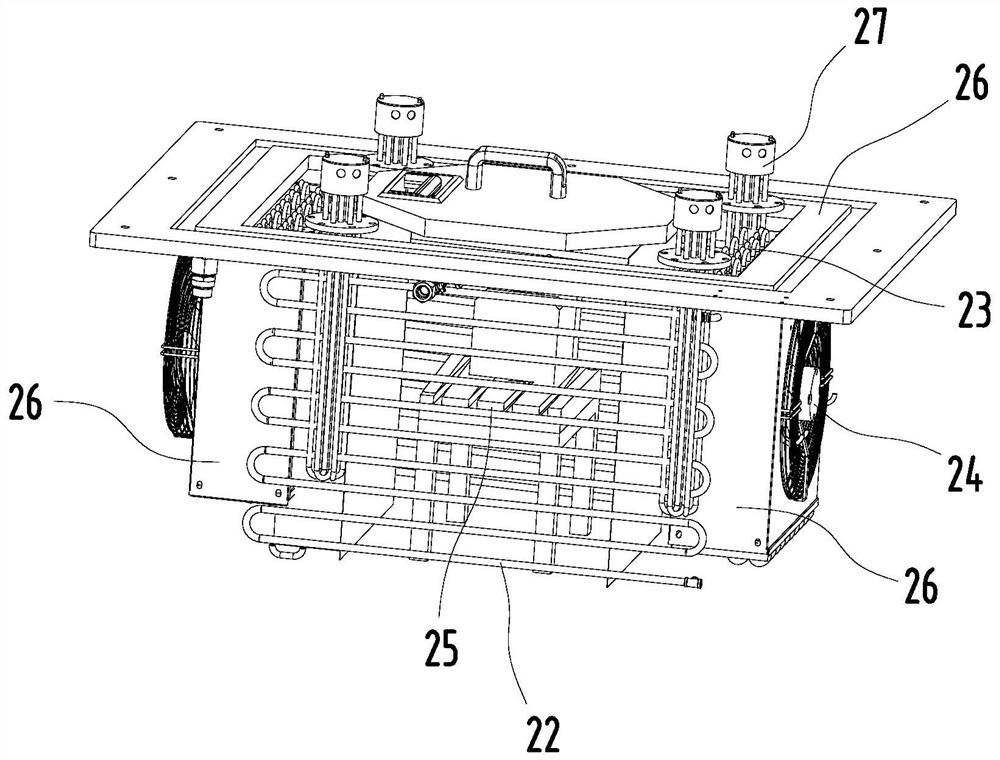

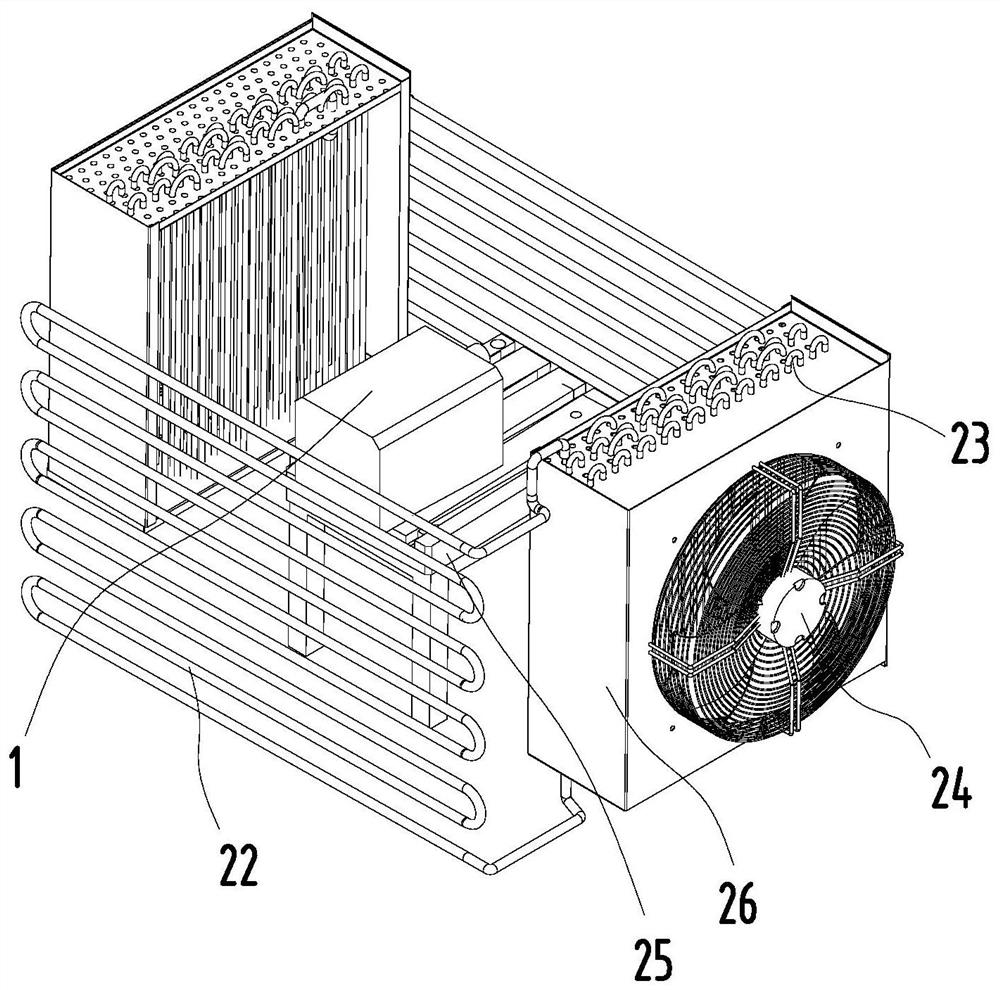

[0024] The present invention discloses an electronic pump assembly high and low temperature composite performance test bench, such as figure 1 As shown, it includes a pump body 1 to be tested, the tank 2, the oil temperature machine 3, the oil storage tank 4, the detection oil passage 5, and the detection air circuit 6, and the pump body 1 to be tested is mounted in the test tank 2, the oil temperature machine 3 The fuel tank 4 is connected to the test fuel tank 2, respectively, and the detection oil passage 5 and the detection air circuit 6 are connected to the pump body 1 to be tested to detect the pump body 1, respectively.

[0025] In detail, the detection oil passage 5 includes a water pipe, a pressure sensor group 52, a valve group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com