Convenient and fast masonry horizontal slurry laying device

A level and convenient technology, applied in the direction of construction, building structure, building materials processing, etc., can solve the problems of heavy masonry workload, insufficient number of masonry personnel, waste of mortar resources, etc., and meet the requirements of reducing operation proficiency , Avoid mortar failure and waste, and improve the efficiency of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

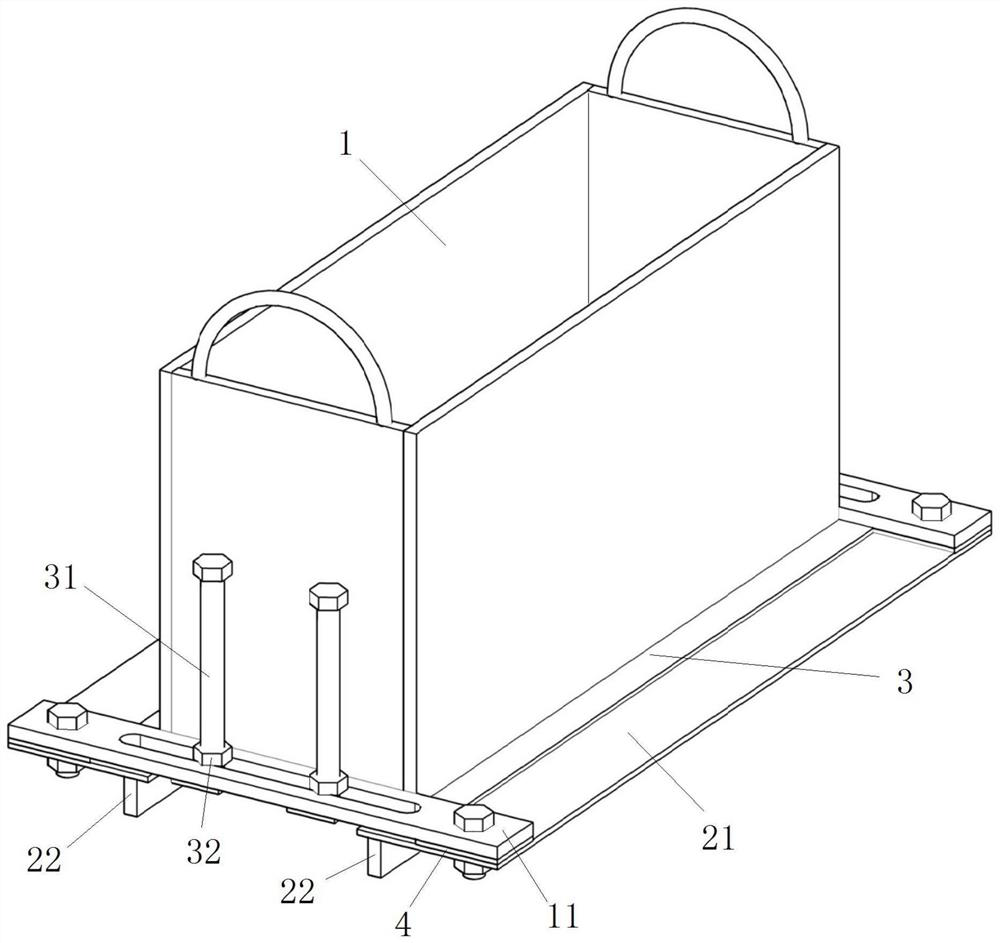

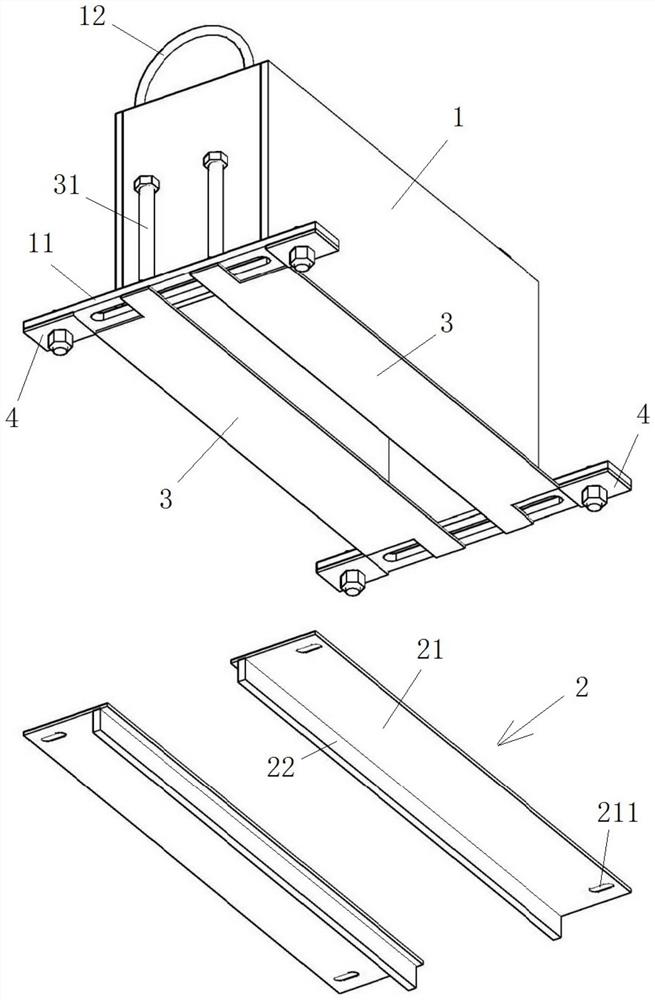

[0032] See Figure 1 to Figure 4 , a convenient masonry horizontal grouting device, including a box body 1, two brick clips 2 and two movable panels 3, wherein:

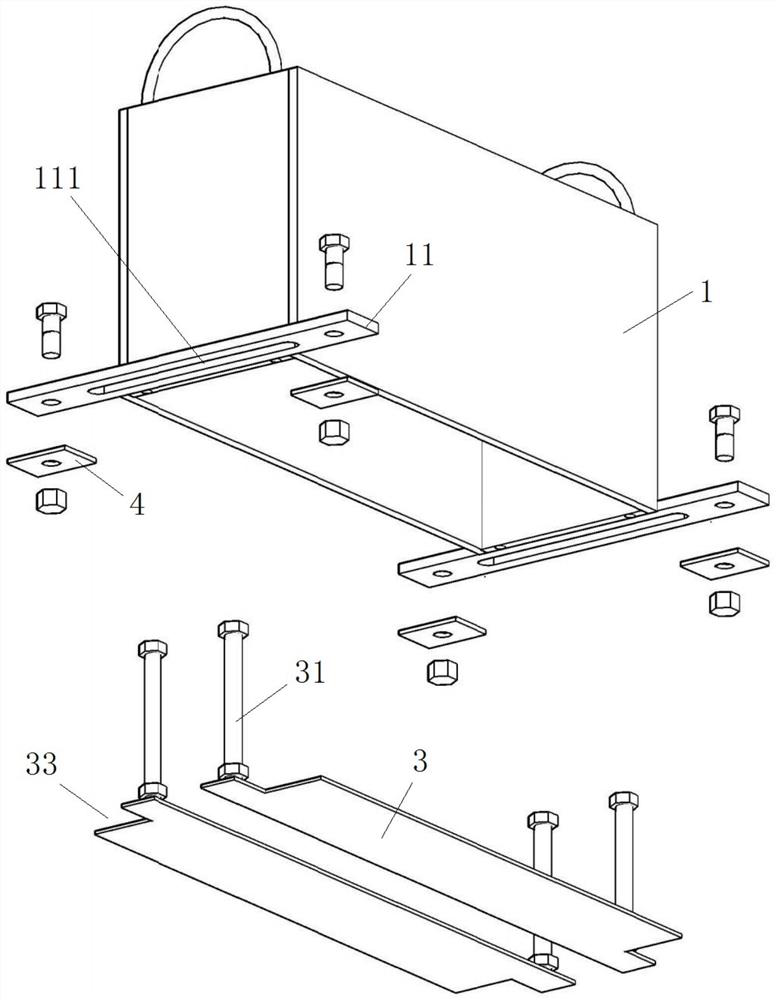

[0033] See image 3 , the top side and the bottom side of the box body 1 are provided with openings. The front and rear side walls of the box body 1 are fixedly connected with strip plates 11, and the strip plates 11 are arranged along the transverse direction. Both ends of the top wall of the strip plate 11 are provided with connection holes, and the middle part of the top wall of the strip plate 11 is provided with strip holes 111 , and the strip holes 111 are arranged along the transver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com